Material feeding system for granulator

A technology of feeding system and granulator, applied in the direction of extrusion and granulation of raw materials, can solve the problems of high production cost, energy consumption and low efficiency, and achieve the effect of saving energy consumption, reducing production cost and running uniformly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

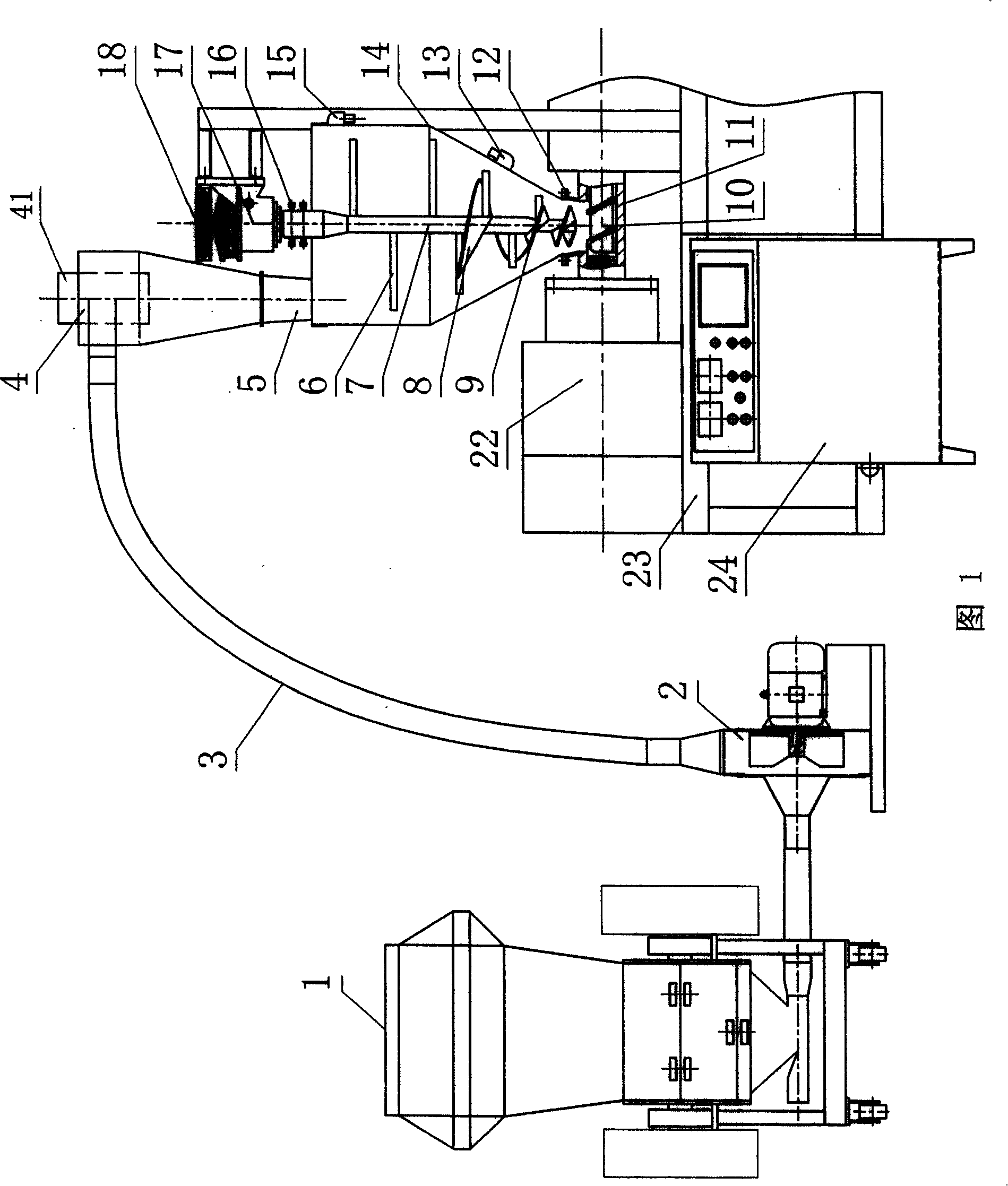

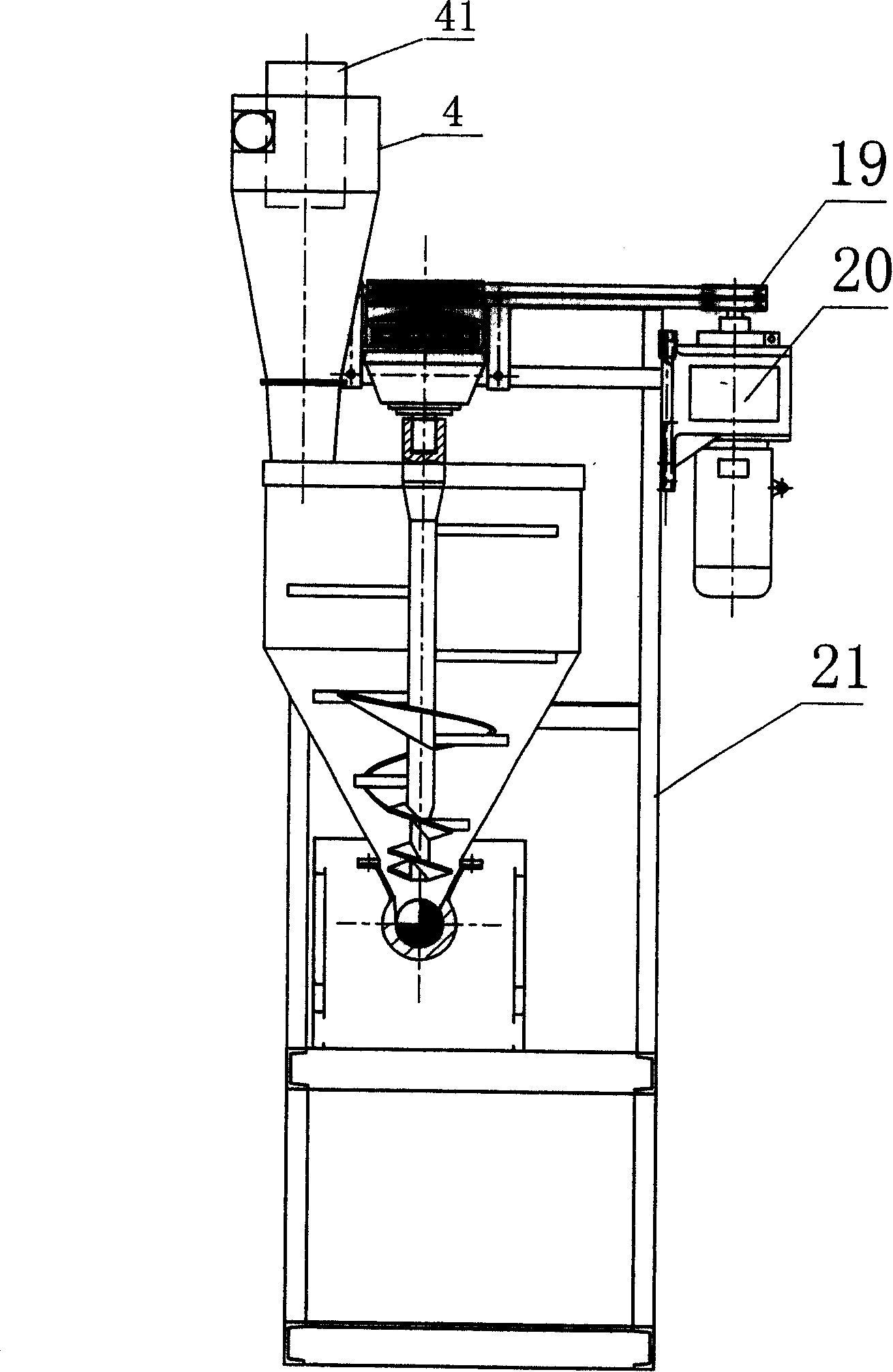

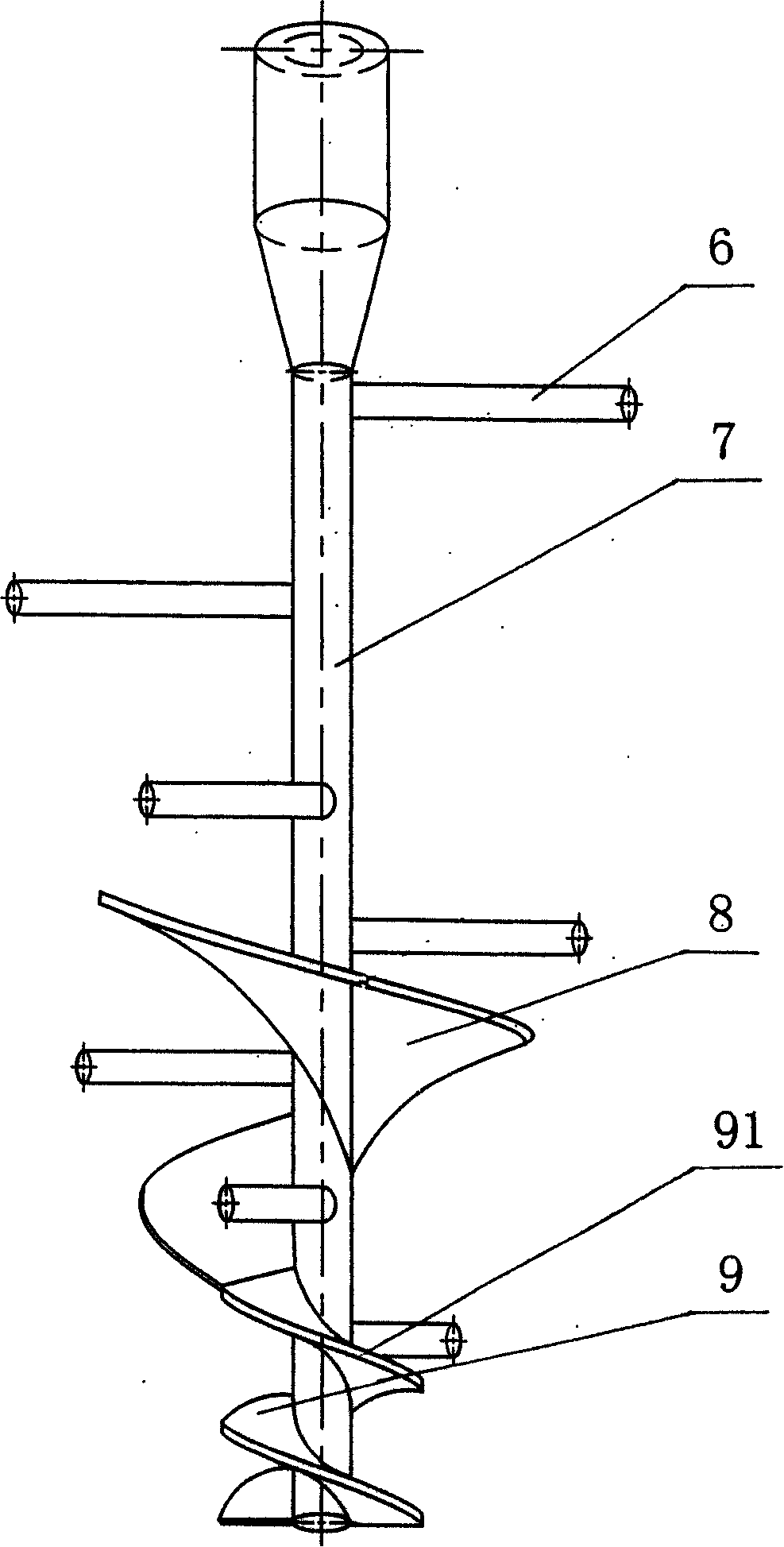

[0021] Figure 1 figure 2 The feeding system of the film, waste silk and flake recycling plastic granulator shown in the figure, the pulverizer 1 enters the feeding barrel 14 through the conveying fan 2, the conveying pipeline 3, and the cyclone separator 4, and the cyclone separator 4 and the feeding barrel Link to each other with connecting flange 5 between 14. The lower end of the feed barrel 14 is connected to the main engine barrel 11 equipped with the main engine screw 10 through the main engine barrel flange 12, and the main engine screw 10 is connected to the main engine gear reduction box 22 installed on the main engine frame 23 and controlled by the electric control box 24 . Feeding bucket 14 is installed on the installation frame 21, and the staving of feeding bucket 14 is equipped with upper positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com