Valve control system

A valve control and power device technology, applied in valve details, valve devices, valve operation/release devices, etc., to solve problems such as valve neck damage and heavy weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

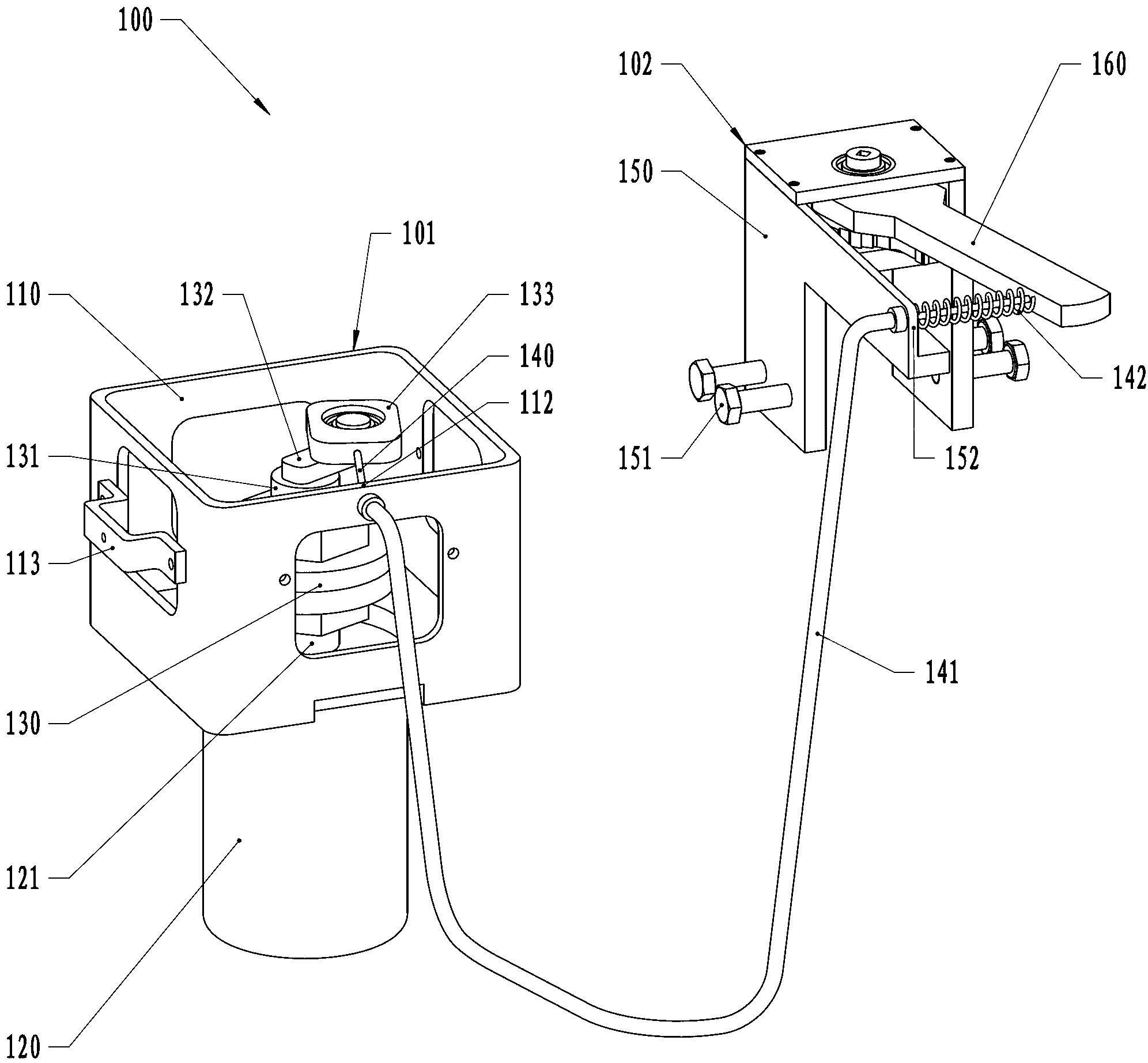

[0020] Such as figure 1 As shown, the valve control system 100 has a power device 101 and an operating device 102 .

[0021] The power unit 101 has a bracket 110, and the deceleration stepping motor 120 is fixed on the bracket 110 by screws. The lower end of the torque limiter 130 is fixed on the rotating shaft 121 of the deceleration stepping motor 120 , and the upper end of the torque limiter 130 is fixed with a reel 131 . One end of the rocker arm 132 is fixed on the reel 131 , and the other end is mounted with a plate 133 that can rotate relative to the rocker arm 132 .

[0022] The operating device 102 has a fixing frame 150 . The fixed frame 150 is installed on the valve neck of the tank body through four bolts 151 arranged at its lower end.

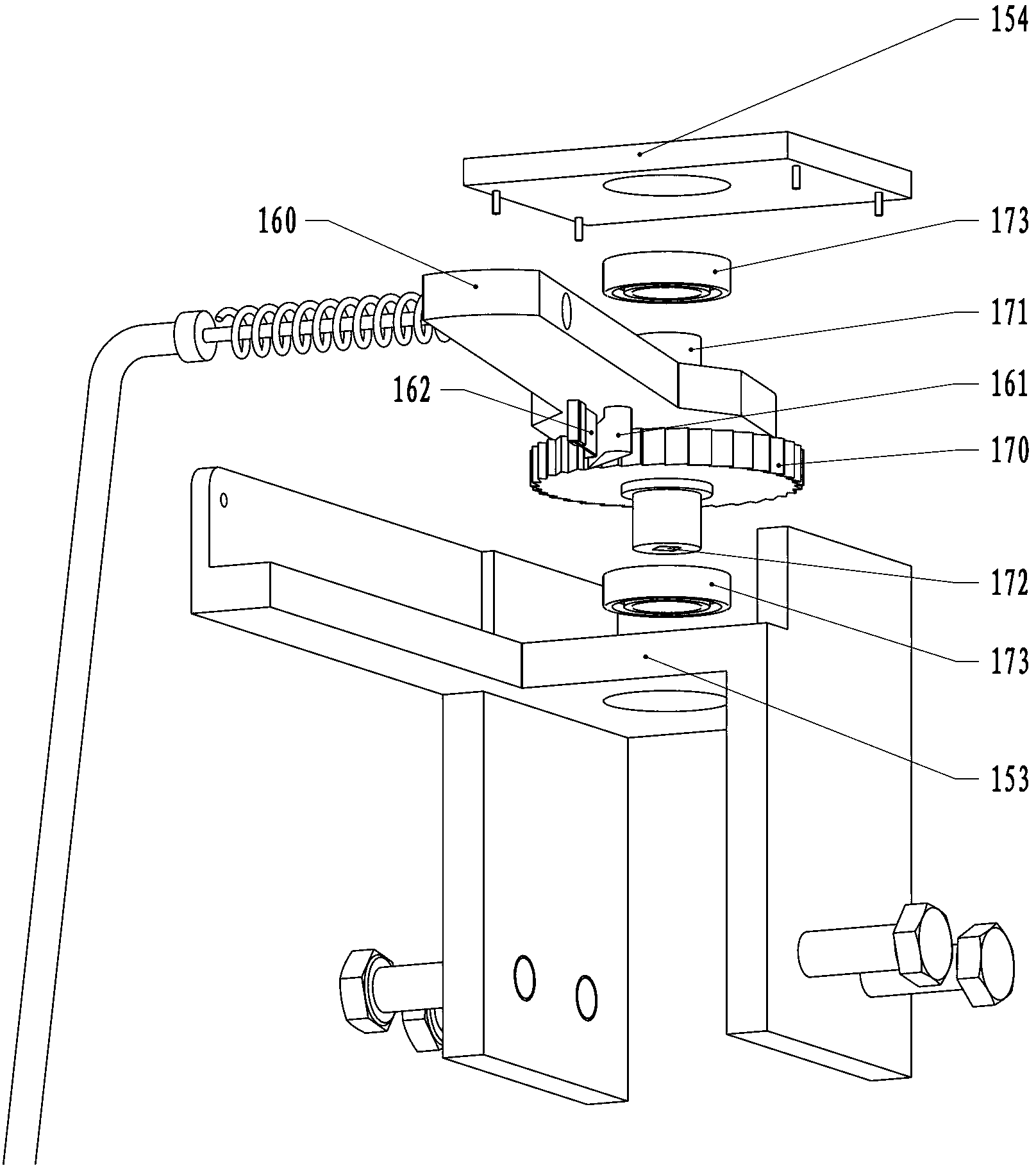

[0023] One end of the flexible cable 140 is fixed on the tail of the rocker 160, and the other end is fixed on the plate 133 as the power output end. The flexible cable sleeve 141 is set on the outside of the flexible cable, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com