DRS double-rib beam type prefabricated stair

A rib-shaped and beam-type technology is applied in the field of DRS double-rib beam-type prefabricated stairs, which can solve the problems of high technical requirements, unsightly appearance, and difficulty in construction, and achieves increased manufacturing process difficulty, simple prefabrication process, and reduced installation weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

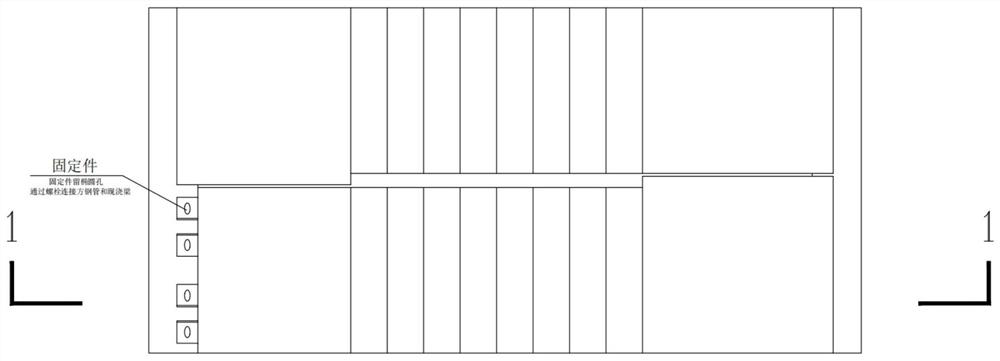

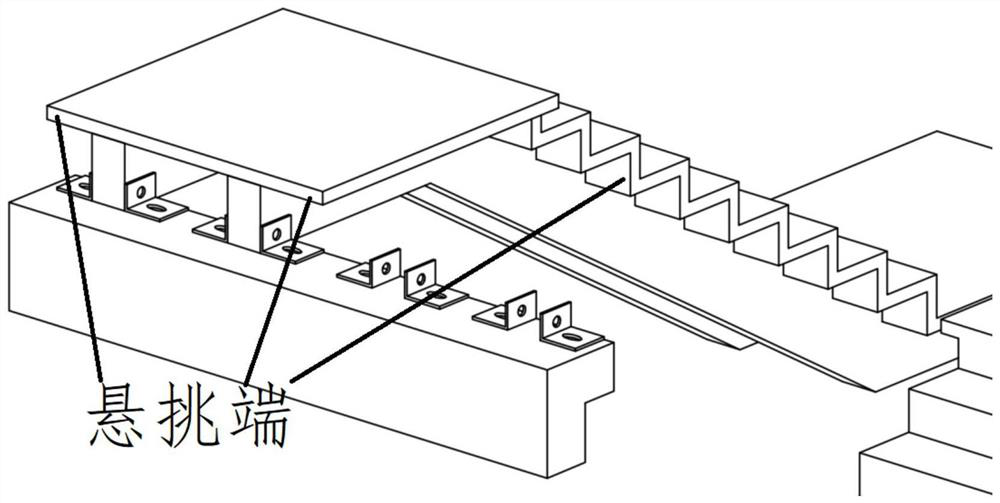

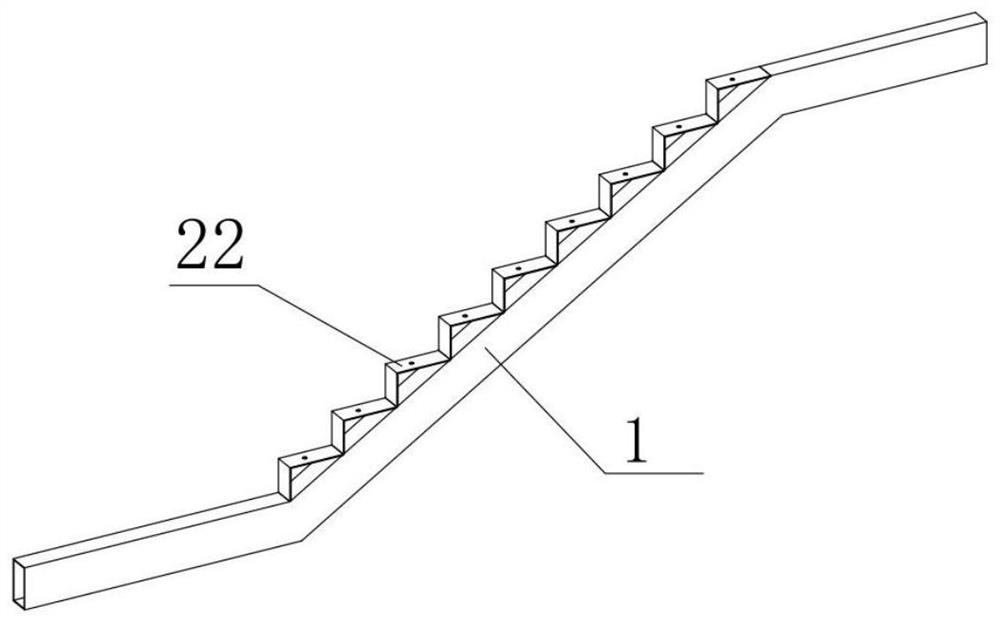

[0041]A DRS double-rib beam-type prefabricated staircase, including two stair beams 1, folded plate steps 2, and a rest platform 3. The plate step 2, the platform section 12 supports the rest platform 3, the folding plate step 2 is supported on the inclined beam section 11, the rest platform is supported on the platform section 12, and is outside the two ladder beams 1 Cantilever ends are respectively formed; the two ends of the cast-in-place beam 4 supporting the stair section beam 1 are rested on the shear walls or structural beams at both ends of the stairwell on the protruding ears; the folded-plate step 2 includes a precast concrete ladder Plate 21 and folded plate connector 22, bolts are embedded in the prefabricated concrete ladder plate 21, and the bolts pass through the folded plate connector 22 and are fixed by nuts, so that the precast concrete ladder plate 21 is connected to the folded plate The step beam 1 is connected to the corner end of the folded-plate connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com