High pressure conveyance gas recovery method

A high-pressure conveying and gas recovery technology, applied in conveyors, conveying bulk materials, transportation and packaging, etc., can solve problems such as energy waste, and achieve the effect of reducing energy waste, less investment and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

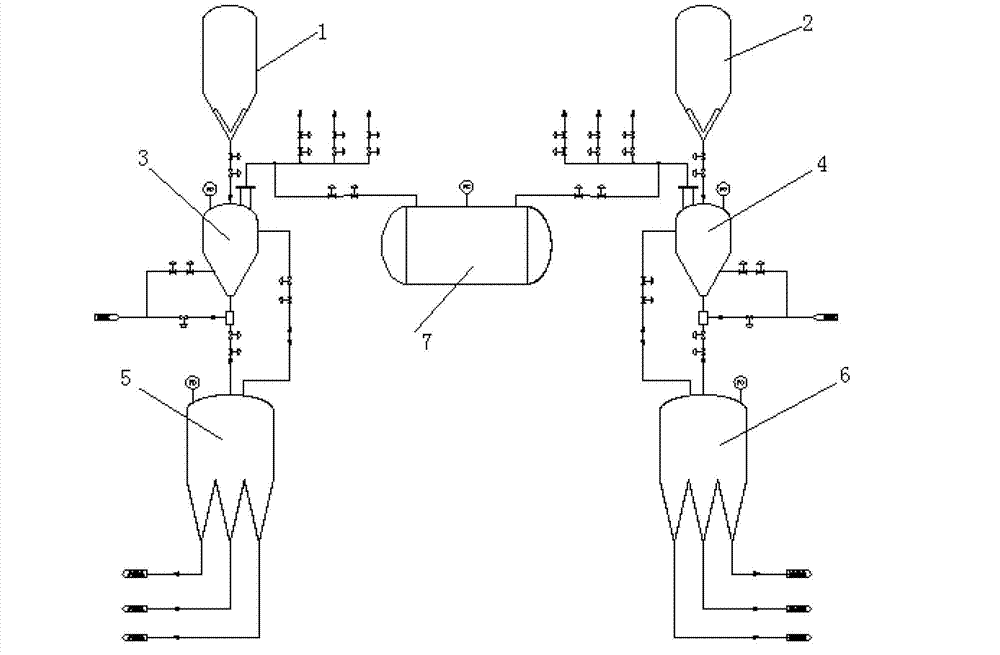

[0020] Referring to the attached drawings, a method for recovering high-pressure conveying gas includes a first storage tank 1, a second storage tank 2, a first lock hopper 3, a second lock hopper 4, a first feed tank 5, and a second feed tank 6 , Gas coupling tank 7, specifically including the following steps:

[0021] a. Storage tank discharge step: the powder in the first storage tank 1 and the second storage tank 2 respectively enters the first lock hopper 3 and the second lock hopper 4 by gravity;

[0022] b. Locking hopper pressurization step: After the first lock hopper 3 and the second lock hopper 4 are filled with powder, they are isolated from the corresponding first storage tank 1, second storage tank 2 and all low-pressure equipment, and communicate with the first lock hopper 3 , The second lock bucket 4 and the gas coupling tank 7 are pressure equalized. After the pressure is balanced, the gas coupling tank 7 is isolated, and the first lock bucket 3 and the second lock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com