Chain applicable to low temperature environments and production method thereof

A low-temperature environment and chain technology, which is applied in the direction of metal chains, chain rings, transmission chains, etc., can solve the problems of poor reliability, short service life, and low production efficiency, so as to improve the stress situation, improve the processing technology, and prolong the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

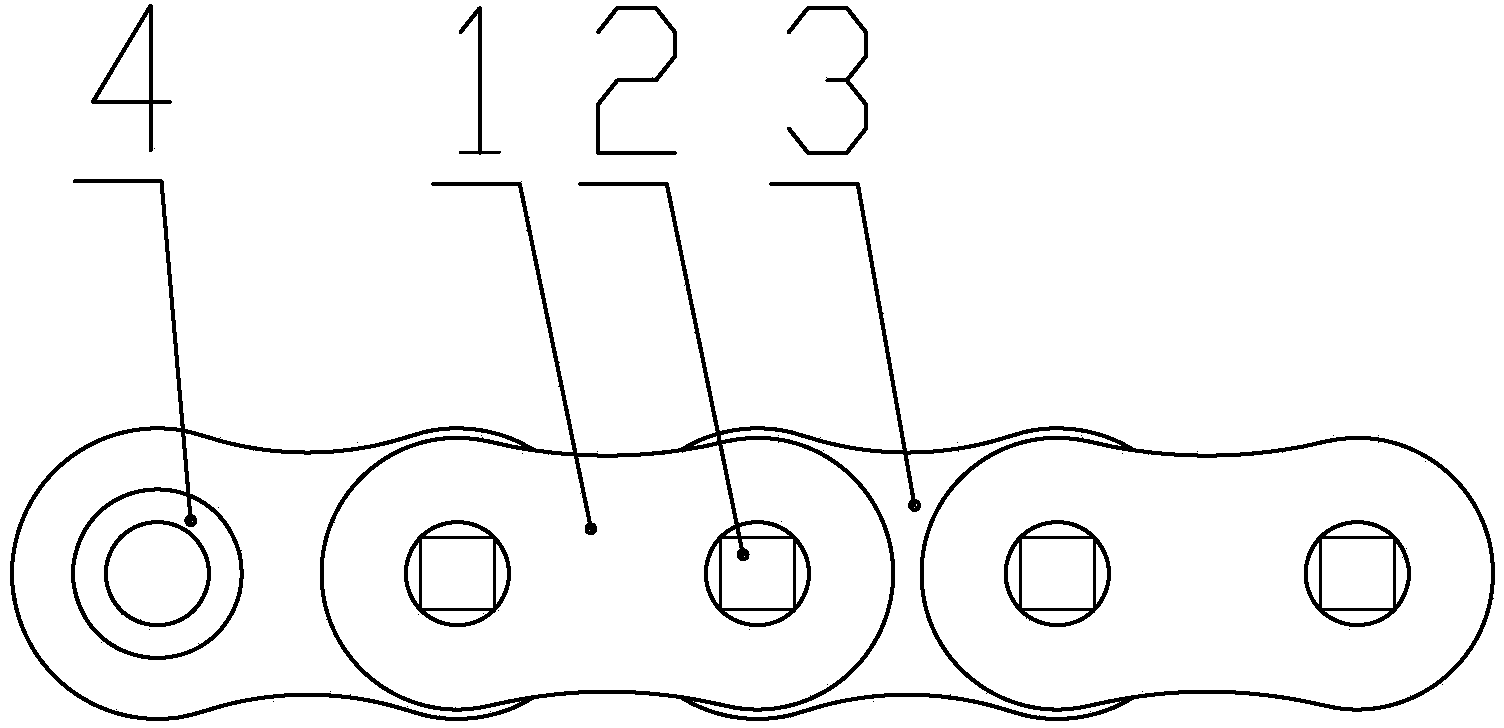

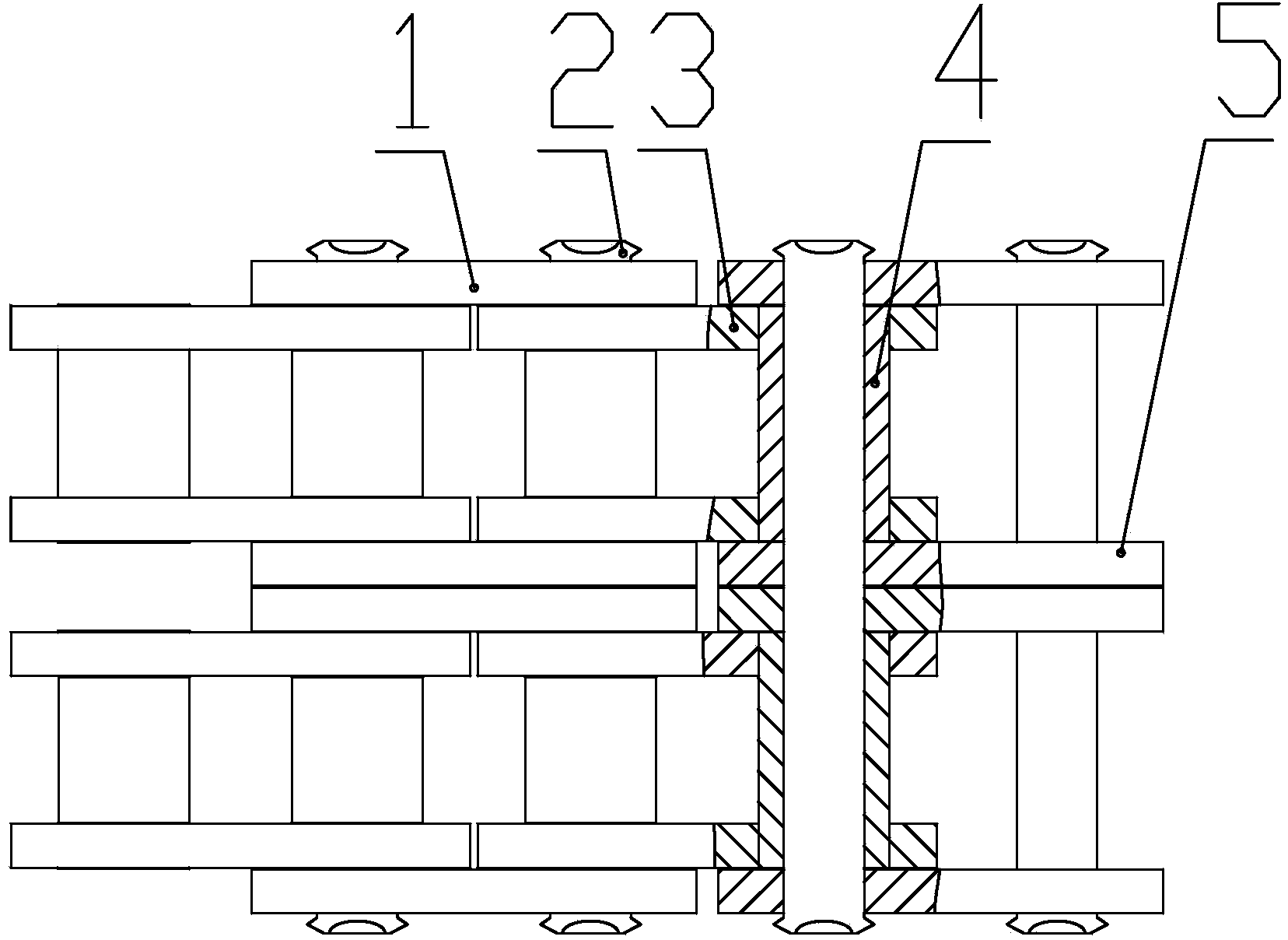

[0013] like figure 1 , figure 2 A chain suitable for low-temperature environments is shown, including an outer chain plate 1, a pin shaft 2, an inner chain plate 3, a sleeve 4 and a middle chain plate 5 made of low-temperature-resistant alloy high-quality steel. The interference fit of chain plate 3 and two sleeves 4 forms an inner chain link, and the interference fit of two middle chain plates 5 and pin shaft 2 forms an outer pin, and a plurality of inner chain links and a plurality of outer pins are assembled in series. The outer chain plates 1 at both ends of the cover are sequentially connected to form a chain; the sleeve 4 is filled with low-temperature grease, and the two ends of the pin shaft 2 respectively pass through the sleeve 4 and the outer chain plate 1 and are locked and fixed by square riveting heads; The outer chain plate 1, the inner chain plate 3 and the middle chain plate 5 all adopt a wide waist structure, and the surface of the pin shaft 2 has a highly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heart hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com