Contact piece of plate link chain for conical disc winding contact part driving device and plate link chain

A transmission device, the technology of flat chain, applied in the field of flat chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

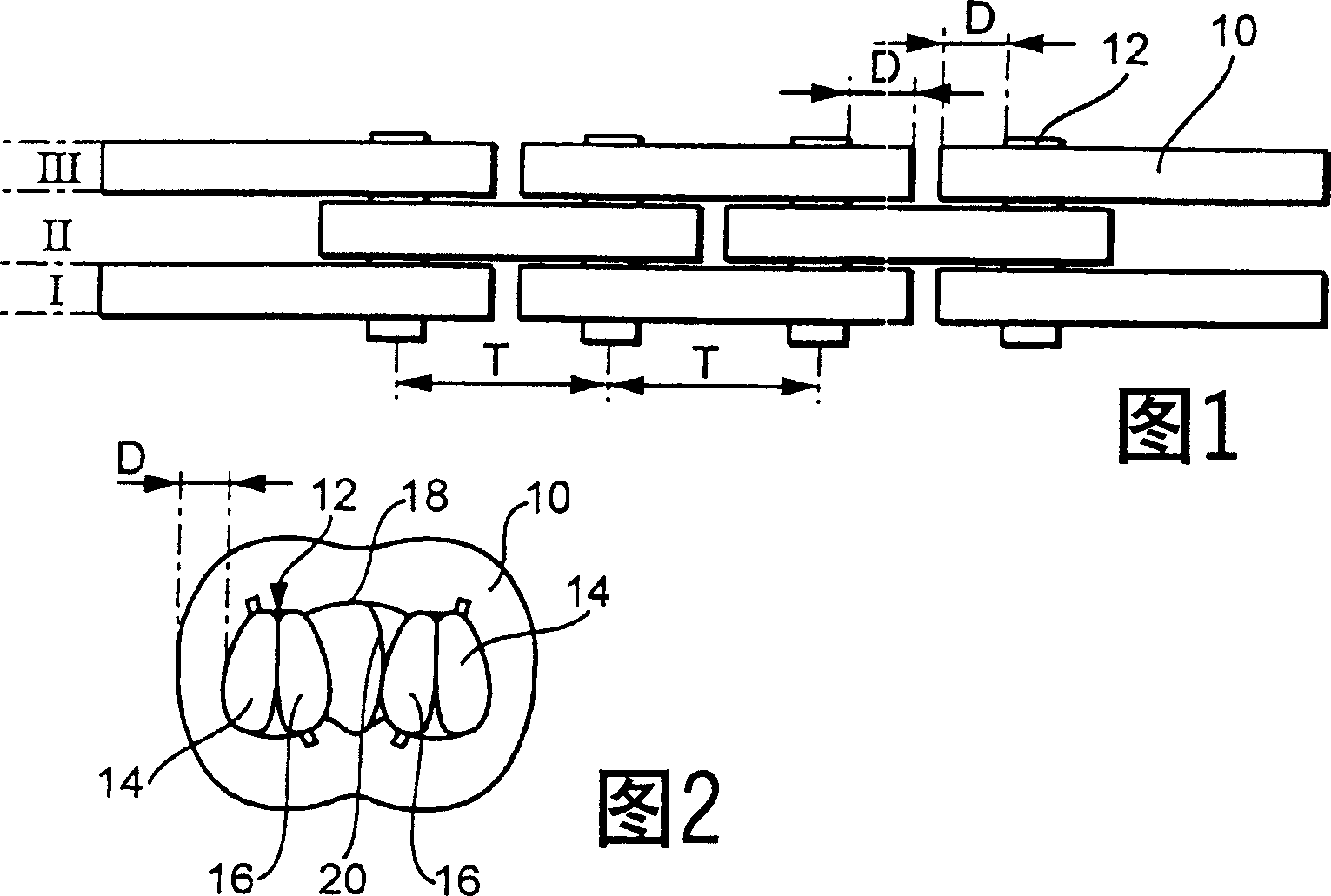

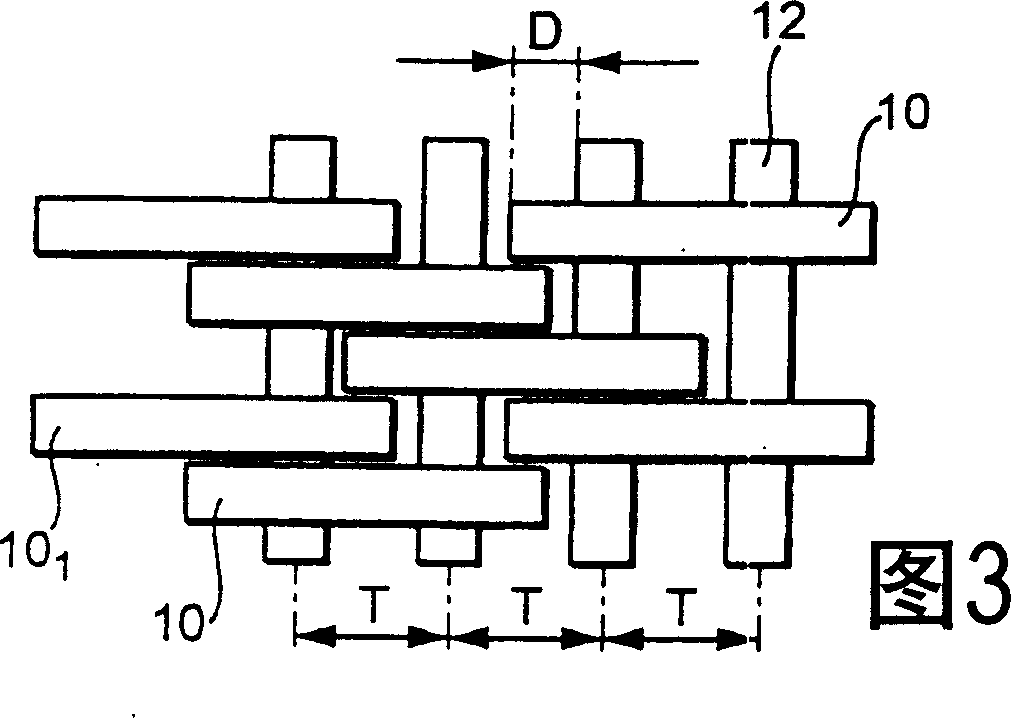

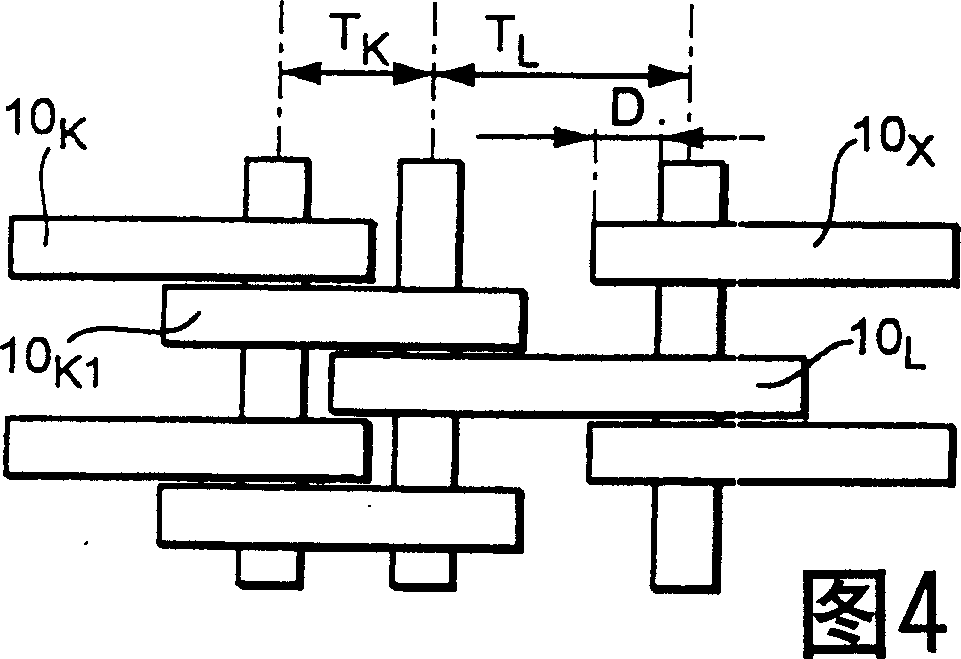

[0031] Figure 6 shows a side view of the tabs used to form a flat link chain according to the invention. FIG. 5 shows a top view of a flat link chain assembled from such webs, wherein, for the sake of clarity, the top view of FIG. 5 is shown more simplified and arranged in a grid relative to the top views of FIGS. 1 , 3 and 4 .

[0032] According to FIG. 6 , a first web type is formed by a shorting web 10 , which is constructed similarly to the web shown in FIG. 2 . The vertical section thickness of this tab 10 is also D, and its longitudinal hole 18 has a predetermined length L measured along the longitudinal direction of the tab. K . In addition to the short link 10, there is also a long link 20, which differs from the short link 10 in that it has a longer length L L , and the difference is that it is formed with a protrusion 22 having a length F at one end. The lug 20 can be inserted into the flat link chain in two directions, ie with the protrusion 22 pointing to the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com