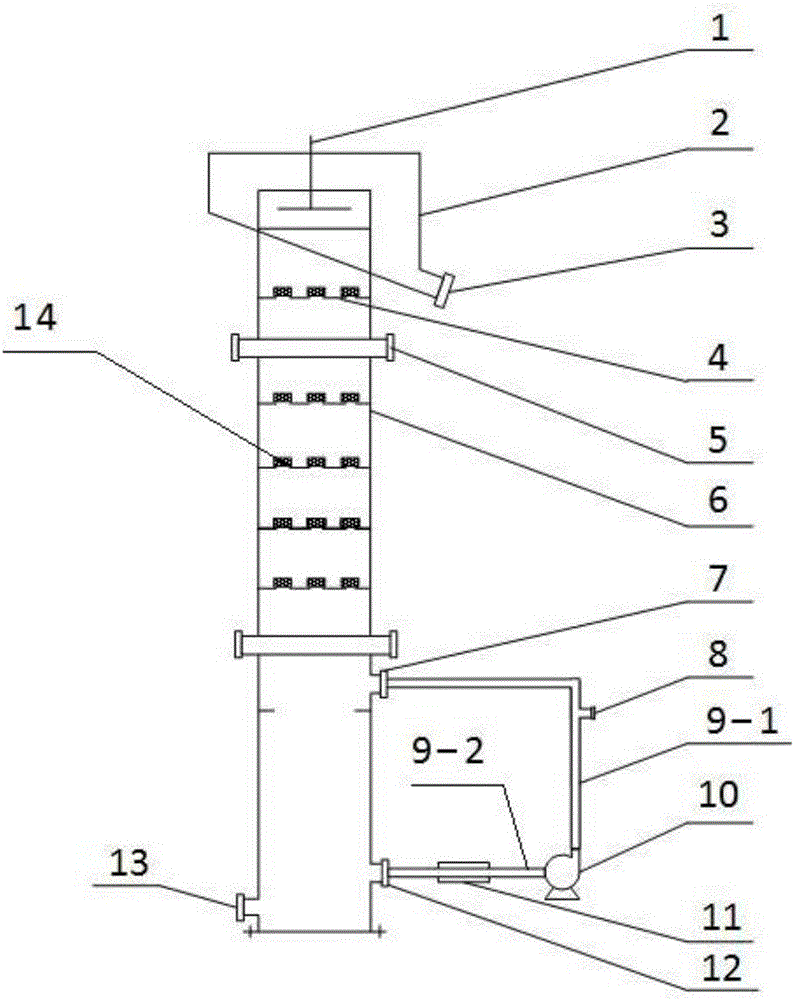

Flotation column separation equipment and separation method

A flotation column and separation technology, applied in flotation, solid separation and other directions, can solve the problems that the flotation column is difficult to achieve the ideal separation effect, the tailings grade is difficult to meet the requirements, and the countercurrent mineralization is not sufficient. The effect of ensuring the recovery rate of concentrate, improving the efficiency of beneficiation and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Ore sample from a mining area in Yichang, raw ore P 2 o 5 The grade is 24.64%, and the MgO content is 4.6%. First crush, grind and classify the raw phosphate ore, control the grinding fineness to -200 mesh > 80%, the concentration of the grinding slurry is 30%, and the flotation temperature is about 25°C, and then introduce the slurry into the mineralization tank , the pH value of the pulp is controlled to be 5.6, the fatty acid collector is fully mixed with the pulp at 2.5kg / t, and then the resulting mixture is introduced into the flotation column, and the pulp passes through one or more ore feeders located in the middle and upper part of the flotation column body The tube enters the flotation column, and after flotation, the phosphorous concentrate P 2 o 5 Grade 32.64%, MgO content 0.92%, P 2 o 5 The recovery rate reached 91.8%.

Embodiment 2

[0041] Ore sample from a mining area in Yichang, raw ore P 2 o 5 The grade is 24.84%, and the MgO content is 4.4%. Crushing, grinding and grading the raw phosphate ore, controlling the grinding fineness to -200 mesh > 80%, the concentration of the grinding slurry at 30%, the flotation temperature at about 25°C, adding fatty acid collectors 2.5kg / t, to control the pH value of the slurry to 5.2, the phosphorous concentrate P after flotation 2 o 5 Grade 32.34%, MgO content 0.84%, P 2 o 5 The recovery rate reaches 90.8%.

Embodiment 3

[0043] Ore sample from a mining area in Yichang, raw ore P 2 o 5 The grade is 23.37%, and the MgO content is 4.8%. Crushing, grinding and classifying raw phosphate ore, controlling the grinding fineness to -200 mesh > 80%, the concentration of the grinding slurry at 30%, the flotation temperature at about 25°C, adding fatty acid collector 2.7kg / t, the pH value of the control slurry is 5.8, and the phosphorus concentrate P after flotation 2 o 5 Grade 32.57%, MgO content 0.83%, P 2 o 5 The recovery rate reached 92.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com