Automatic concatenation knitting-on method and apparatus for metal smith forging circular chain

A round link chain, automatic technology, applied in the direction of metal chains, etc., can solve the problems of difficulty in maintenance and replacement of other parts, difficulty in series knitting, complex structure, etc., and achieve mechanical properties without damage, stable product quality, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

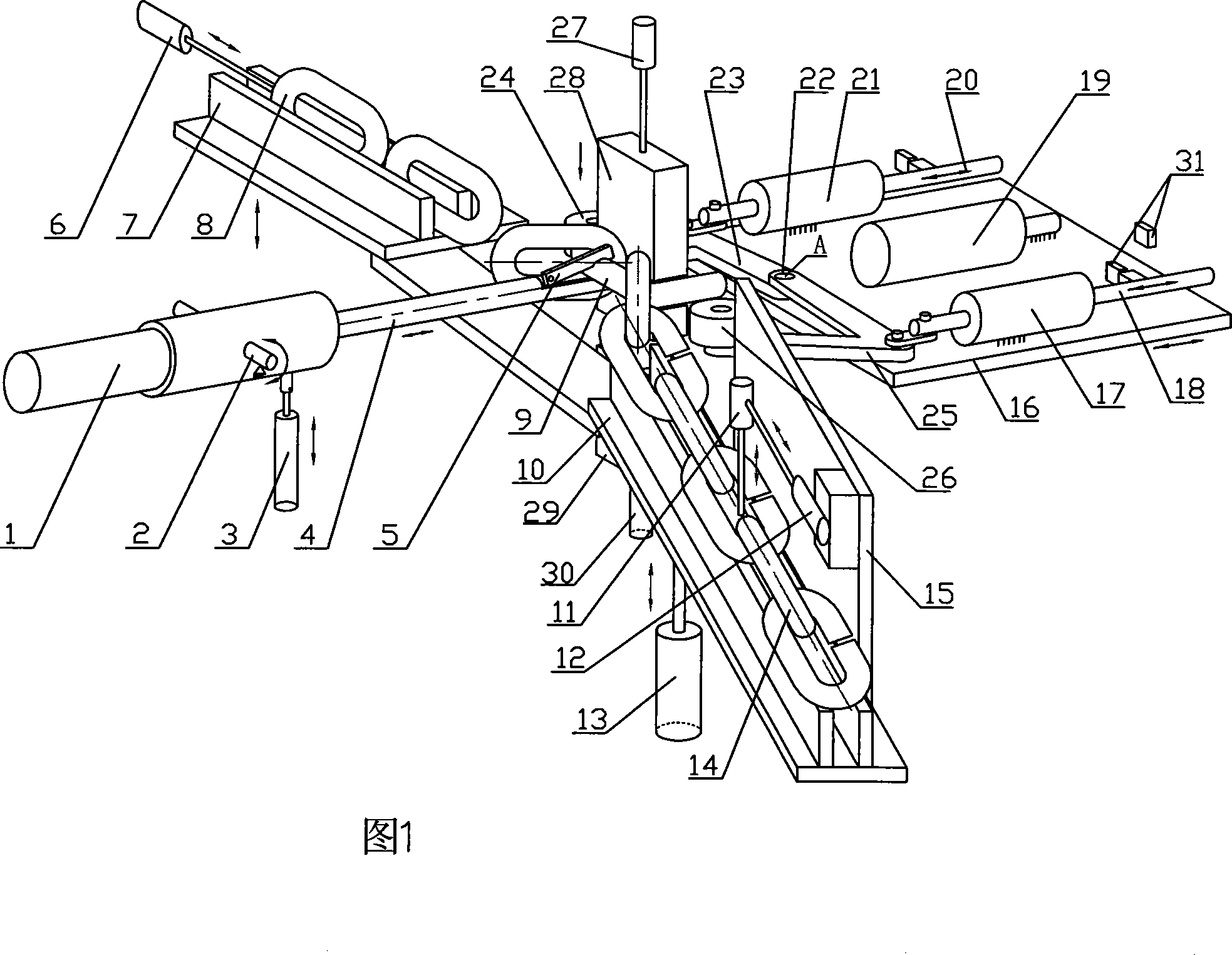

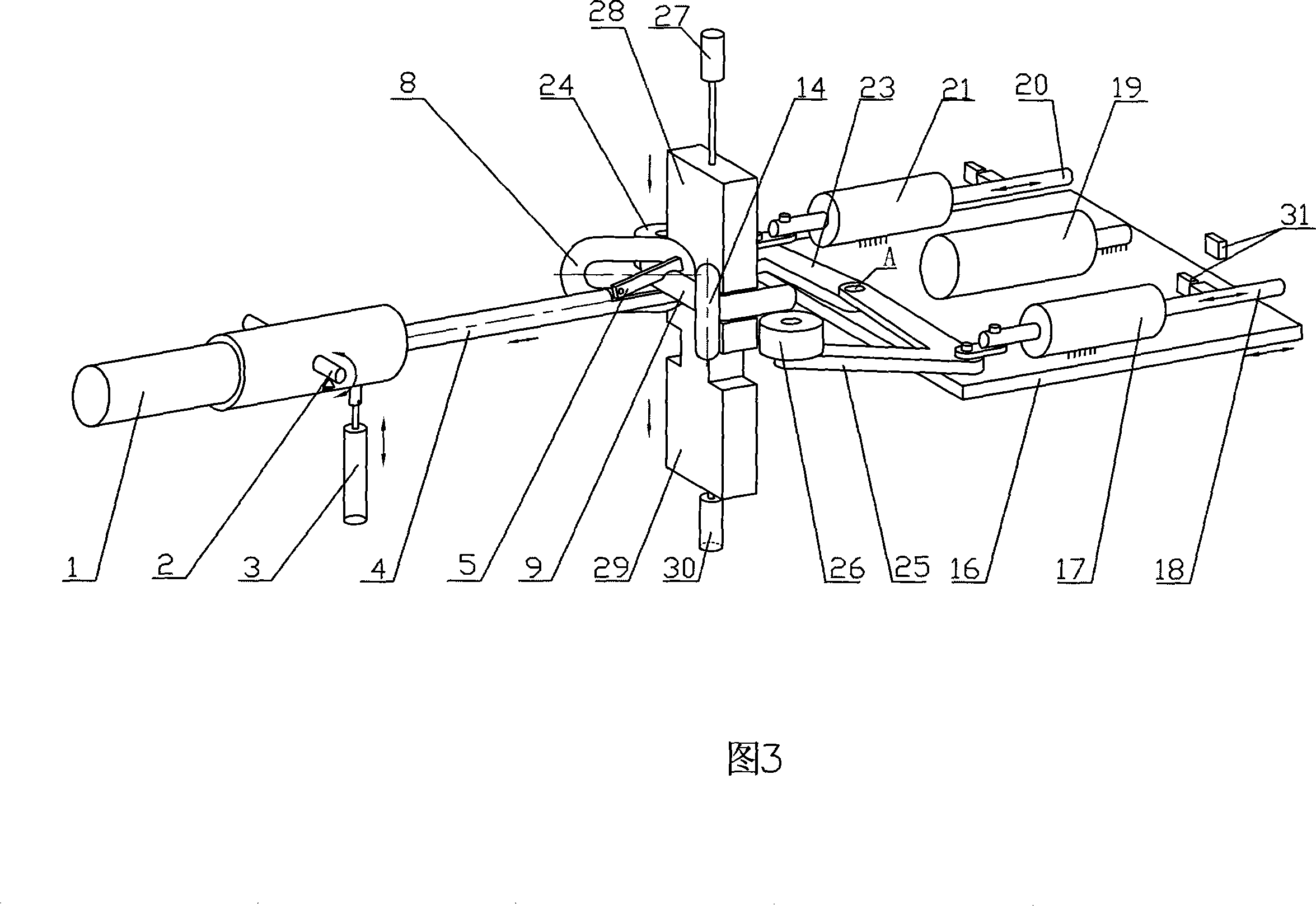

[0048] As shown in Figure 1: the metal forging round link chain automatic series knitting device consists of four parts. Including: manipulator; bending chain mechanism; conveyor chain inlet and outlet trough mechanism; mandrel mechanism.

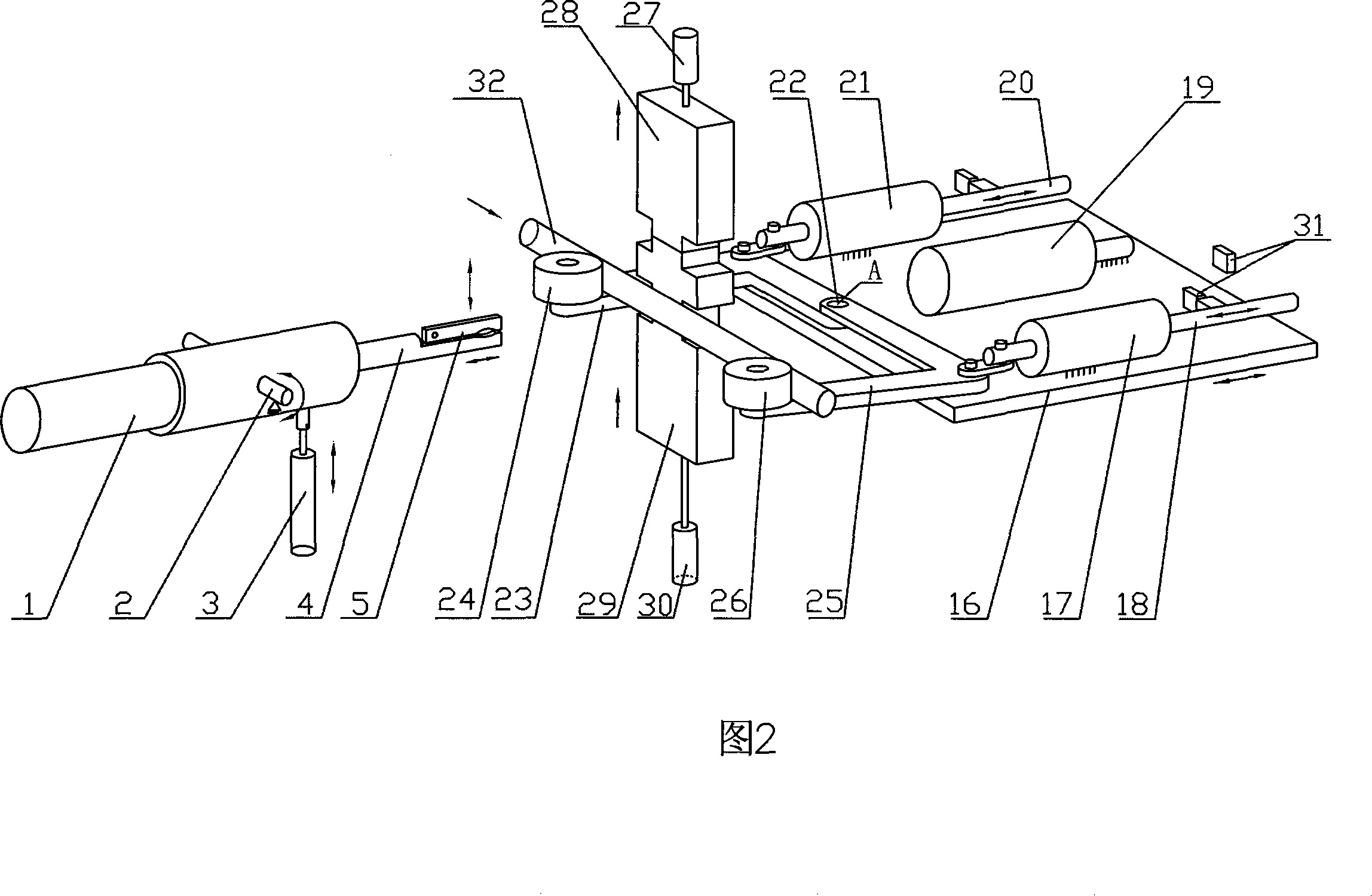

[0049] The manipulator is shown in Fig. 2: the manipulator is equipped with two mechanical fingers 5, which are used to clamp and pick and place workpieces (ie bent ring bars, U-shaped rings, chain links). The manipulator is mainly composed of a serial oil cylinder 1, a clamping and releasing oil cylinder (not shown in the figure), and an up and down swing oil cylinder 3. The forward and backward, clamping and releasing oil cylinders are series oil cylinders 1, and the swing oil cylinders 3 are hingedly connected with the series oil cylinders 1 bottom.

[0050] The manipulator can move forward and backward. Its action is finished by serial oil cylinder 1. Manipulator advances to clamp or send into U-shaped ring 9, and retreats to get bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com