Quasi-thin empholite composition containing organic reaming agent

A pseudo-boehmite and organic pore-enlarging agent technology, applied in chemical/physical process, catalyst activation/preparation, physical/chemical process catalyst, etc., can solve the problems of poor pore-enlarging effect and large content of organic pore-enlarging agent , to achieve the effect of low crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0036] Adopt aluminum hydroxide (Shandong aluminum plant product) and sodium hydroxide (Beijing chemical plant product) reaction preparation concentration to be the NaAlO of 200 grams alumina / liter 2 solution, this solution was mixed with a concentration of 90 grams of alumina / liter of Al2 (SO 4 ) 3 Solution (Changling Oil Refinery Catalyst Factory product) joins in the gel forming tank of a 2 liters simultaneously with the mode of concurrent flow, puts 1.5 liters of water in advance in the tank, NaAlO 2 The flow rate of the solution is 1.1 liters / hour, adjust the Al 2 (SO 4 ) 3 The flow rate of the solution is such that the gelling pH value is 8, and the temperature of the gelling process is 50°C. The slurry generated by the gelling is collected in an aging tank. After collecting for 20 minutes, the slurry is switched to another aging tank for collection. Add sodium carbonate to the collected aging tank to adjust the pH to 10, then age for 50 minutes, filter, and wash 4 t...

example 2

[0038] NaAlO with a concentration of 240 g alumina / L 2 Solution (preparation method is the same as example 1) and concentration is the Al(NO of 50 grams of alumina / liters) 3 ) 3 (product of Beijing Chemical Factory) the solution is added into a 2-liter gel-forming tank simultaneously in a co-current manner, and 1.5 liters of water, NaAlO 2 The flow rate of the solution is 1.1 liters / hour, adjust the Al(NO 3 ) 3 The flow rate of the solution is such that the gelling pH value is 7.5, and the temperature of the gelling process is 35°C. The slurry generated by the gelling process is collected in an aging tank. After collecting for 20 minutes, the slurry is switched to another aging tank for collection. The slurry in the aging tank that has been collected is aged for 150 minutes, filtered, and washed twice with 30 times 55°C deionized water to prepare 8 kg of pseudo-boehmite wet filter cake, and take 50 grams of the wet filter cake at 110°C After drying for 8 hours, the relativ...

example 3

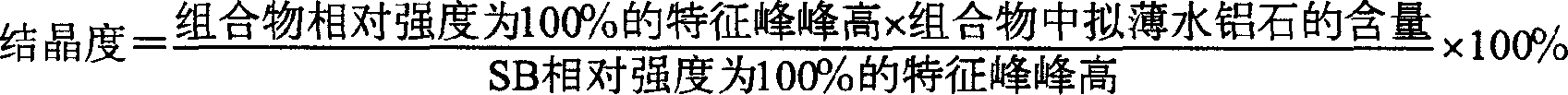

[0040] Get 20 liters of concentration and be the sodium metaaluminate solution (preparation method is the same as example 1) of 20 grams of aluminum oxide / liter, be placed in a 25 liters of gelling tank, initial temperature 15 ℃, pass into carbon dioxide from the bottom of gelling tank The mixed gas of carbon dioxide and air with a content of 30% by volume, the flow rate of the mixed gas is 35 m3 / hour, and the reaction takes 5 minutes, and the pH value drops to 6.8 (end point pH value). At this time, the reaction temperature is 28 ° C, and the gelation reaction ends , filtered, beating and washing with 20 times of 45°C deionized water for 5 times, and finally obtained pseudo-boehmite wet filter cake by filtering, gelling and washing twice in the same way, and a total of about 8 kg of pseudo-boehmite wet filter cake was obtained. Filter cake, get this wet filter cake 50 grams and dry at 130 ℃ for 3 hours, its relative crystallinity measured by X-ray diffraction is 58%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com