Automatic drill pipe loading device applied to downhole hydraulic drilling rig and having drill pipe storage function

A technology for hydraulic drilling rigs and rod devices, which is applied in the field of automatic rod loading devices and devices for adding drill rods. Space, the effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings. For convenience of description, the figure 1 The upper middle is defined as the front, and the lower is defined as the rear.

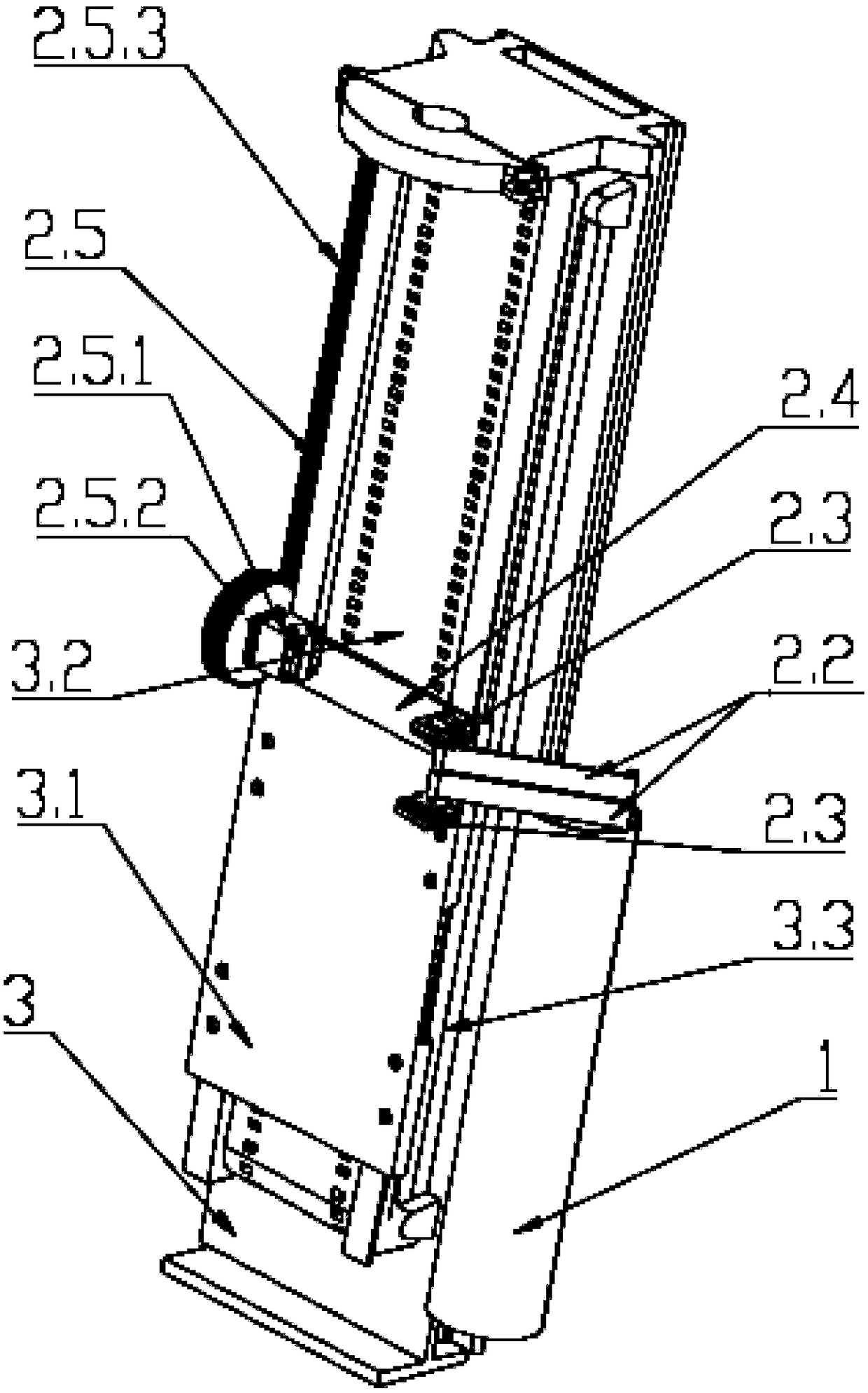

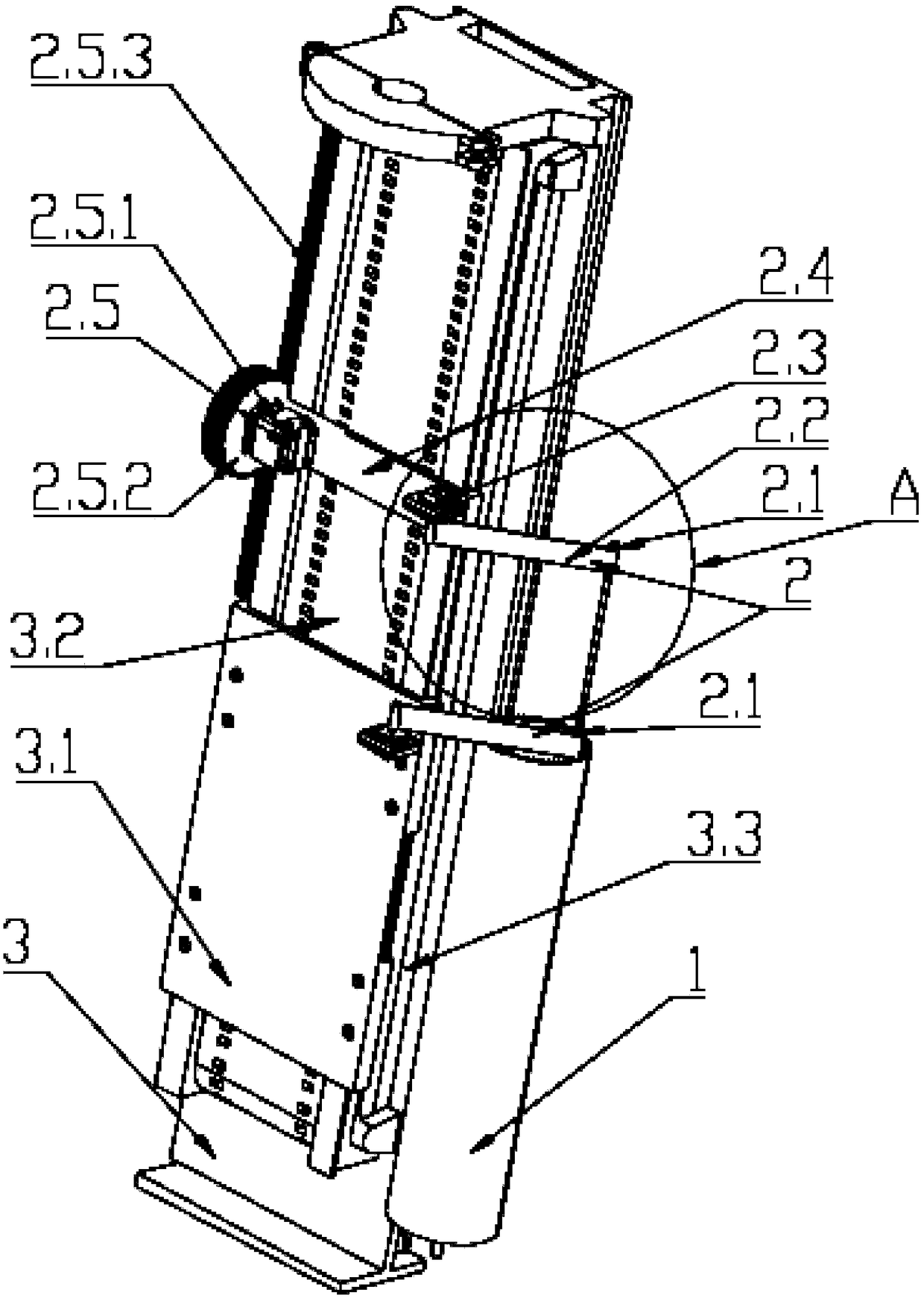

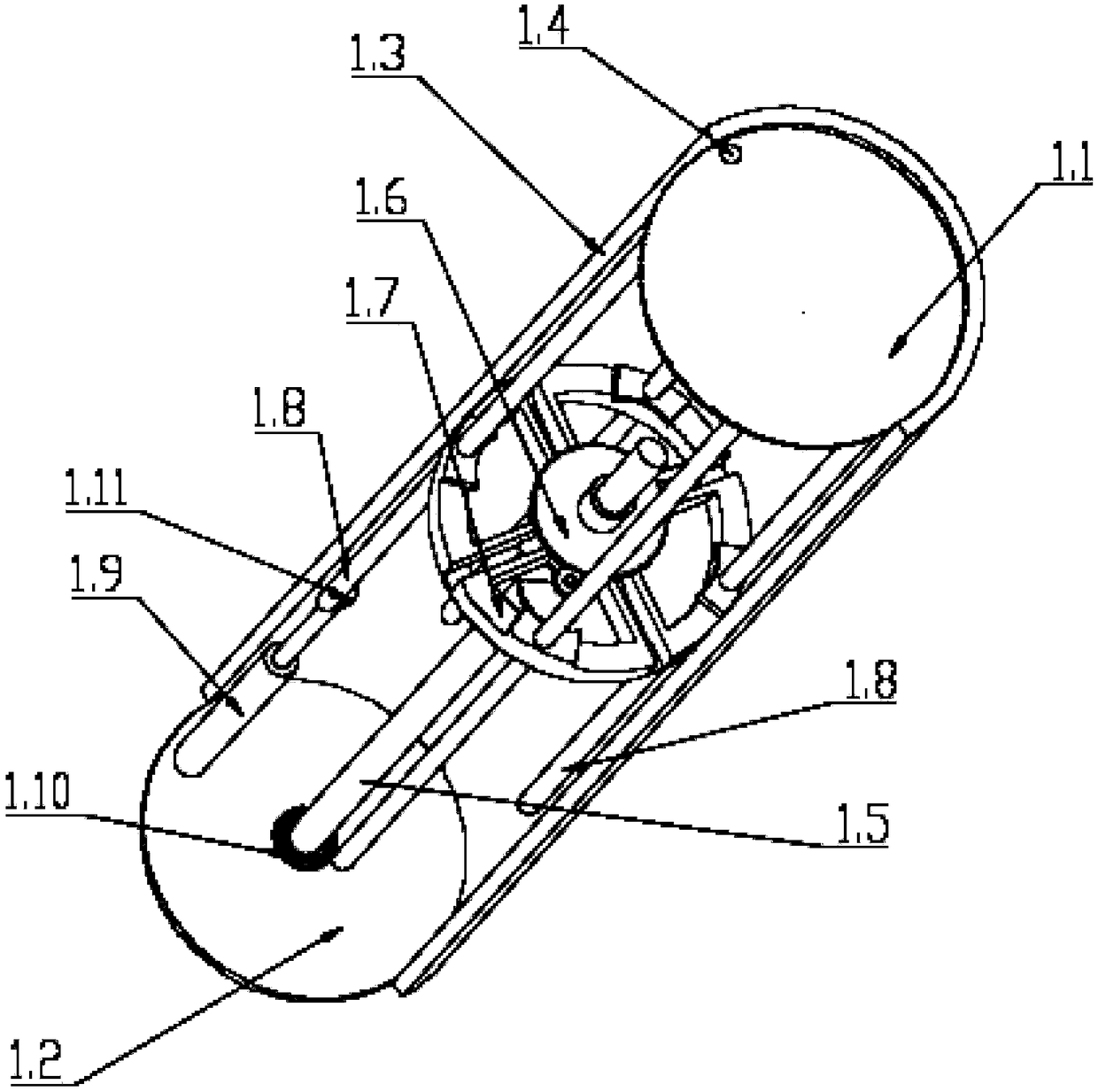

[0034] Such as Figure 1 to Figure 5 As shown, an automatic rod loading device for an underground hydraulic drilling rig with a rod storage function, including a drilling arm 3, the drilling rig is installed on the drilling arm 3 through a drilling rig slide plate 3.1, the upper end of the drilling arm 3 has a chain plate 3.2, and the drilling arm 3 There are guide rails 3.3 on both sides of the drill arm 3. The drilling rig slide plate 3.1 is clamped on the guide rails 3.3 on both sides and moves back and forth under the drive of the chain plate 3.2. The side of the drill arm 3 is provided with a drill pipe box 1 and a manipulator mechanism 2. Box 1 is fixed on the side near the initial position of the drilling rig under the guide rail 3.3; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com