Automatic lifting mechanism for round metal rod

An automatic lifting and round bar material technology, applied in the direction of metal chains, conveyors, conveyor objects, etc., can solve the problems of difficulty in maintenance and replacement of other parts, large shape of metal ring chains, high price, etc., to reduce labor intensity of workers, The production process is safe and reliable, and the effect of realizing production automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

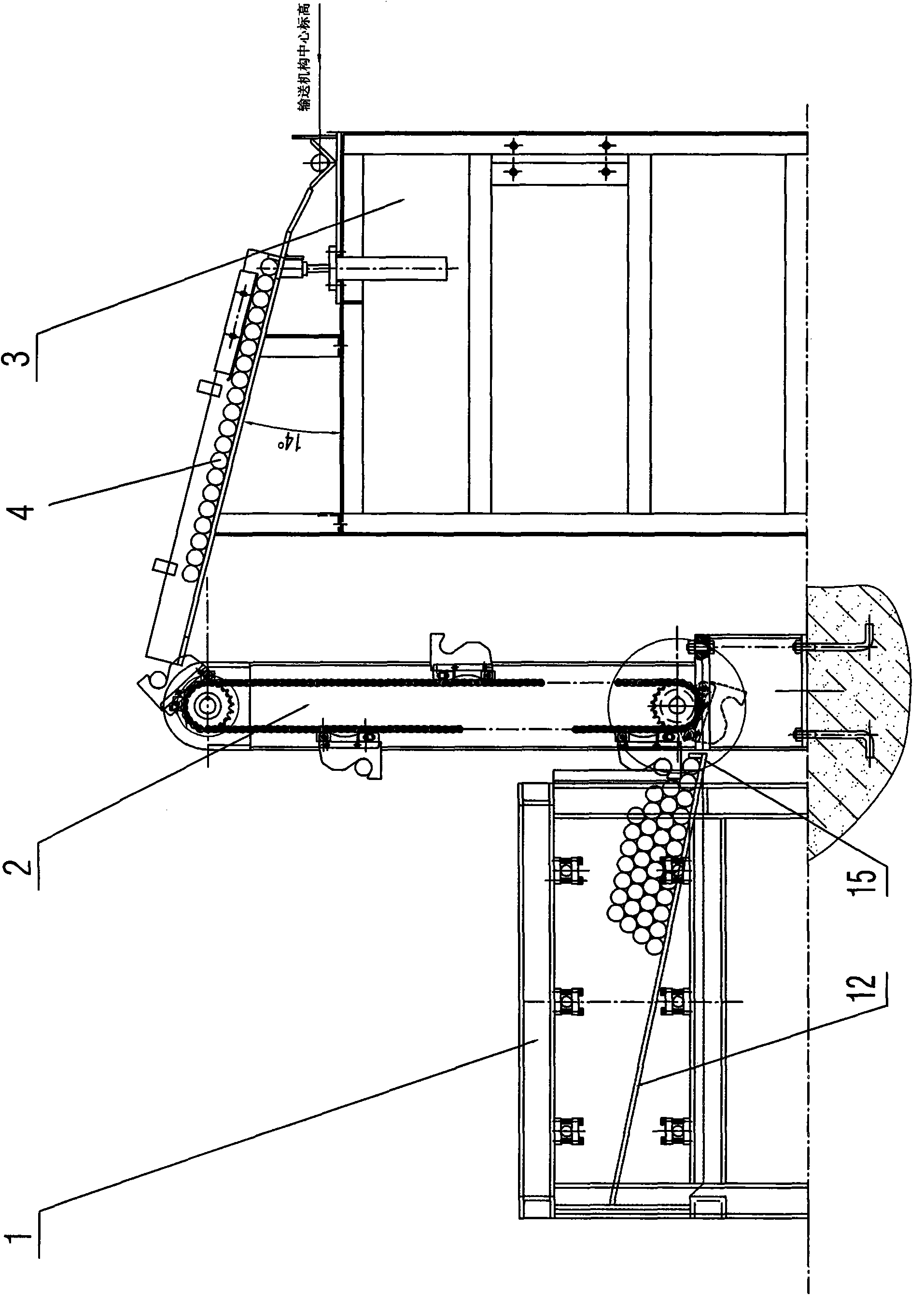

[0018] like figure 1 Shown: The metal round bar material automatic lifting feeding and discharging mechanism is composed of three parts, including: lifting feeding machine; material box; material receiving and discharging frame.

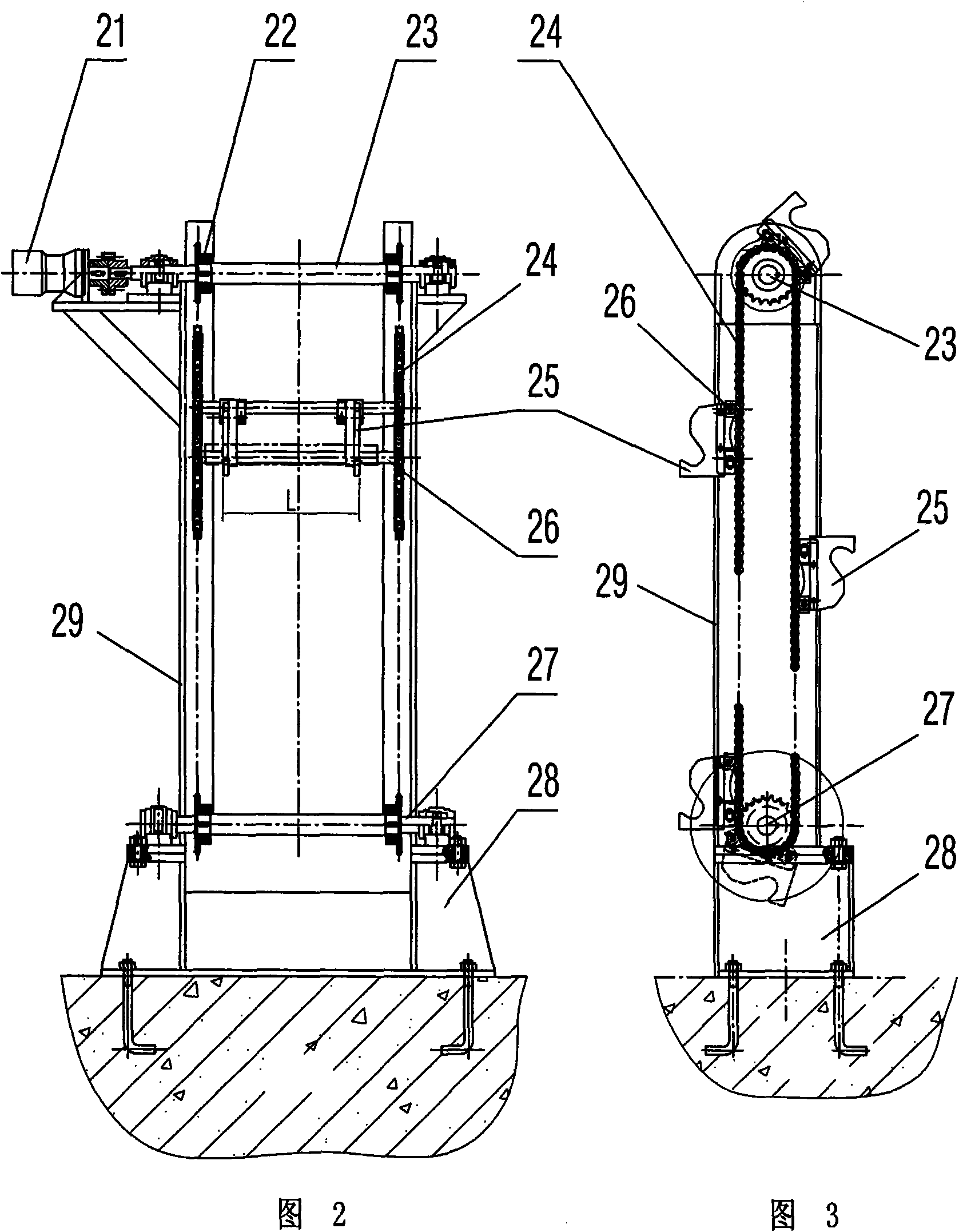

[0019] Lift Loader 2 (see figure 2 ): The lifting feeding machine 2 is equipped with a hydraulic motor 21 as a power source for lifting and feeding; the hydraulic motor 21 is connected with the drive shaft 23 through a coupling, and two sprockets 22 are fixed inside the two fulcrums of the drive shaft 23, Drive chain 24 is housed on the sprocket 22, links to each other with driven shaft 27 by drive chain 24, and this has just formed a pair of drive pairs; Between two drive chains 24, is fixed with 4 pairs of hook fixed shafts 26 by connecting piece, Every pair of hook fixed shaft 26 is fixed with a pair of delivery hook 25, and one end of delivery hook 25 is fastened with a shaft of hook fixed shaft 26, and the other end is then worn on another hoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com