Method for preparing nickel-based alloy by stepwise adding carbon in melting process

A nickel-based alloy, step-by-step technology, applied in the field of nickel-based alloys, can solve the problems of increasing the difficulty of composition control and reducing the deoxidation capacity of C in the alloy, and achieve the effects of reducing porosity, achieving precise control and improving the pass rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

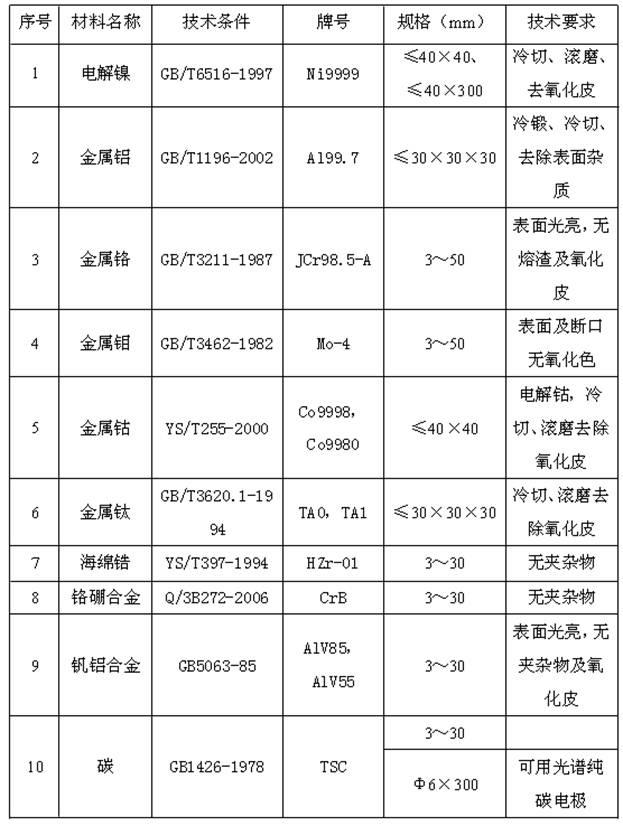

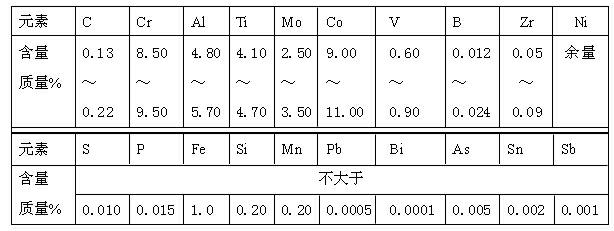

[0031] The process of adding carbon step by step during the smelting process to prepare the nickel-based alloy is as follows.

[0032] (1) Furnace loading

[0033] In the crucible from bottom to top, 68% of the total amount of Ni, 18% of the total amount of C, all of Co, all of Mo, all of Cr and the remaining Ni were loaded in sequence.

[0034] 18% of the total amount of C, the remaining C, V-Al, Al, Ti, CrB and Zr were separately charged in the feeding tank.

[0035] (2) Melting of the alloy

[0036] A vacuum induction melting furnace is used for smelting. When the vacuum degree of the vacuum induction melting furnace is ≤0.67Pa, the temperature starts to rise, and the temperature rise rate is controlled to be 7°C / min until the charge is melted.

[0037] (3) Alloy refining

[0038] When the vacuum degree of the vacuum induction melting furnace after alloying is ≤1.33Pa, the temperature is raised to a refining temperature of 1530°C at a heating rate of 15°C / min, and the re...

Embodiment 2

[0051] The process of adding carbon step by step during the smelting process to prepare the nickel-based alloy is as follows.

[0052] (1) Furnace loading

[0053] In the crucible from bottom to top, 70% of the total amount of Ni, 20% of the total amount of C, all of Co, all of Mo and all of Cr are sequentially loaded, and the remaining Ni is loaded into the feeding tank.

[0054] Separately charge 20% of the total amount of C, the remaining C, V-Al, Al, Ti, CrB and Zr in the feeding tank.

[0055] (2) Melting of the alloy

[0056] A vacuum induction melting furnace is used for smelting. When the vacuum degree of the vacuum induction melting furnace is ≤0.67Pa, the temperature starts to rise, and the temperature rise rate is controlled to be 10°C / min until the charge is melted. After the charge is melted, add the Ni in the feeding tank into the crucible.

[0057] (3) Alloy refining

[0058] When the vacuum degree of the vacuum induction melting furnace after alloying is ≤1...

Embodiment 3

[0071] The process of adding carbon step by step during the smelting process to prepare the nickel-based alloy is as follows.

[0072] (1) Furnace loading

[0073] In the crucible from bottom to top, 66% of the total amount of Ni, 16% of the total amount of C, all of Co, all of Mo, all of Cr and the remaining Ni were loaded in sequence.

[0074] 16% of the total amount of C, the remaining C, V-Al, Al, Ti, CrB and Zr were separately charged in the feeding tank.

[0075] (2) Melting of the alloy

[0076] A vacuum induction melting furnace is used for smelting. When the vacuum degree of the vacuum induction melting furnace is ≤0.67Pa, the temperature starts to rise, and the temperature rise rate is controlled at 5°C / min until the charge is melted.

[0077] (3) Alloy refining

[0078] When the vacuum degree of the vacuum induction melting furnace after alloying is ≤1.33Pa, the temperature is raised to the refining temperature of 1520°C at a heating rate of 10°C / min, and the ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com