U-shaped pipe pressure meter and pressure measurement method thereof

A U-shaped tube and pressure gauge technology, which is applied to the U-shaped tube pressure gauge and its measurement field, can solve the problems of measurement error of local air column of bubbles, inconvenient liquid level height value, large measurement error, etc., so as to achieve pressure measurement, The measurement method is ingenious and novel, and the effect of improving the measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

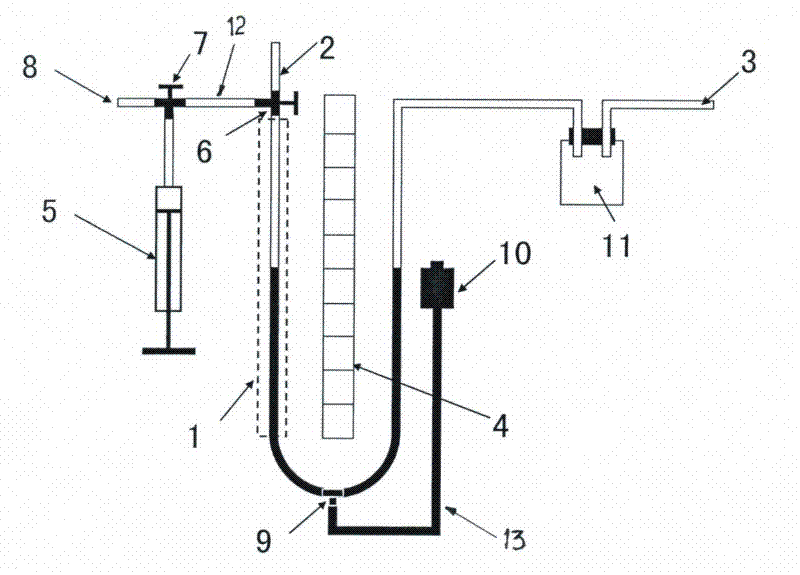

[0023] In the figure: 1. U-shaped tube (with volume scale); 2. High-pressure measuring port tube; 3. Low-pressure measuring port tube; 4. Scale; 5. Piston-type gas cylinder; 6. The first three-way valve; 7. No. 2 three-way valve; 8. Empty pipe; 9. No. 3 three-way valve; 10. Liquid filling tank; 11. Overpressure overflow protection tank; 12. Connecting pipe; 13. Liquid filling pipe.

[0024] figure 1 As shown, the present invention mainly consists of a vertically installed U-shaped pipe 1. The bottom of the U-shaped pipe 1 is connected with a liquid-feeding pipe 13 through a tee 9. The liquid-feeding pipe consists of a vertically downward segment, a horizontal segment, and a vertically upward segment The top of the vertical upward section of the liquid feeding pipe is connected with the liquid adding tank 10. The liquid adding tank is filled with pressure measuring medium and sealed by the cover. The right pipe section of the U-shaped pipe extends horizontally and then along th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com