Strong brine evaporating and crystallizing system

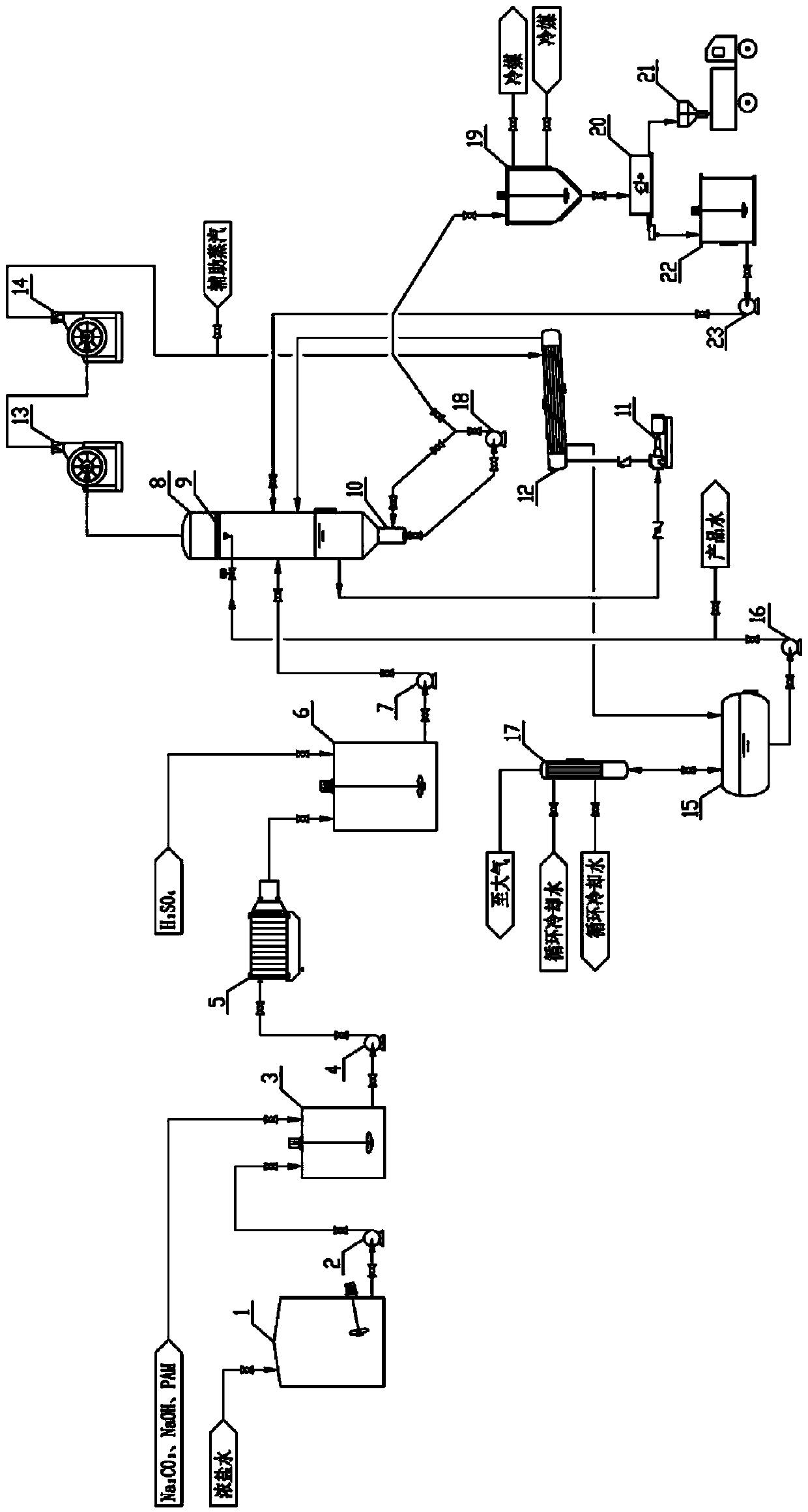

A technology of evaporative crystallization and concentrated brine, which is applied in the directions of water/sewage multi-stage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc. It can solve secondary steam blockage, blockage of heat exchanger tubes and Pipeline, can not run continuously and stably, etc., to reduce energy consumption and avoid blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The system of the present invention is used to process mixed concentrated brine with a TDS concentration of 100-300 g / L.

[0049] The high-concentration mixed brine enters the feed buffer tank 1, when the liquid level in the feed buffer tank 1 reaches 20%, the first agitator starts automatically, and stops automatically when the liquid level is lower than 20%. The concentrated brine in the feed buffer tank 1 is transported to the decalcification-magnesium reaction tank 3 through the first pump 2. When the liquid level of the reaction tank 3 is lower than 10%, the first pump 2 is automatically started to transport the concentrated brine to the reaction tank 3; When the liquid level in the reaction tank 3 reaches 75%, the first pump 2 stops automatically, when the liquid level in the reaction tank 3 reaches 20%, the fifth agitator automatically starts, and automatically stops when the liquid level is lower than 20%.

[0050] When the liquid level in the decalcification an...

Embodiment 2

[0062] The concentrated brine effluent obtained by the mechanical vapor recompression evaporation technology of the seed crystal method is treated by the system of the invention. Among them, Table 1 is the water quality table of the seed crystal method mechanical vapor recompression evaporation technology.

[0063] pH

Ca 2+

Mg 2+

Na +

K +

SO 4 2-

Cl -

F -

4~6

1200

3195

70000

601

1148

180942

26.5

NO 3 -

Br -

B

SiO 2

TDS

TSS

COD

2.6

80

142

307

226016

46180

410

0.7

[0064] Table 1

[0065] The concentrated brine enters the feed buffer tank 1, when the liquid level reaches 20%, the first agitator starts automatically, and stops automatically when the liquid level is lower than 20%. The concentrated brine is transported to the decalcification and magnesium reaction tank 3 through the first pump 2. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com