Metal sealing structure for end of tubing hanger

A technology of metal sealing and metal sealing ring, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., and can solve problems such as inability to judge, leakage, and different detection pressures of metal seal sealing reliability , to achieve the effect of saving installation and debugging time, facilitating assembly and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

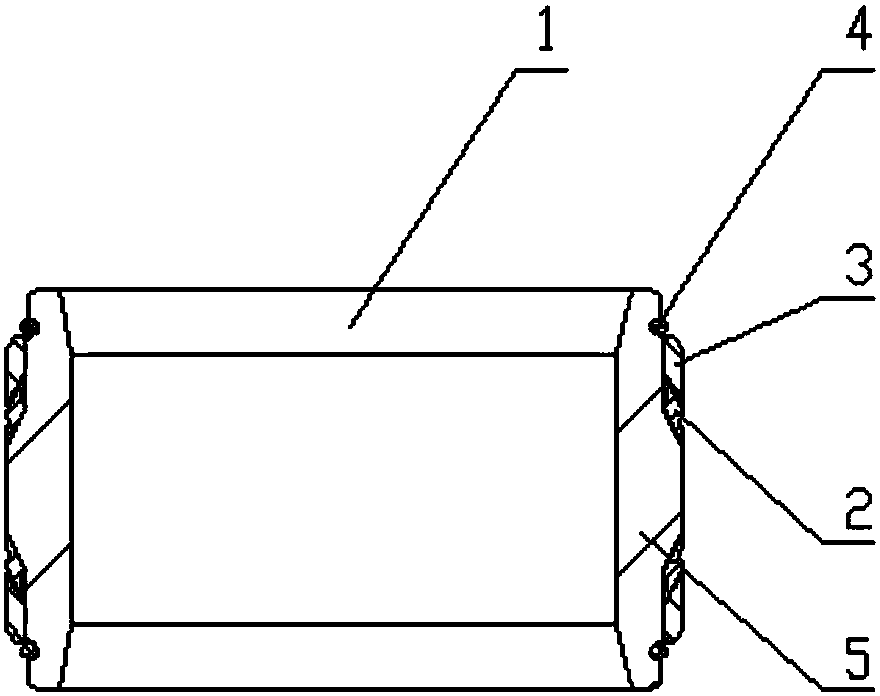

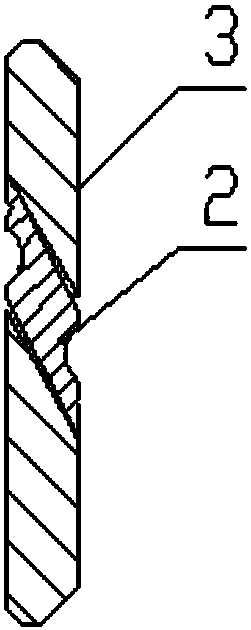

[0024] Such as Figure 1 to Figure 3 As shown, a metal sealing structure for the end of the oil pipe hanger, including a sealing body, the sealing body is composed of a sealing body body 1 and a metal sealing joint 5, and the metal sealing joint 5 will not reduce the strength of the sealed carrier , a circlip 4, half of the circlip 4 is embedded in the outer end surface of the sealing body 1, a support ring 3, the support ring 3 is arranged on the outside of the metal sealing joint 5, a metal sealing ring 2, The metal sealing ring 2 is set in the support ring 3, and the left and right sides of the metal sealing ring 2 are provided with stress relief grooves 6, and one of the stress relief grooves 6 is arranged close to the metal sealing joint 5 On one side of the metal sealing ring 2, there are a pair of deformation grooves 7 on the left and right sides. The sealing between the metal seal at the end of the tubing hanger and the inner surface of the sealed carrier is a metal-to...

Embodiment 2

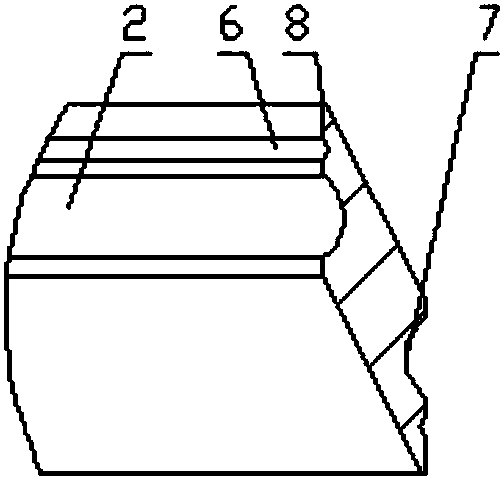

[0027] On the basis of the above embodiments, the metal sealing ring 2 is tubular and its cross section is diamond-shaped, and the metal sealing ring 2 is sealed through the diamond-shaped cross section. The metal sealing ring 2 can withstand 30000Psi working pressure at normal temperature, Both the stress relief groove 6 and the deformation groove 7 are set at the center of the rhombic cross section of the metal seal ring 2 as a central symmetrical point, the deformation groove 7 is arranged inside the stress relief groove 6, and the Both the stress relief groove 6 and the deformation groove 7 are arc grooves, and the diameter of the stress relief groove 6 is smaller than the diameter of the deformation groove 7 .

[0028] The two diagonal corners of the section of the metal sealing ring 2 are contact points, and the contact points are in contact with the sealing body and the sealed carrier respectively, because the hardness of the material used by the metal sealing ring 2 is ...

Embodiment 3

[0030] On the basis of the above embodiments, the sealing body is a mandrel-type sealing body, and the wall thickness of the mandrel-type sealing body is designed to withstand a working pressure of 10,000 Psi, so that the external detection pressure of the metal sealing joint 5 and the internal The detection pressure can be kept consistent, and the metal sealing joint 5 is made of carbon steel, low alloy steel, 300 series stainless steel and corrosion-resistant alloy material and is seamlessly connected with the sealing body 1, so the metal sealing joint 5 can be Used in a wider range of fields, especially for hydrogen sulfide and carbon dioxide corrosion conditions, the metal sealing joint 5 can be used for low temperatures below -60°C and high temperatures above 345°C.

[0031] The outer end surface of the metal seal ring 2 forms an included angle with the contact surface of the support ring 3, and the included angle is 5°-15°, which is determined by the inconsistency of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com