Concentrated brine evaporation crystallization system

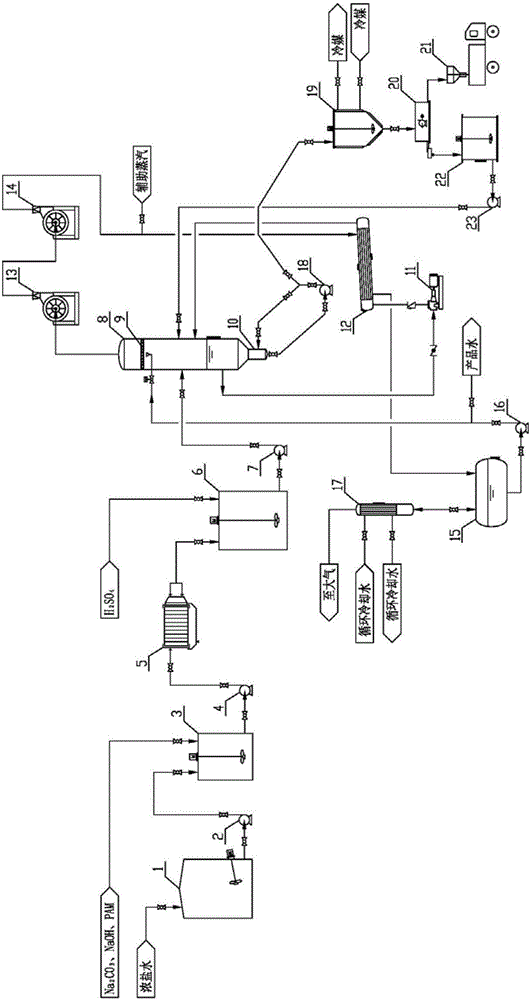

A technology of evaporation crystallization and concentrated brine, which is applied in the directions of water/sewage multi-stage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc. It can solve secondary steam blockage, blockage of heat exchanger tube and Pipeline, can not run continuously and stably, etc., to reduce energy consumption and avoid blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The system of the present invention is used to process mixed concentrated brine with a TDS concentration of 100-300 g / L.

[0049] The high-concentration mixed brine enters the feed buffer tank 1, and when the liquid level in the feed buffer tank 1 reaches 20%, the first agitator starts automatically, and automatically stops when the liquid level is lower than 20%. The concentrated brine in the feed buffer tank 1 is transported to the calcium-removing magnesium reaction tank 3 through the first pump 2. When the liquid level of the reaction tank 3 is lower than 10%, the first pump 2 starts automatically, and the concentrated brine is delivered to the reaction tank 3; When the liquid level in the reaction tank 3 reaches 75%, the first pump 2 stops automatically, when the liquid level in the reaction tank 3 reaches 20%, the fifth agitator starts automatically, and stops automatically when the liquid level is lower than 20%.

[0050] When liquid level reaches 75% in decalcif...

Embodiment 2

[0062] The system of the present invention is used to treat the effluent of the concentrated brine obtained by the mechanical steam recompression evaporation technology of the seed crystal method. Among them, Table 1 is the effluent water quality table of mechanical vapor recompression evaporation technology with seed crystal method.

[0063] pH

Ca 2+

Mg 2+

Na +

K +

SO 4 2-

Cl -

F -

4~6

1200

3195

70000

601

1148

180942

26.5

NO 3 -

Br -

B

SiO 2

TDS

TSS

COD

Ammonia nitrogen

2.6

80

142

307

226016

46180

410

0.7

[0064] Table 1

[0065] Concentrated brine enters the feed buffer tank 1, and when the liquid level reaches 20%, the first agitator starts automatically, and stops automatically when the liquid level is lower than 20%. The concentrated brine is transported to the decalcification magnesium reaction tank 3 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com