Roller and rolling mill and application thereof

A technology of rolls and rolling mills, which is applied to rolls and their rolling mills and application fields. It can solve problems such as damage to product quality, scratches on the surface of work rolls, bump marks, etc., so as to prolong the service life, eliminate scratches, and improve product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples. For the experimental methods not indicating specific conditions in the following examples, follow conventional methods and conditions.

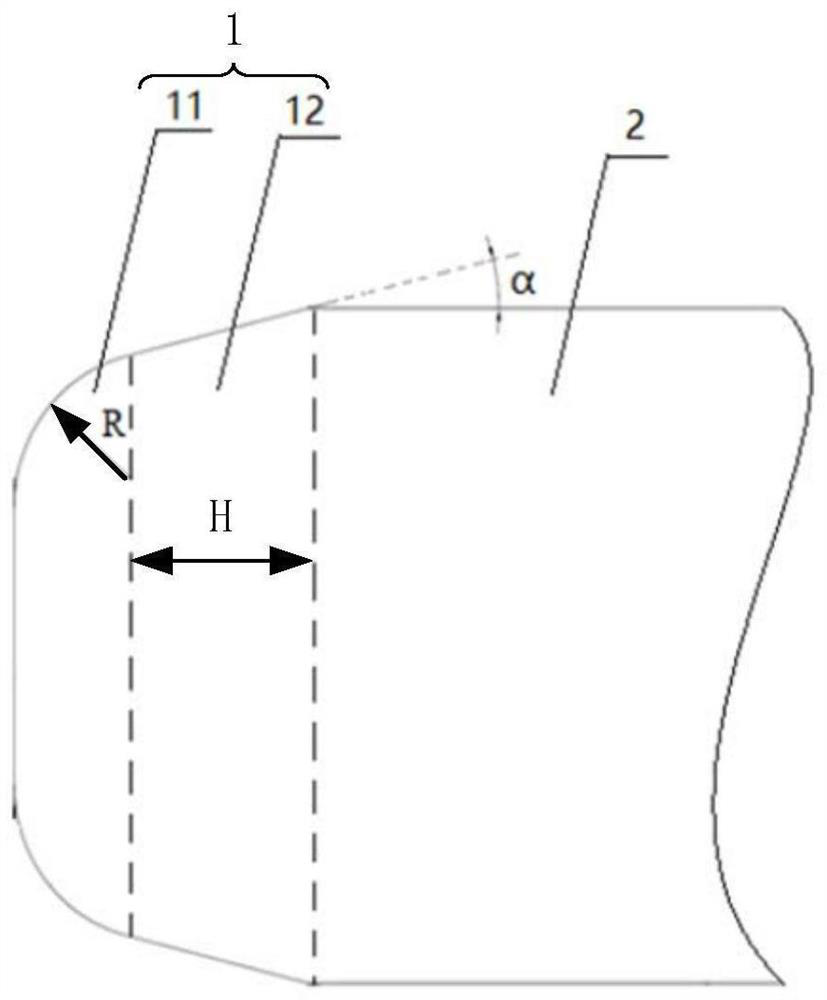

[0047] The 12# rolling mill of Shanxi Taiyuan Iron and Steel Co., Ltd. is a 20-high rolling mill, and the size specification of the first intermediate roll is the diameter of the roll body The fillet radius of the first roll end is 10 mm, the height of the second roll end is 10 mm, and the included angle between the second roll end and the roll body is 14°. When producing high-grade products such as BA boards, compared with the traditional first intermediate roll, the first intermediate roll of the present invention has better rolls for rolling mills, cold lines, and quality inspection feedback. The specific performances are as follows: ① The surface quality of the product is significantly imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com