High-strength forged square chain and production method thereof

A high-strength, chain technology, applied in the direction of metal chains, belts/chains/gears, chain rings, etc., can solve the problems of fatigue performance chains not meeting safety performance standards, low tensile performance, high content of alloy elements, etc., to achieve Low cost, high tensile strength, and excellent fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The high-strength forged square chain of the present invention and its preparation method will be further described below in conjunction with specific examples, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

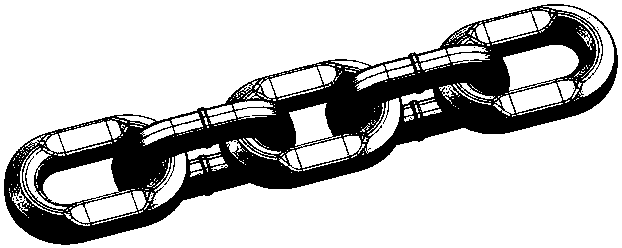

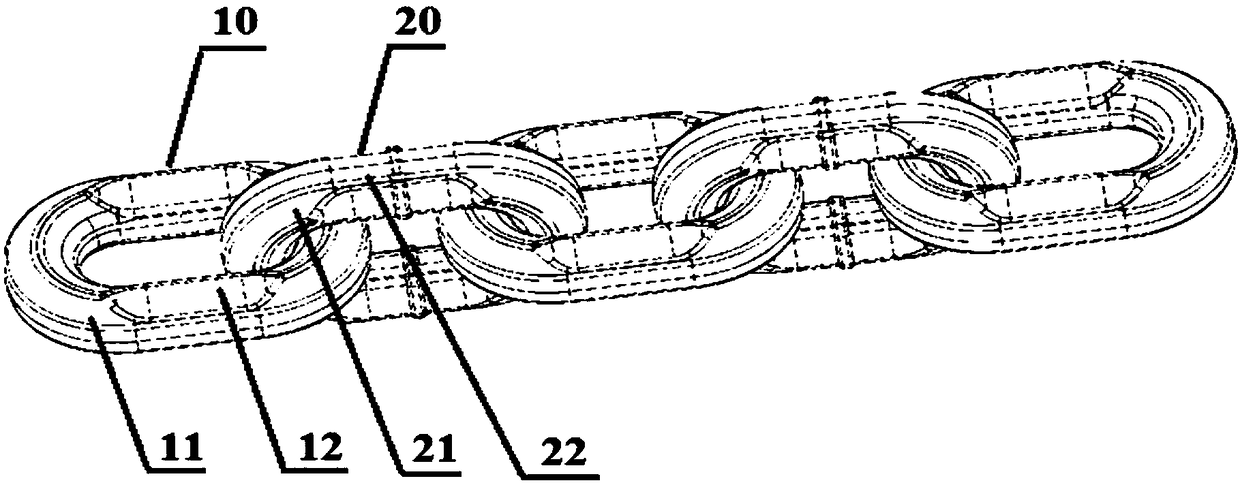

[0023] Such as Figure 1~3 As shown, the high-strength forged square chain of the present invention includes forged rings 10 arranged at intervals, and two forged half-section links 20 are welded to form a long chain structure between adjacent forged rings 10; The arc segment 11 is formed by the straight segment 12 between the arc segments at both ends, and the cross section of the straight segment 12 is a rectangle. The forged half ring 20 is composed of an arc segment 21 and a straight segment 22 located on both sides of the arc segment 21, and the cross section of the straight segment is rectangular. Figure 4 The size of the chain prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com