Intellectualized livestock and poultry feeding line capable of realizing precise metering and timed discharge

A kind of livestock and poultry, precise technology, applied in poultry industry, animal husbandry, animal feeding device, etc., can solve the problems of large measurement error, time-consuming labor intensity, weight error, etc., and achieve synchronous feeding and breeding economic benefits The effect of height, growth and health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

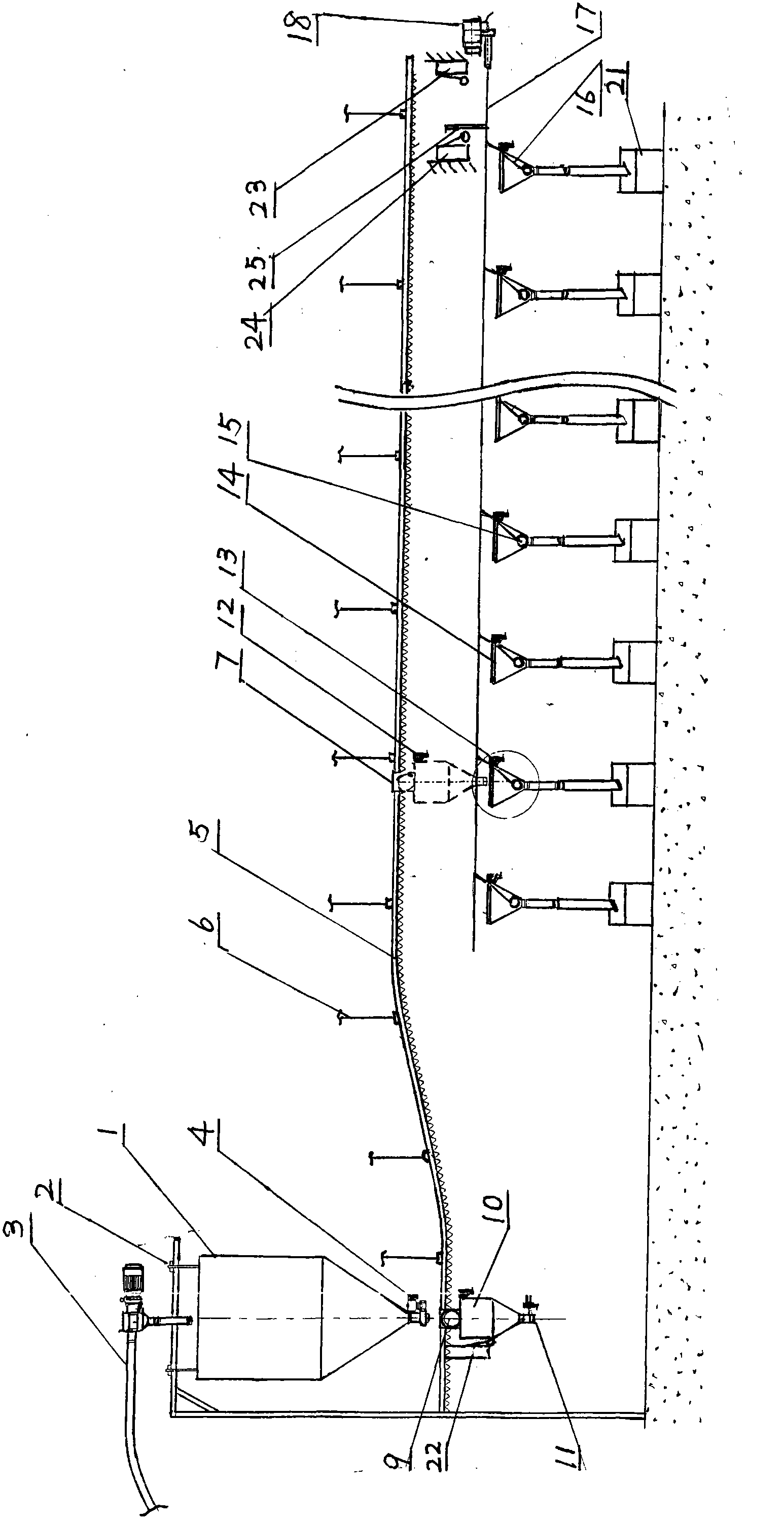

[0017] attached figure 1 It is an embodiment of the present invention, including a material tank, a feeding device, a feeding device, a feeding trough and an electric control device.

[0018] The lower part of the material tank 1 is in an inverted conical shape, and its upper opening corresponds to the discharge port of the feeding pipe 3, and is suspended on the bracket through an electronic scale and a metering sensor 2. The material tank bottom discharge port is provided with a material discharge control solenoid valve 4-SF1. A certain amount of material is added to the material tank, and the set amount of material is placed in the mobile hopper each time, weighed by 'pour and tare', and the sensor sends out a 'measured to' signal.

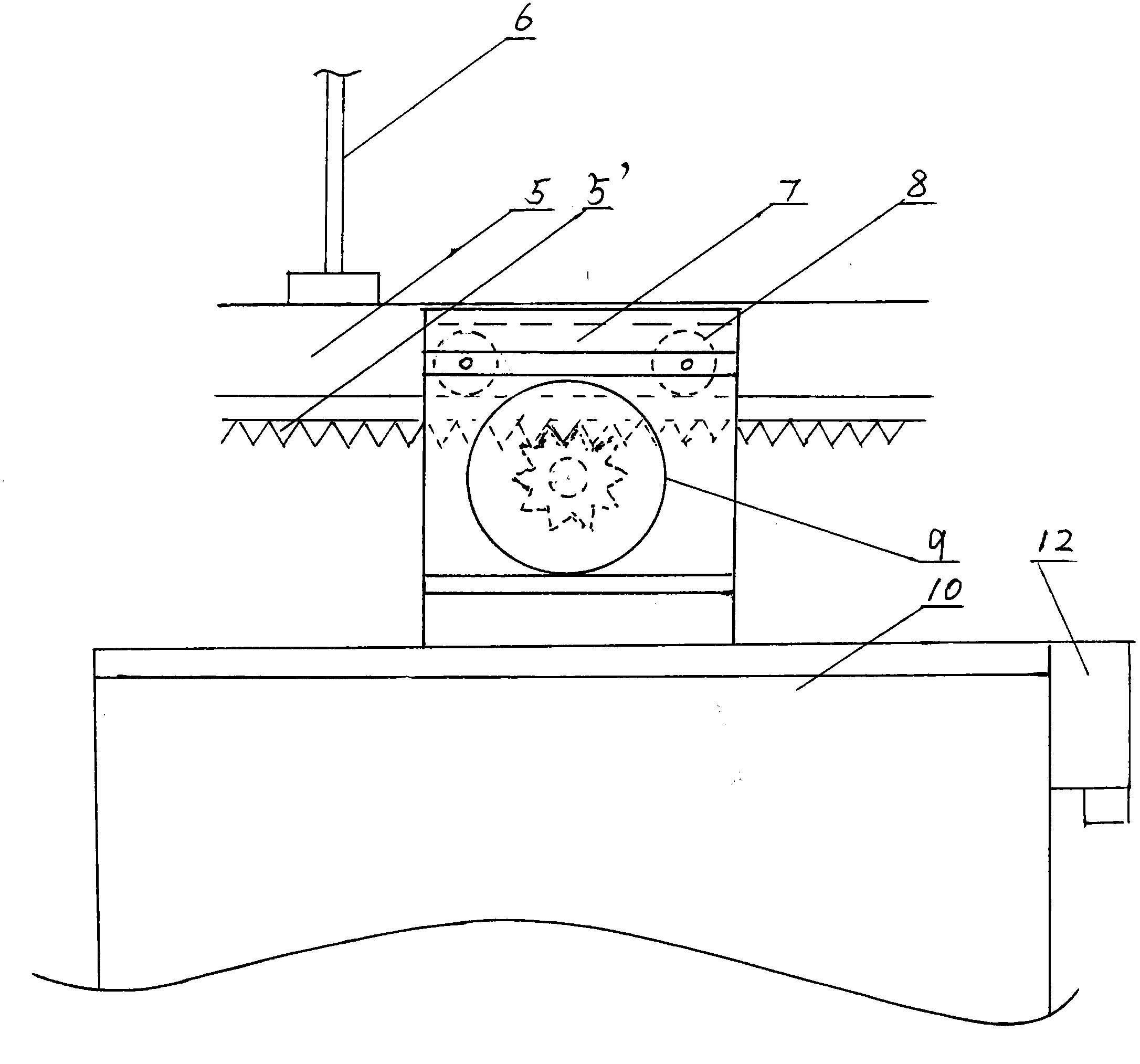

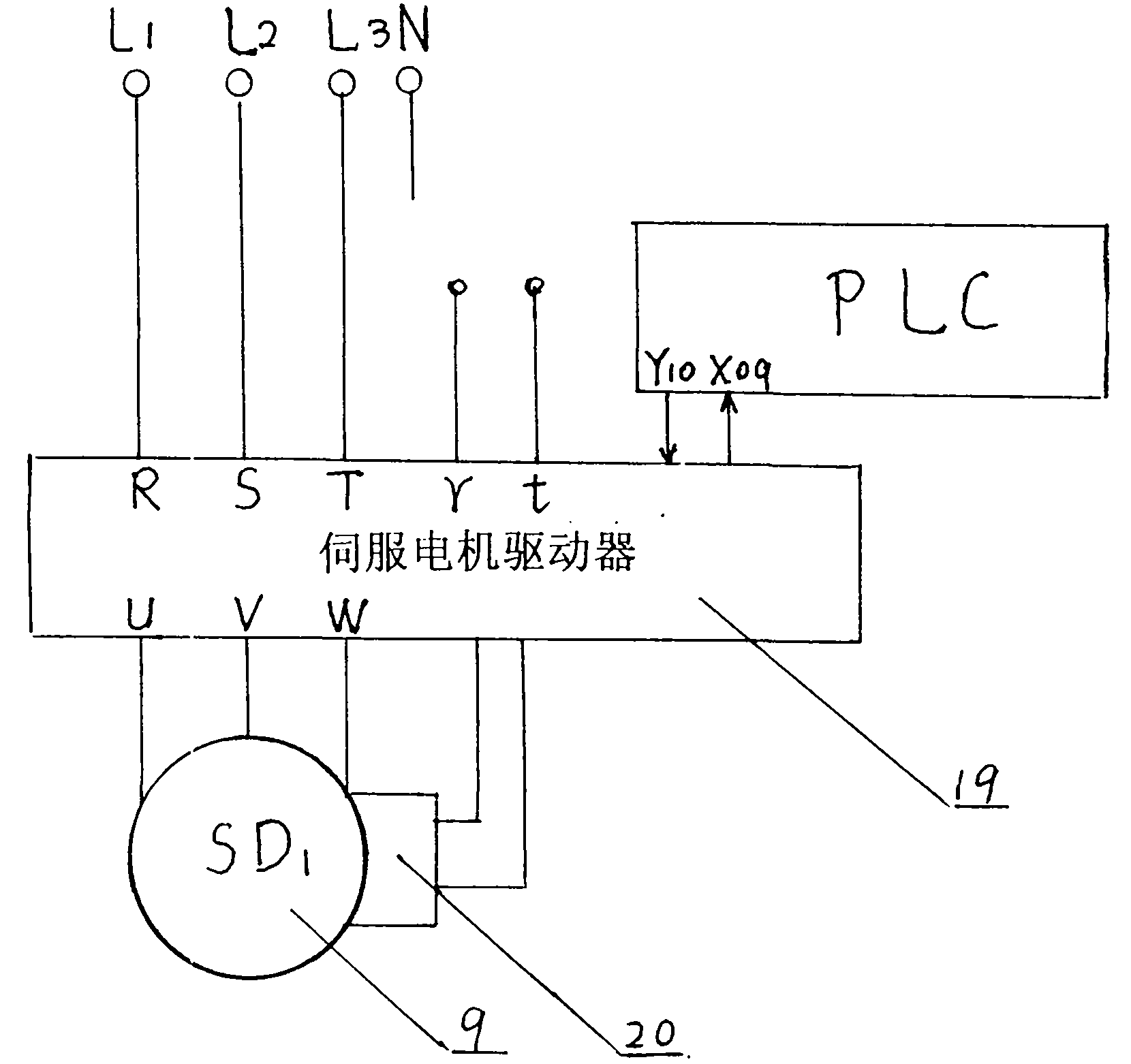

[0019] The material conveying device includes a material conveying track, a moving hopper, a suspension frame, a servo motor, and a searching and positioning device for moving the hopper to find a feeding trough. Above the feeding troughs 21 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com