Drill pipe, and system and method for laying a pipeline

A technology for drilling pipes and drilling equipment, which is applied to drilling equipment and methods, drilling pipes, drilling equipment, etc., to achieve simple and economical tensile connections and shorten the installation and commissioning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

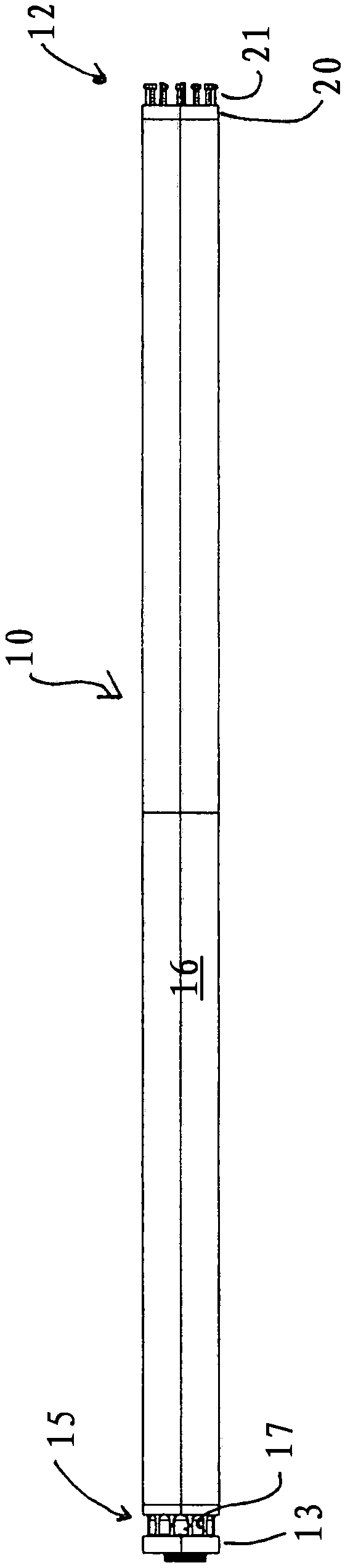

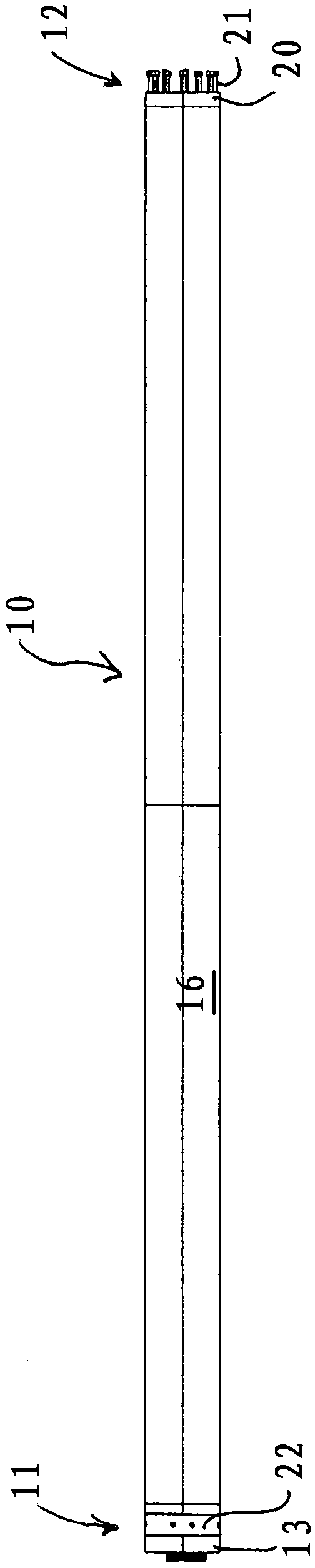

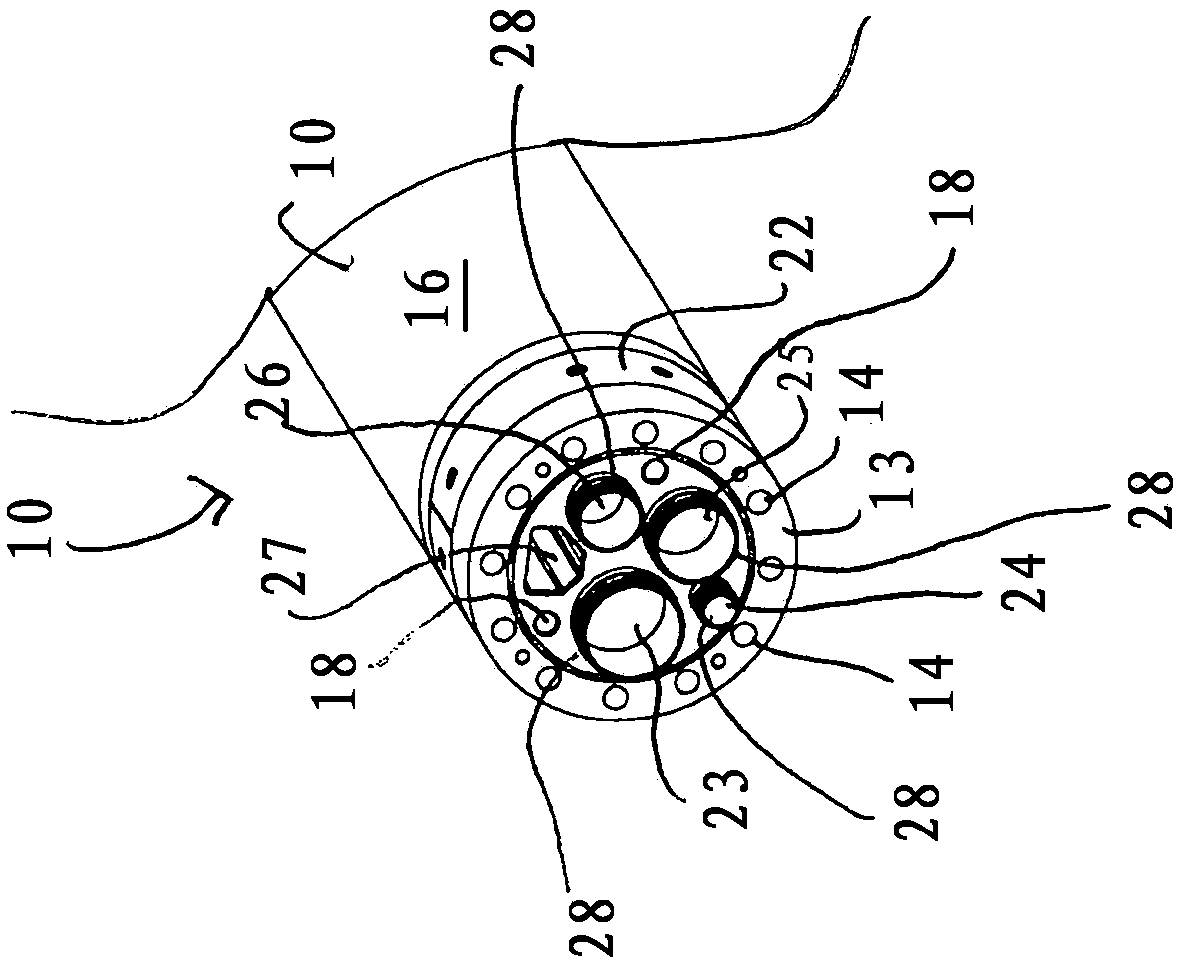

[0072] 1A, 1B show a side view of a first embodiment of a drill pipe 10 according to the present invention. The drill pipe 10 has a first connecting section 11 at its first end and a second connecting end 12 at its opposite second end, wherein the first connecting section 11 and the second connecting section Section 12 corresponds to each other because these connecting sections can be connected to each other or plugged together. The first connecting section 11 and the second connecting section 12 are arranged here such that they form a flange connection system in the first embodiment of the invention, wherein the first connecting section 11 has a supporting section 13 in which the supporting A hole 14 is provided in the section. On the rear side of the supporting section 13, a recess 15 is provided in the outer wall 16 of the drill pipe 10. (See Figures 2A to 2D). In the recessed portion 15, a void 17 is provided corresponding to the hole 14. In addition, a hole 18 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com