Diameter-adjustable type drill and segmented chambering method

An adjustable drill bit technology, applied to drilling equipment and methods, drill bits, drill pipes, etc., can solve the problems of reducing work efficiency, increasing labor costs, and many connecting components, so as to improve efficiency, reduce labor intensity, and improve structure With stable and durable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

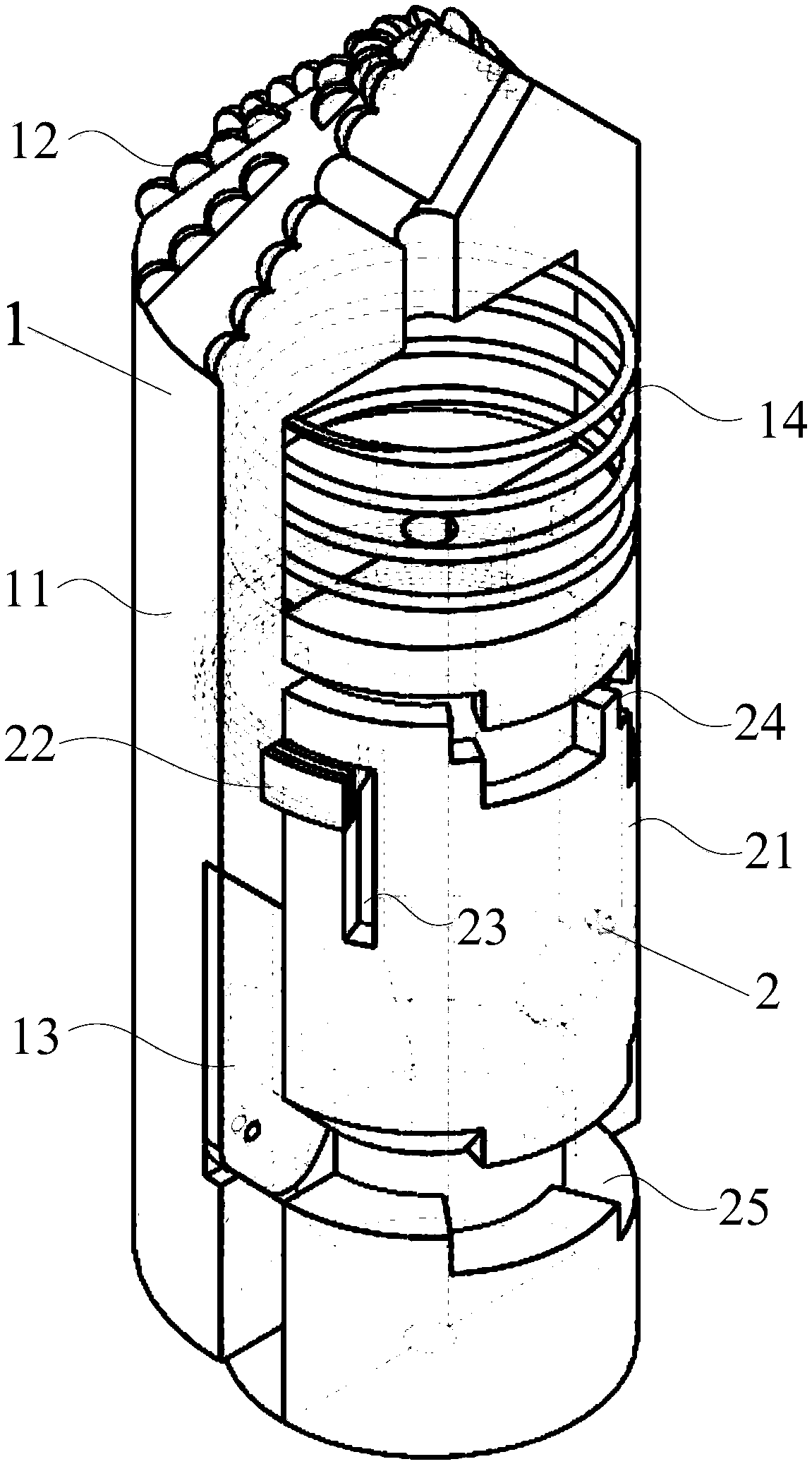

[0021] combine Figure 1 to Figure 4 As shown, the specific implementation of a diameter-adjustable drill bit provided by the present invention is as follows.

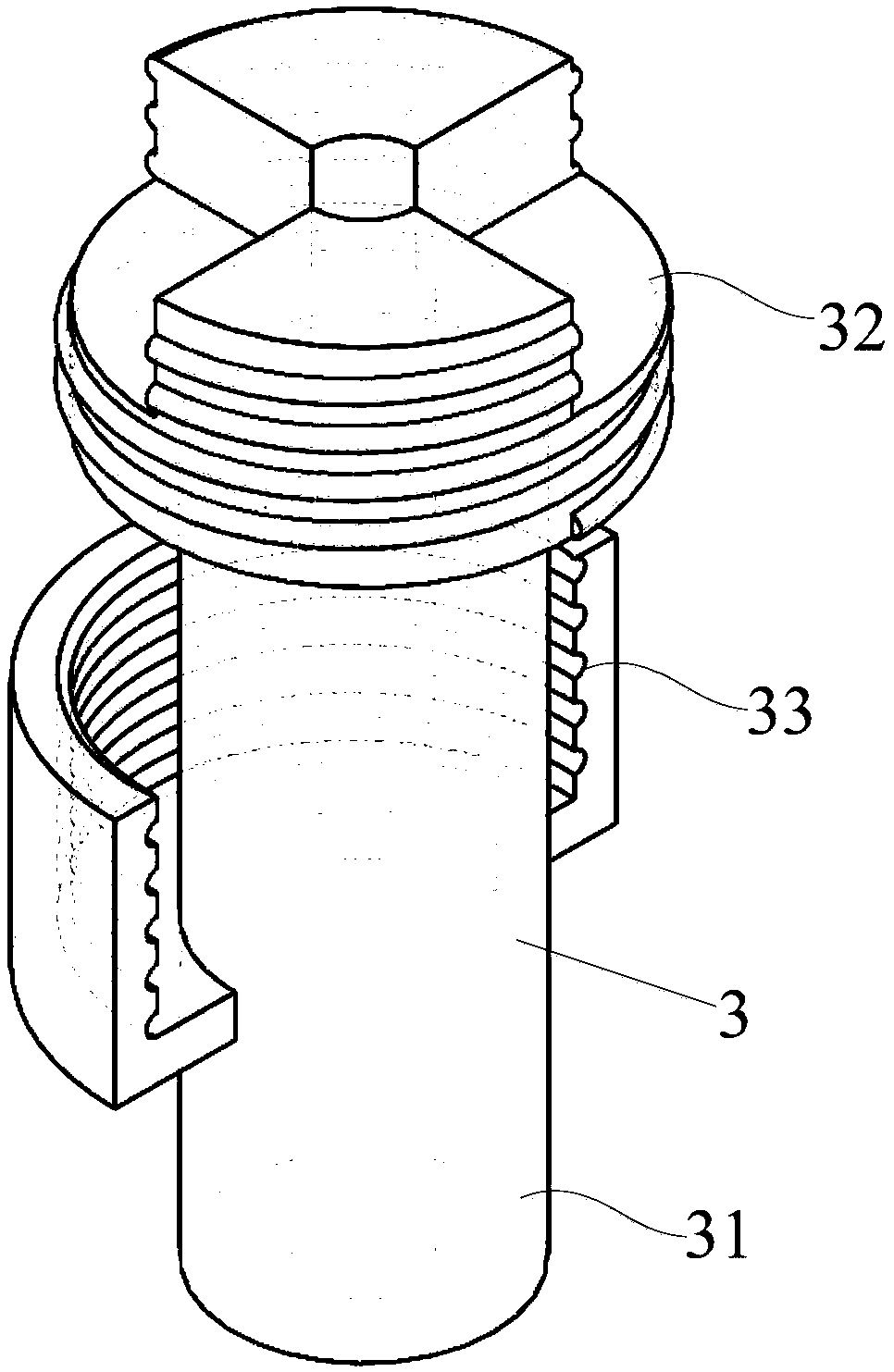

[0022] A drill with adjustable diameter, such as figure 1 As shown, it specifically includes a drilling mechanism 1, an aperture adjustment mechanism 2 and a drill rod mechanism 3. The drilling mechanism 1 and the aperture adjustment structure 2 cooperate with each other. The drill rod mechanism 3 is connected to the drilling machine and the drilling mechanism 1, and the diameter adjustable drill is used Drilling, the drilling diameter of the drill bit can be adjusted by adjusting the drilling direction of the drill rod, so as to achieve the purpose of segmental reaming of the same drilling hole.

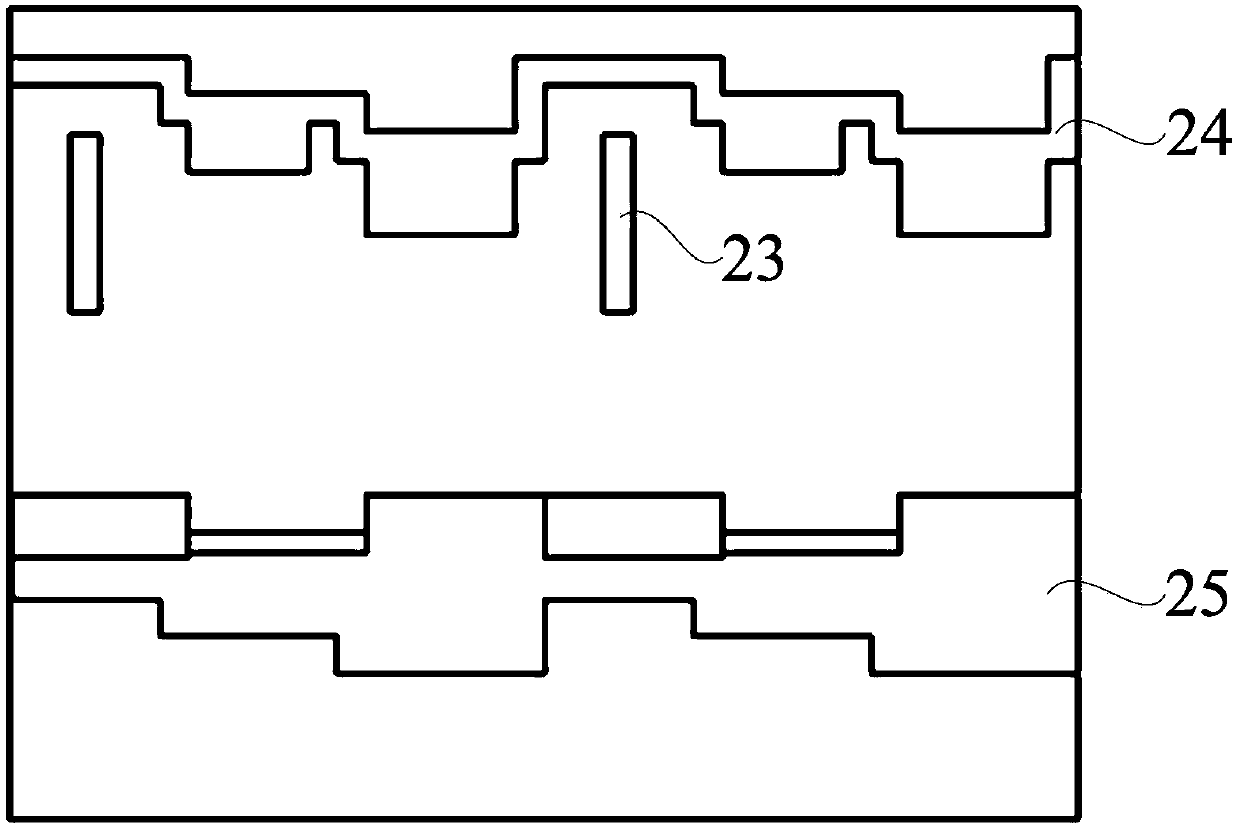

[0023] The drilling mechanism 1 comprises an outer drill cylinder 11, a drilling blade 12, a reaming blade 13 and a spring 14, and the drilling blade 12 is arranged on the front end of the outer drilling cylinder 11, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com