Closed type helical hole-protecting drill and using method thereof for drilling of soft coal bed

A soft coal seam, closed technology, used in drill bits, drill pipes, drill pipes, etc., can solve the problems of high drilling resistance and low slag discharge efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

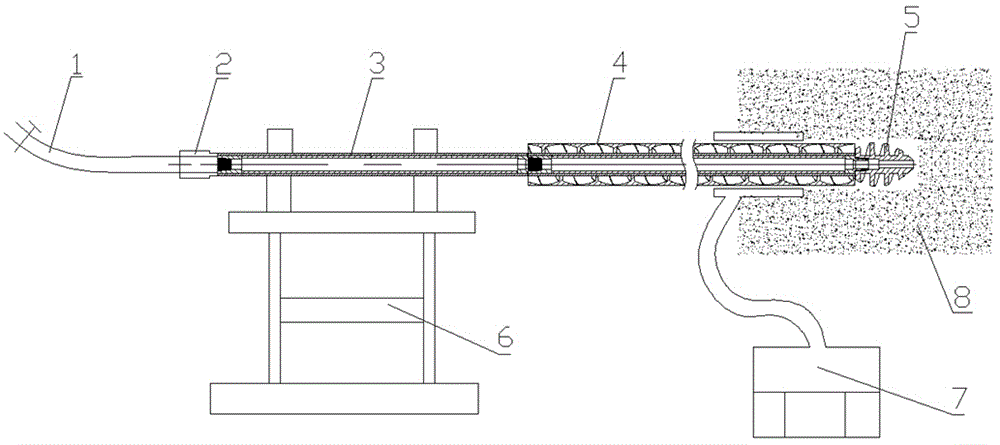

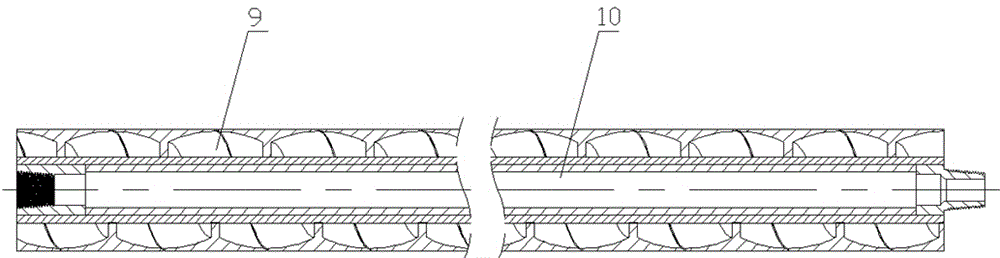

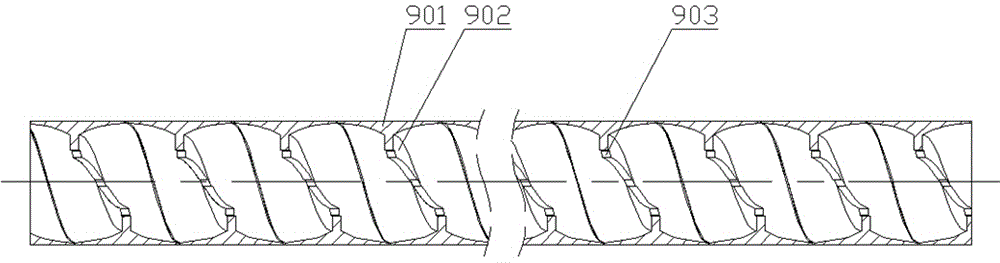

[0029] Embodiment one: if Figure 1 to Figure 8 As shown, the present invention is used for drilling into soft coal seam closed type helical hole protection drilling tool and using method thereof, comprises closed type helical hole protection drill rod 4, helical slag guide bit 5, and helical slag guide bit 5 is installed on the closed helical helical The front end of hole protection drilling rod 4. The closed spiral hole protection drill rod 4 is composed of a closed spiral hole protection blade 9 and a multi-edge drill rod body 10 . The closed spiral hole-protecting blade 9 is composed of a spiral blade top 901 and a spiral petiole 902. The width of the spiral blade top 901 is greater than that of the spiral petiole 902. The structures of the spiral blade top 901 and the spiral petiole 902 are designed in two ways: no holes or holes. The spiral blade tops 901 are connected to form a closed hole protection space, and a slag discharge space is formed between the spiral petiol...

Embodiment 2

[0037] Embodiment two: if Figure 9 , Figure 10 As shown, the difference from Embodiment 1 is that the connection mode of the drill pipe joint is changed. The plug-in male joint 1105 is designed as a hexagonal structure, and the plug-in female joint 1104 is set to correspond to the plug-in male joint 1105. Internal hexagonal structure, plug-in connection, can realize the reverse of the drill pipe.

Embodiment 3

[0038] Embodiment three: as Figure 11 , Figure 12 As shown, the difference from Embodiment 1 is that a round hole structure 15 is provided on the spiral petiole 902, and a slag discharge channel is formed between the spiral petiole 902 of the closed spiral hole guard blade 9. Using this structure, the drill pipe and the rubber hose 1 at one end It is connected with the air supply pipe of the roadway, and the other end is connected with the air supply device 2 at the tail of the drill to implement ventilation auxiliary slag discharge and improve the efficiency of slag discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com