Glove demolding machine

A technology of demoulding machine and glove machine, which is applied in the direction of coating, etc., can solve the problems of downtime repair, air pressure instability, air nozzle demoulding, and increased maintenance frequency, so as to reduce the frequency of downtime maintenance, eliminate influencing factors, and ensure the operation of the device stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical scheme of the present invention is described in detail below in conjunction with the embodiment shown in the accompanying drawings:

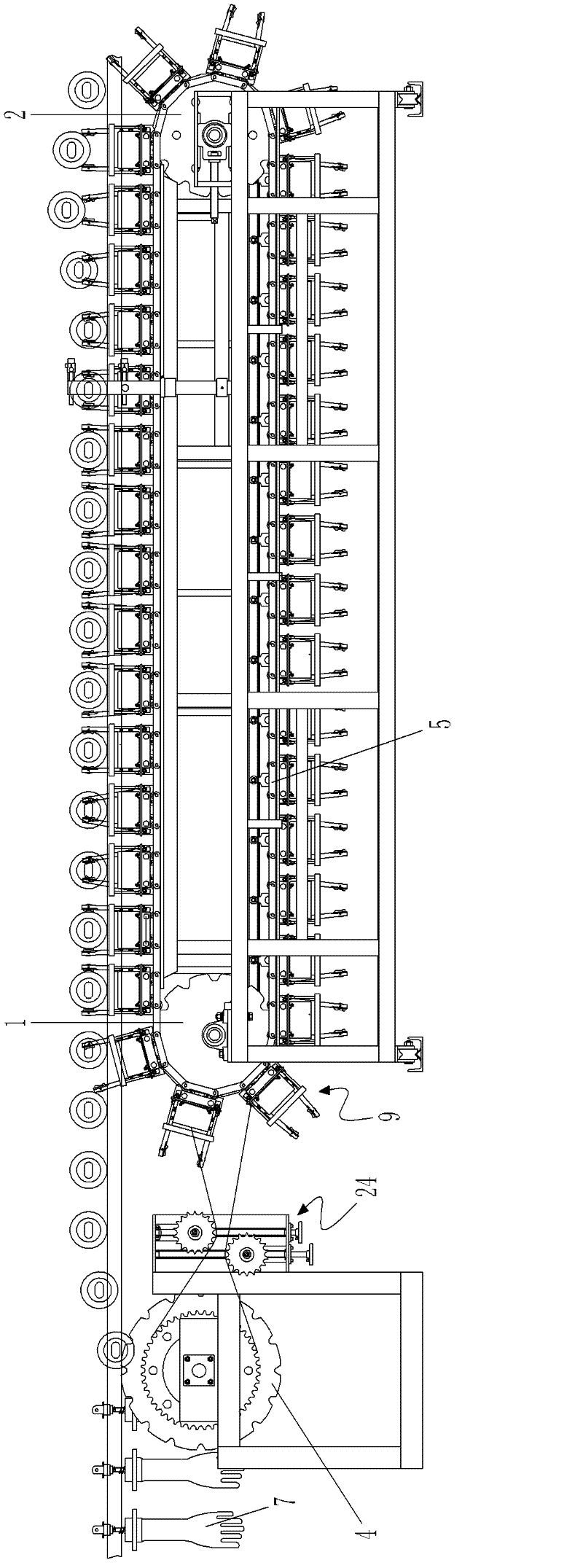

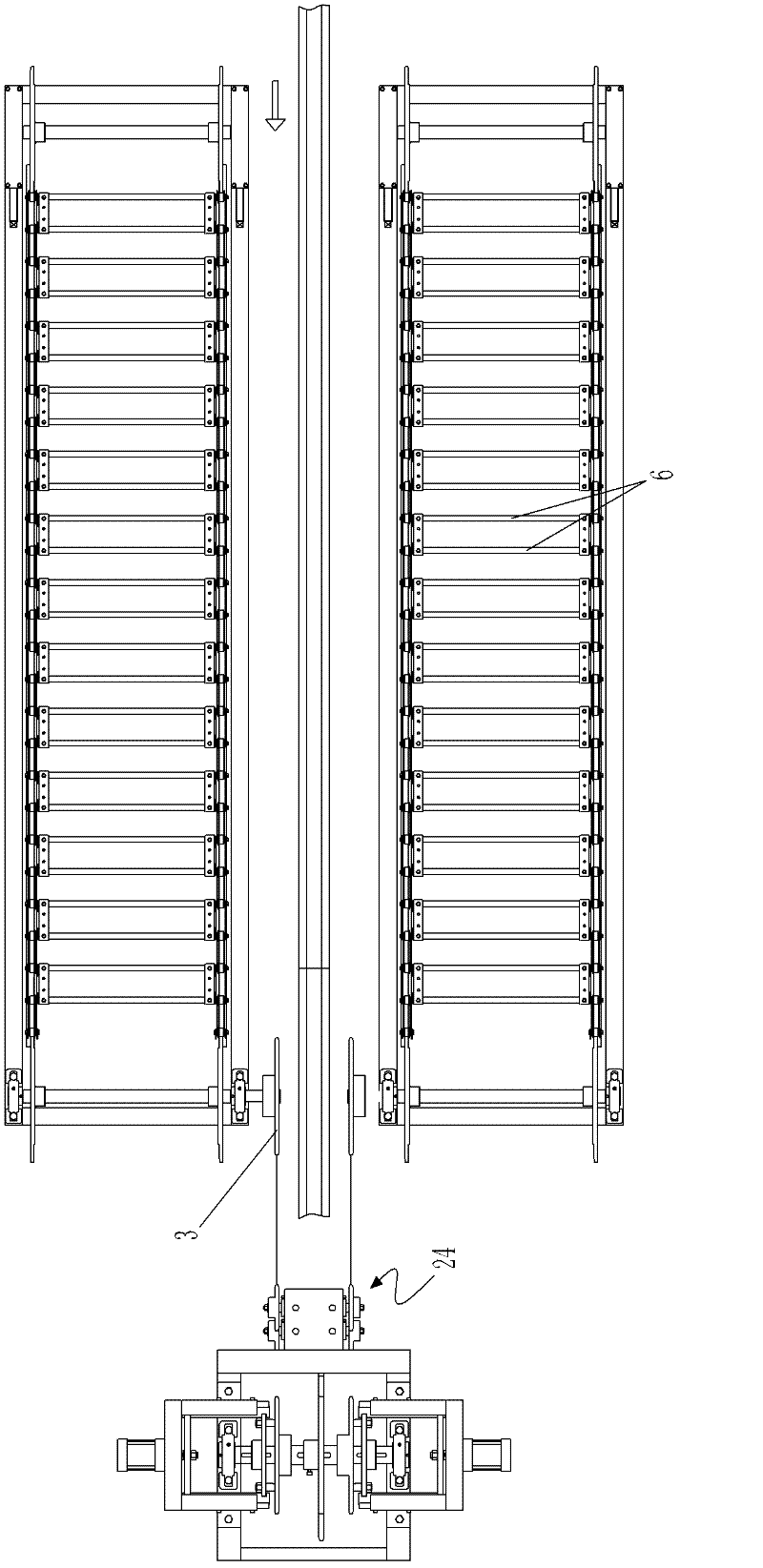

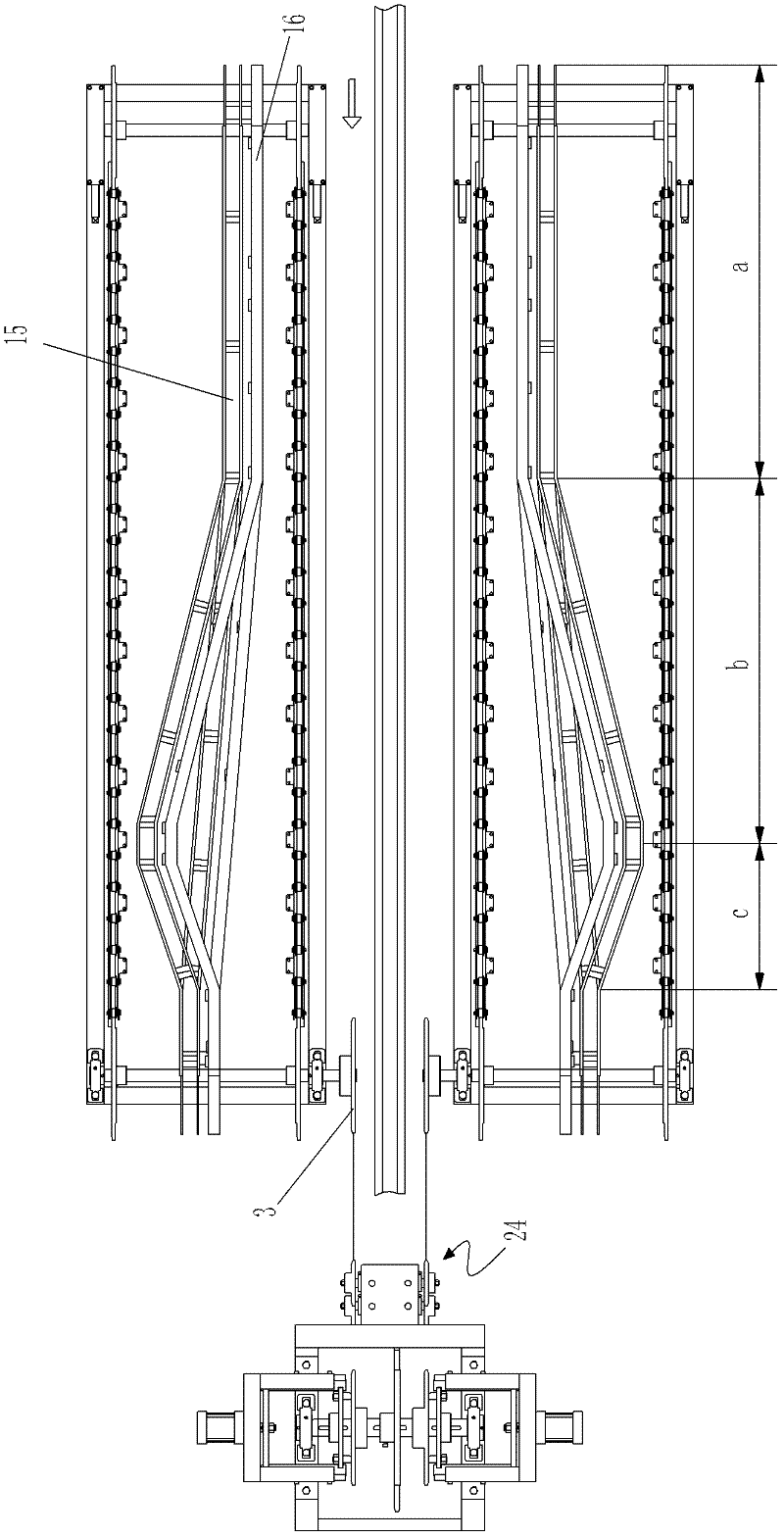

[0026] as attached figure 1 , attached figure 2 and attached image 3 As shown, the glove demoulding machine of the present invention includes a drive unit, a demoulding unit, a guide unit and an edge blowing unit, and the drive unit includes a first chain disc pair 1 and a second chain disc that are respectively coaxially installed at both ends of the frame For 2, the driven sprocket 3 arranged on the shaft where the first chain disc pair 1 is located, and the driving sprocket 4 connected in transmission with the driven sprocket 3, the driving sprocket 4 is coaxially installed on the main shaft of the glove machine. The sprocket 4 and the driven sprocket 3 are linked by a transmission chain, and a tensioning mechanism 24 is added, and the corresponding chain disks on the same side of the first chain disk pair 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com