Rockbolt construction drill method and tube component for rockbolt construction drill

A technology for the construction of tubular components and anchor rods, which is applied in the direction of drill pipes, drill pipes, casings, etc., which can solve the problems of slow work efficiency, complicated procedures, and large disturbance of the soil layer, and achieve simple structure, simple procedures, and good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

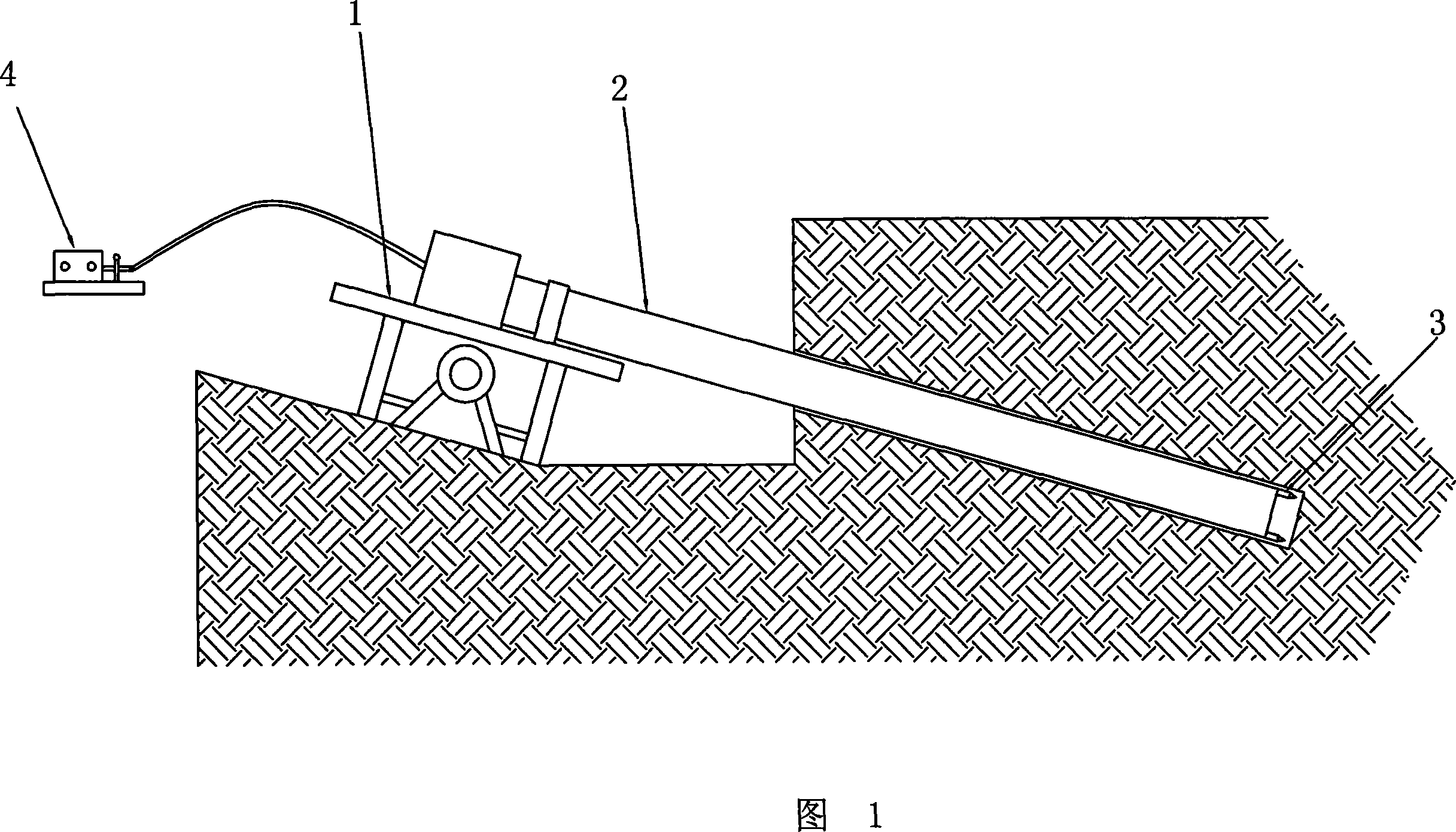

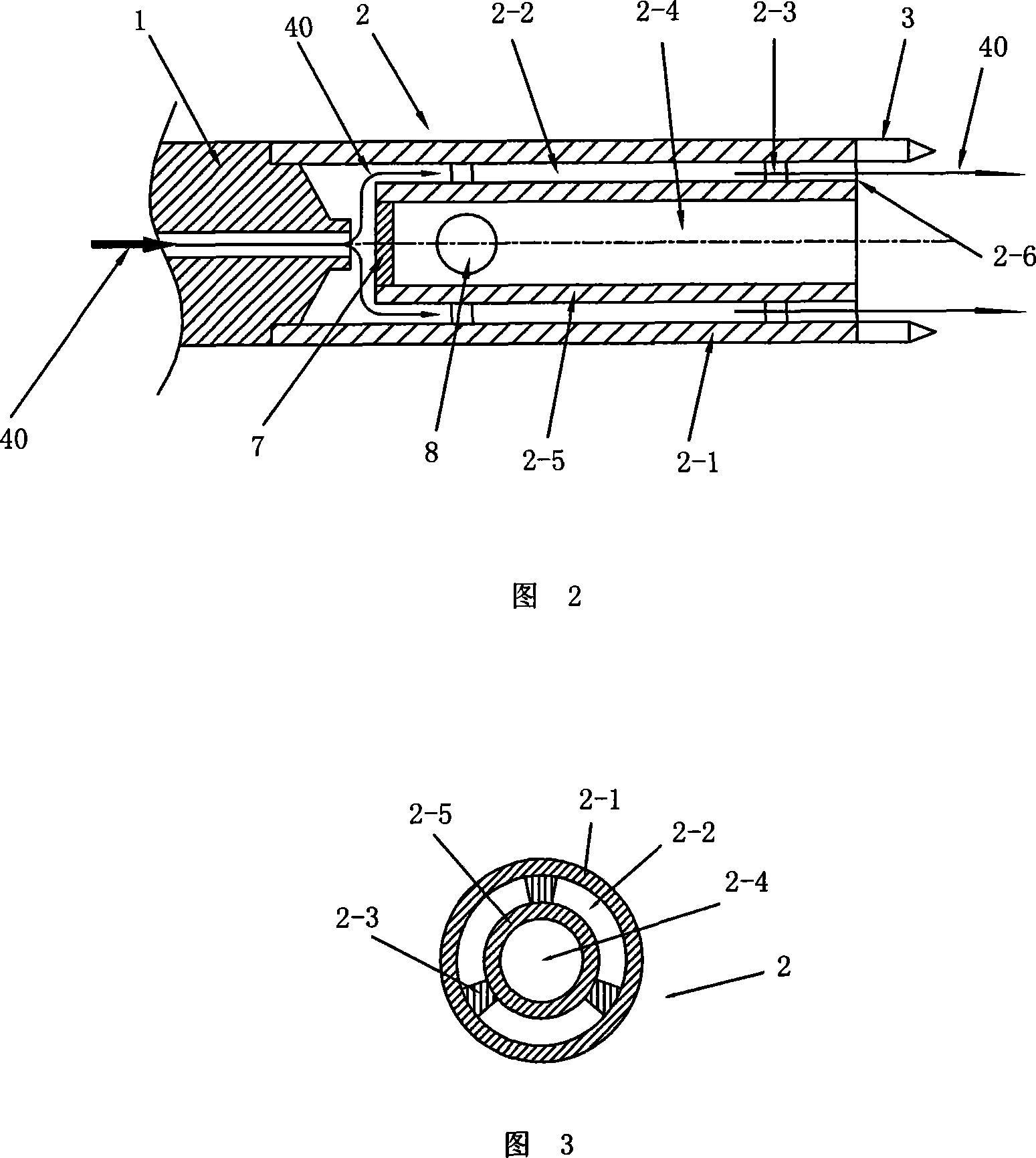

[0029] As shown in FIG. 1 , the present invention provides a tubular member 2 for anchor rod construction drilling, which is used to connect a drill bit 3 and a drilling machine 1, and is driven by the drilling machine 1 to carry out rotary drilling. As shown in FIG. 2 and FIG. 3 , the tubular member 2 includes an outer tube 2 - 1 , one end of which is connected to the joint of the drill 1 , and the other end is connected to the drill bit 3 . In the cavity in the outer tube 2-1, an inner tube 2-5 is also sleeved. The outer diameter of the inner tube 2-5 is smaller than the inner diameter of the outer tube 2-1, and there are several point-like supports 2-5 between them. 3 Support and fix it so that it forms an integral part without blocking the interlayer channel between the inner and outer tubes, and the interlayer channel formed between the inner wall of the outer tube 2-1 and the outer wall of the inner tube 2-5 constitutes the drainage channel 2 -2. During the drilling pro...

Embodiment 2

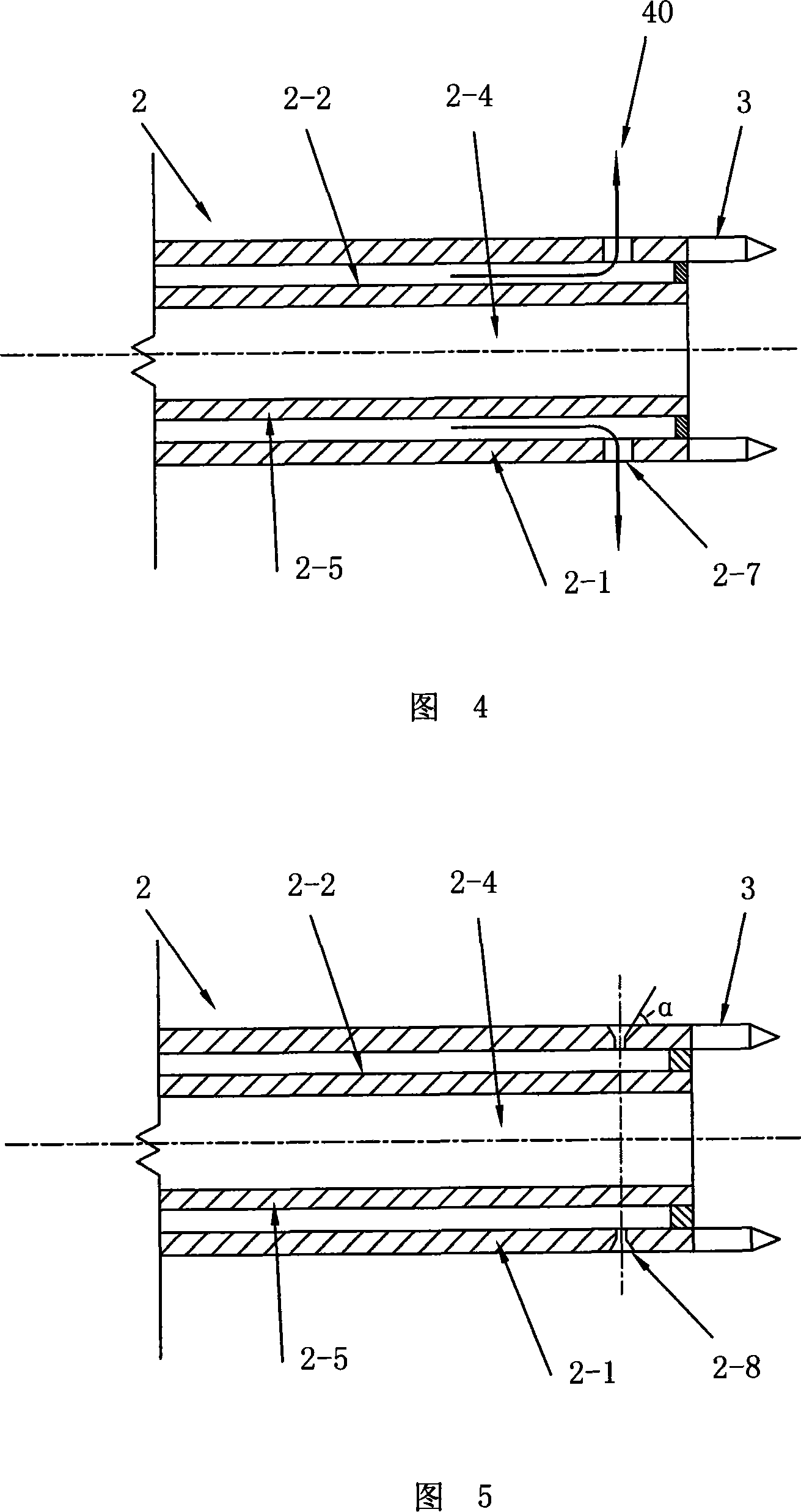

[0031]As shown in Fig. 4, the tubular member of this embodiment is also used to connect the drill bit 3 and the drilling machine 1, and is driven by the drilling machine 1 for rotary drilling. The tubular member 2 also includes an outer tube 2-1, one end of which is connected to the joint of the drilling machine 1, and the other end is connected to the drill bit 3, that is, the drill bit 3 is mounted on the front end of the tubular member 2. In the hollow channel of the outer tube 2-1, an inner tube 2-5 is also sleeved. The outer diameter of the inner tube 2-5 is smaller than the inner diameter of the outer tube 2-1, and the interlayer gap formed between the two forms a The drainage channel 2-2, the liquid 40 can be introduced into the drainage channel 2-2 through the drill 1. In this embodiment, one or more water outlets 2-7 or nozzles 2-8 (as shown in Figure 5 ) are provided on the front end wall of the outer pipe 2-1, and the water outlets 2-7 or nozzles 2- 8. It is either...

Embodiment 3

[0033] In this embodiment, the adopted tubular members and other supporting facilities are basically the same as in Embodiment 2, the difference is that the pump 4 of this embodiment adopts a high-pressure pump, and the pressure value of the liquid provided by the high-pressure pump is 0.5MPa~50Mpa between. In this embodiment, the high-pressure liquid flows out through the nozzle 2-8 or the water outlet 2-7 to form a high-pressure jet, which impacts the soil on the wall of the anchor hole, which can better roughen the wall of the hole and form an enlarged anchor hole. Greatly improve the frictional resistance of the anchor and improve the pullout resistance of the anchor. In particular, when the pullout force of the required bolt is large, a high pressure of 8-50Mpa can be used to form a larger enlarged head at the anchorage section. If the required pull-out resistance is not particularly large, a high pressure of 0.5-8Mpa can be used to roughen the hole wall, or form a small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com