Short distance speed-increasing type hard rock deep borehole drilling device

A technology of deep hole drilling and speed increaser, which is used in impact drilling, rotary drilling, rotary drilling rigs, etc., can solve the problems of low efficiency, poor drilling efficiency, low drilling efficiency, etc., and achieve improvement. The effect of working environment, reducing drilling cost and improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

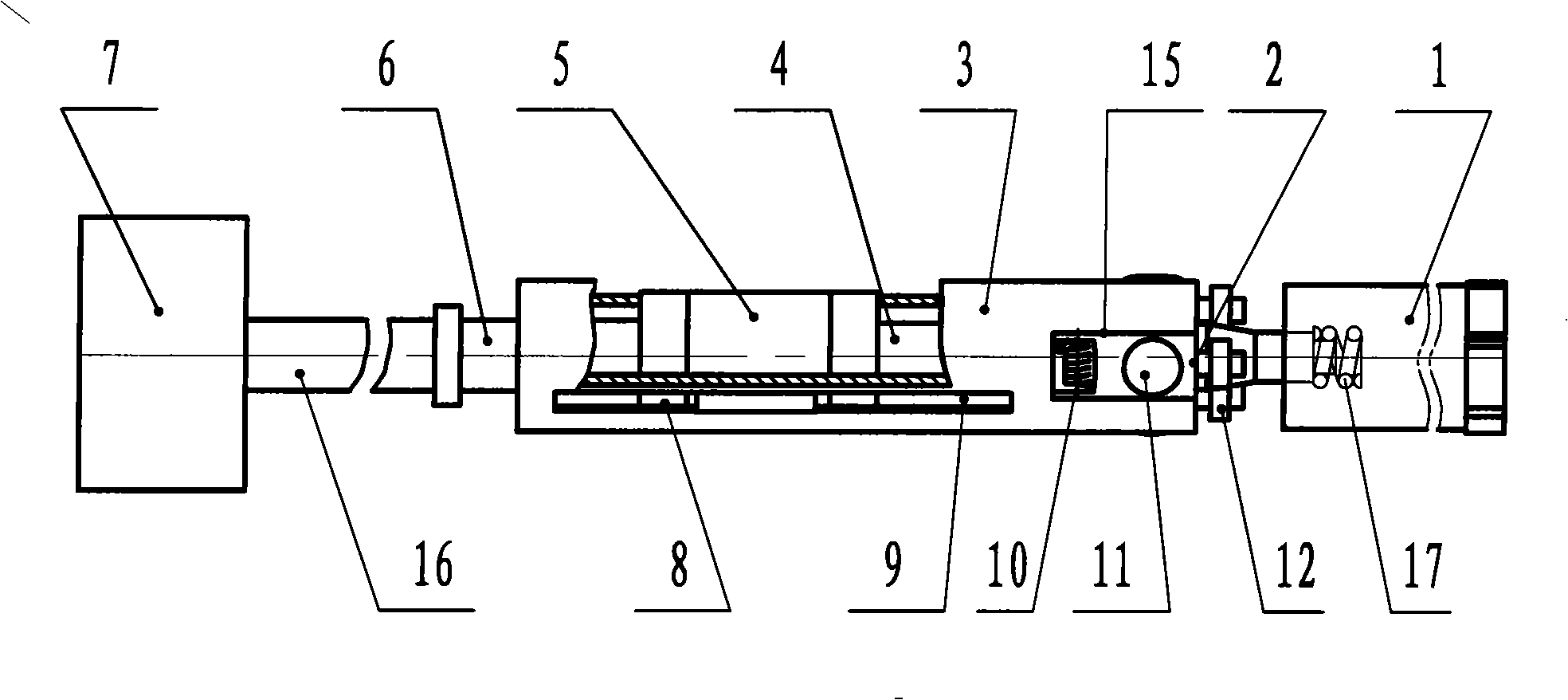

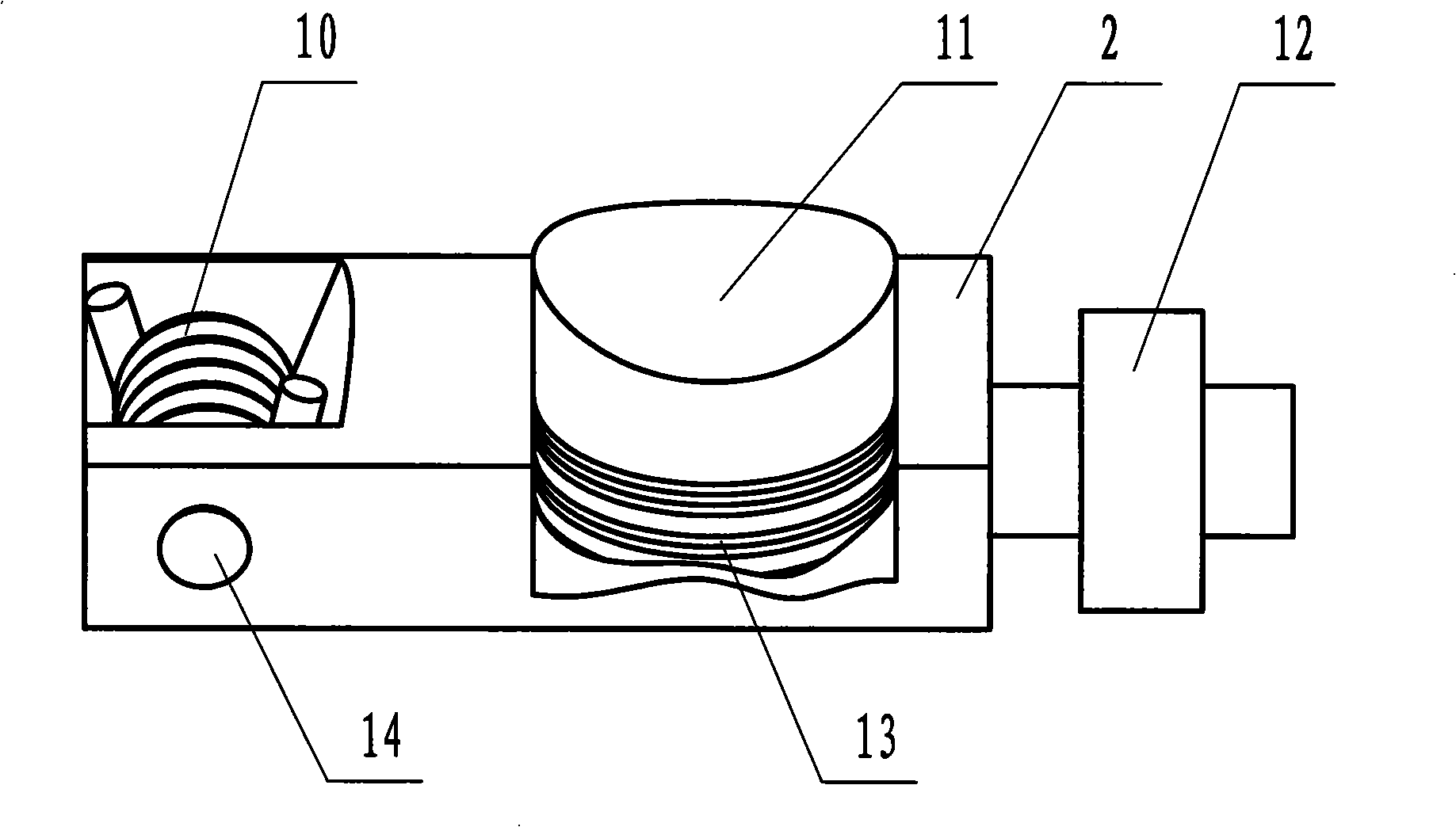

[0019] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0020] The structure of the present invention is as figure 1 As shown, it comprises a diamond drill bit 1 and a drilling rig 7 for drilling power, the power output shaft of the drilling rig 7 is connected with a drill rod 16; One end of 5 connects input shaft 6, and input shaft 6 is connected with drilling machine 7, and along with the deepening of borehole, between drilling machine 7 and input shaft 6, gradually connect the drilling rod of different length again. The other end of speed increaser 5 is provided with output shaft 4, and output shaft 4 is movably connected with drill bit 1, and the position that output shaft 4 is connected with drill bit 1 is provided with compression spring 17. The input shaft 6, the output shaft 4 and the speed increaser 5 are internally provided with interconnected water holes. The water holes lead to the inside of the diamond drill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com