Method for producing checkered steel plate by applying CSP (Cast Steel Plate) process

A patterned steel plate and process technology, applied in the field of thin slab continuous casting and rolling production, can solve the problems of long production cycle, cracking, and layered steel plates, and achieve good surface quality, improved service life, and precise plate thickness accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

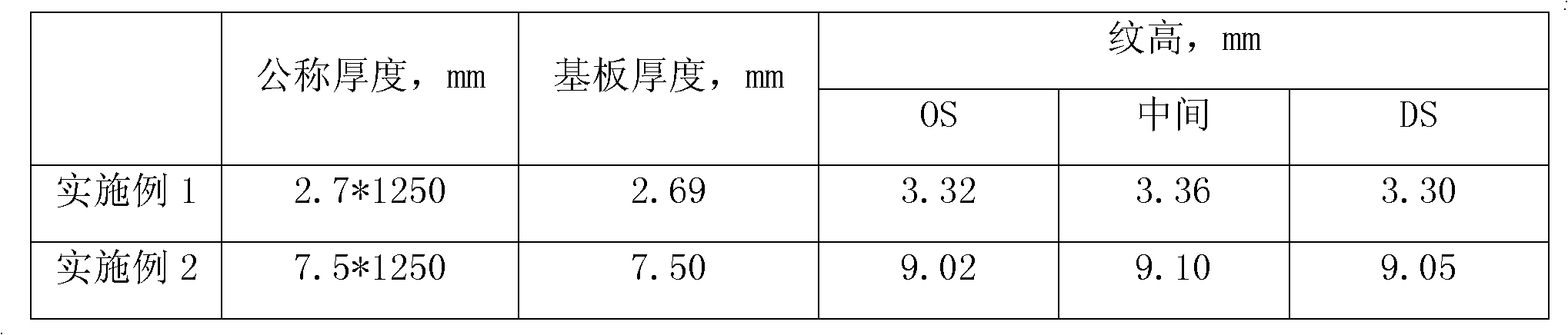

Embodiment 1

[0015] A method of applying CSP technology to produce checkered steel plates, comprising the following steps:

[0016] 1) Rolling temperature system: soaking temperature 1130°C, final rolling temperature 880°C, coiling temperature 600°C;

[0017] 2), Hot rolling reduction distribution system: F1 reduction rate 45%, F2 reduction rate 55%, F3 reduction rate 40%, F4 reduction rate 35%, F5 reduction rate 30%, F6 reduction rate 18% %, F7 reduction rate 18%;

[0018] 3) Roll matching system: F1-F6 is rolled and matched according to normal rolling, and the roll shape adopts CVC roll shape; the lower roll of F7 adopts flat roll, and the upper roll adopts grooved roll, and the roll diameter of the upper roll is 0.6 larger than that of the lower roll mm, the groove depth of the grooved roller is 4.1mm; the length of the grooved roller body is 1800mm.

[0019] 4.) Cooling after rolling: adopt laminar flow post-cooling mode.

[0020] The chemical composition (mass percentage) of the pa...

Embodiment 2

[0023] A method of applying CSP technology to produce checkered steel plates, comprising the following steps:

[0024] 1) Rolling temperature system: soaking temperature 1160°C, final rolling temperature 900°C, coiling temperature 670°C;

[0025] 2), Hot rolling reduction distribution system: F1 reduction rate 40%, F2 reduction rate 50%, F3 reduction rate 40%, F4 reduction rate 35%, F5 reduction rate 30%, F6 reduction rate 20% %, F7 reduction rate 23%;

[0026] 3) Roll matching system: F1-F6 rolls are matched according to normal rolling, and the roll shape adopts CVC roll shape; the lower roll of F7 adopts flat roll, and the upper roll adopts grooved roll, and the roll diameter of the upper roll is 1.0 larger than that of the lower roll mm, the groove depth of the grooved roller is 4.3mm; the grooved roller body has a grooved length of 1800mm.

[0027] 4.) Cooling after rolling: adopt laminar flow post-cooling mode.

[0028] The chemical composition (mass percentage) of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com