A jacket base plate structure and a jacket comprising the bottom base plate structure

A jacket and template technology, applied in infrastructure engineering, underwater structures, buildings, etc., can solve the problems that cannot meet the needs of large-scale drilling and production platforms or central processing platform jacket transportation and launching, and achieve simple construction, Effects of reduced capacity requirements and reduced installation weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

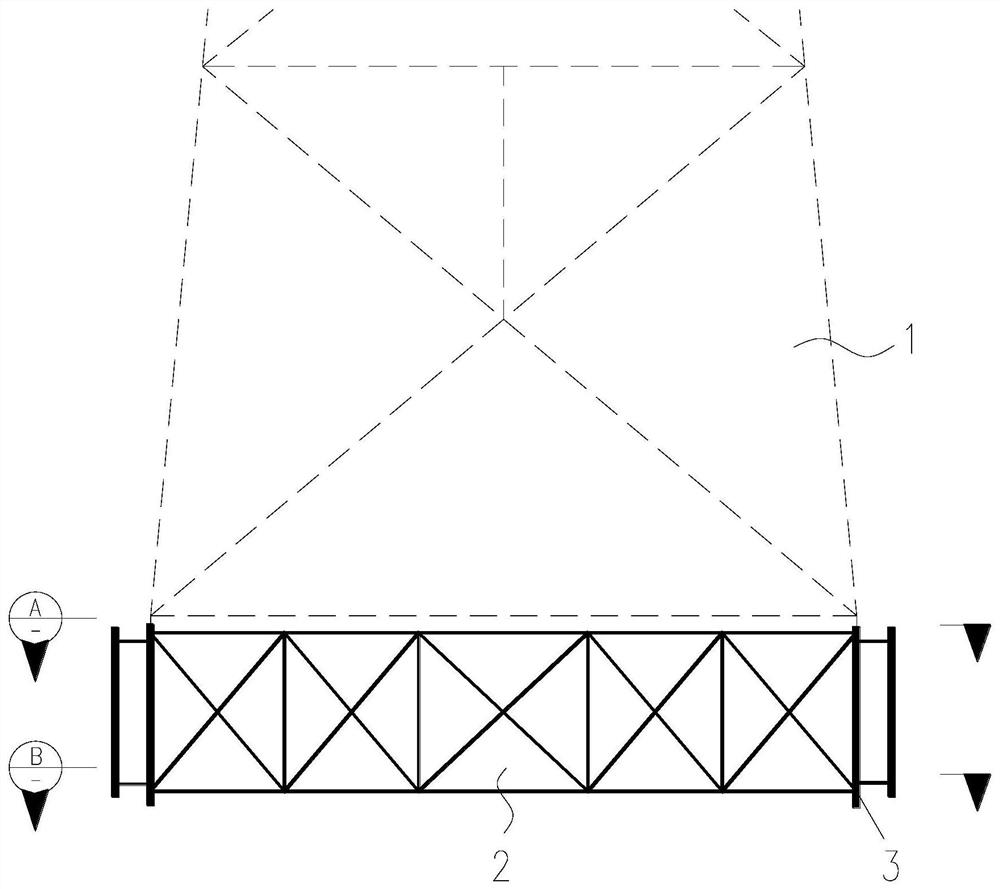

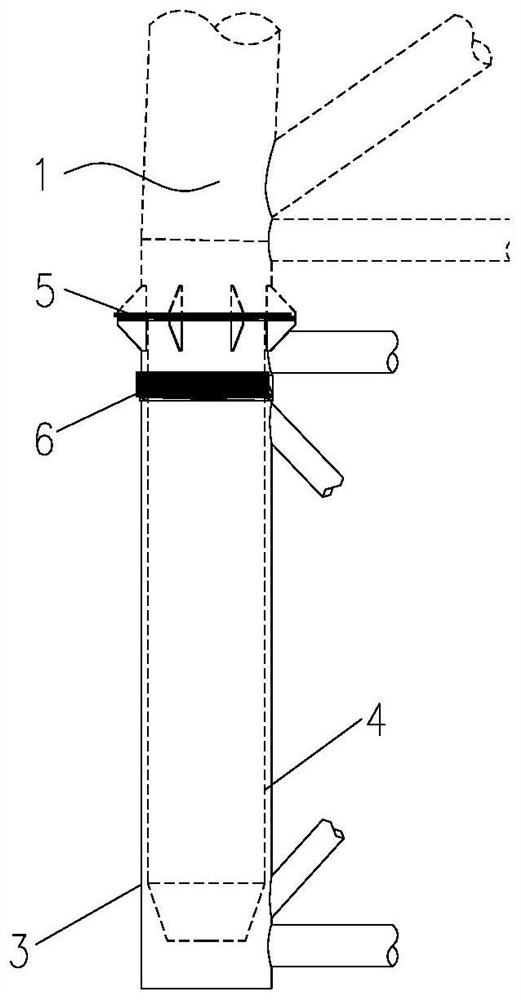

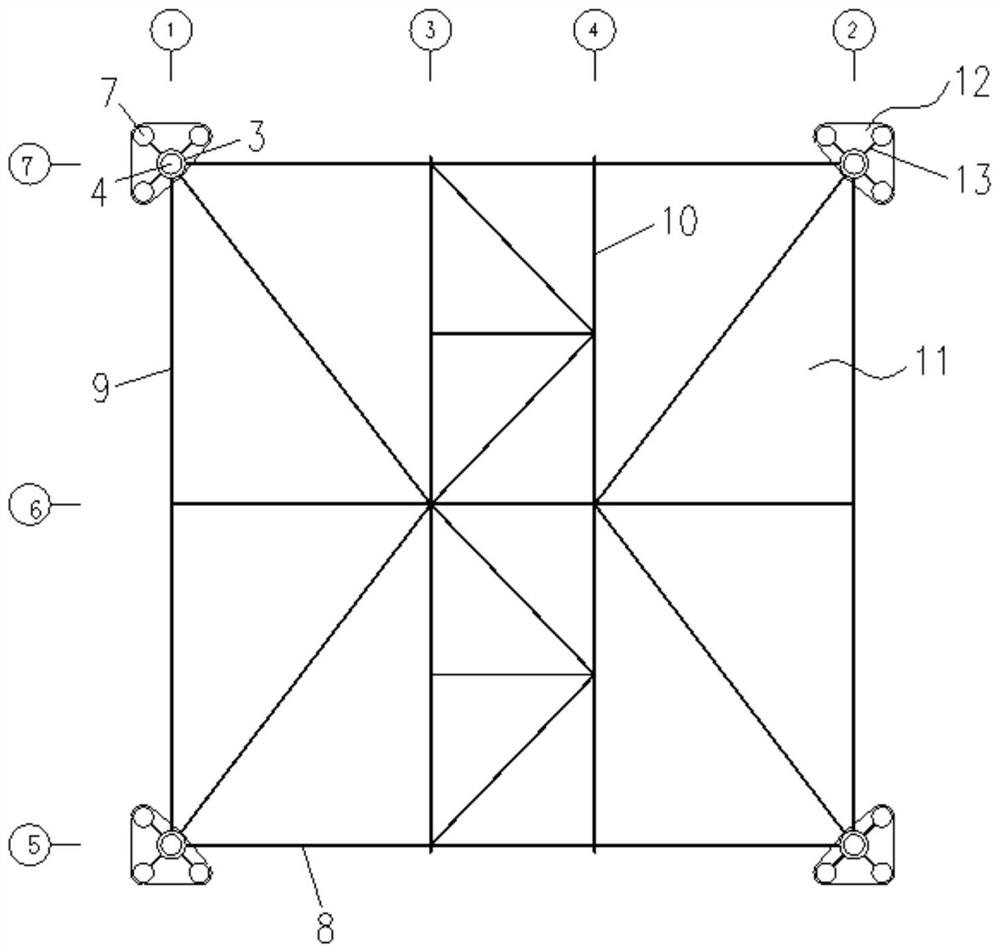

[0039] Such as figure 1 , figure 2 , image 3 As shown, this embodiment provides a base plate structure at the bottom of a large jacket in ultra-deep water, including the following components:

[0040] Base plate main legs 3, several of the base plate main legs 3 are vertically arranged below the jacket main body structure 1 and distributed in a polygonal shape; the top of each of the base plate main legs 3 is provided with a support pad 5, and each of the base plate main legs 3 A pile holder 6 is provided near the top of the main leg 3 of the base plate;

[0041] Pile group sleeves 7, several groups of pile group sleeves 7 are respectively connected to the corresponding main legs 3 of the base plate through connecting plates, and the inside of each group of pile group sleeves 7 is provided with a fixing device driven into the seabed. pile;

[0042]The horizontal façade frame 8 and the first vertical façade frame 9 , the base plate main legs 3 are sequentially and alterna...

Embodiment 2

[0044] Such as figure 1 , figure 2 , image 3 , Figure 7 As shown, this embodiment provides a base plate structure at the bottom of a large jacket in ultra-deep water, including the following components:

[0045] Base plate main legs 3, several of the base plate main legs 3 are vertically arranged below the jacket main body structure 1 and distributed in a polygonal shape; the top of each of the base plate main legs 3 is provided with a support pad 5, and each of the base plate main legs 3 A pile holder 6 is provided near the top of the main leg 3 of the base plate;

[0046] Pile group sleeves 7, several groups of pile group sleeves 7 are respectively connected to the corresponding main legs 3 of the base plate through connecting plates, and the inside of each group of pile group sleeves 7 is provided with a fixing device driven into the seabed. pile;

[0047] The horizontal façade frame 8 and the first vertical façade frame 9 , the base plate main legs 3 are sequential...

Embodiment 3

[0052] Such as Figures 1 to 8 As shown, this embodiment provides a base plate structure at the bottom of a large jacket in ultra-deep water, including the following components:

[0053] Base plate main legs 3, several of the base plate main legs 3 are vertically arranged below the jacket main body structure 1 and distributed in a polygonal shape; the top of each of the base plate main legs 3 is provided with a support pad 5, and each of the base plate main legs 3 A pile holder 6 is provided near the top of the main leg 3 of the base plate;

[0054] Pile group sleeves 7, several groups of pile group sleeves 7 are respectively connected to the corresponding main legs 3 of the base plate through connecting plates, and the inside of each group of pile group sleeves 7 is provided with a fixing device driven into the seabed. pile;

[0055] The horizontal façade frame 8 and the first vertical façade frame 9 , the base plate main legs 3 are sequentially and alternately connected th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com