Polylactic acid foamed material and preparation method thereof

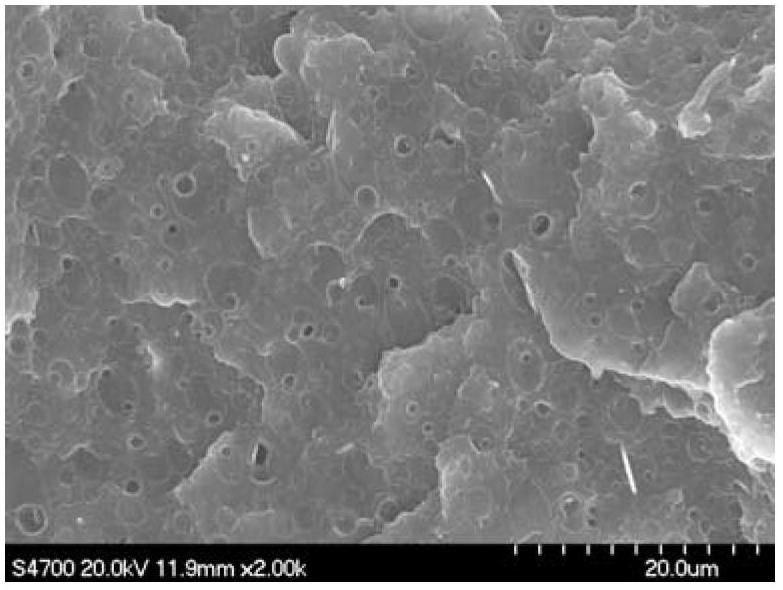

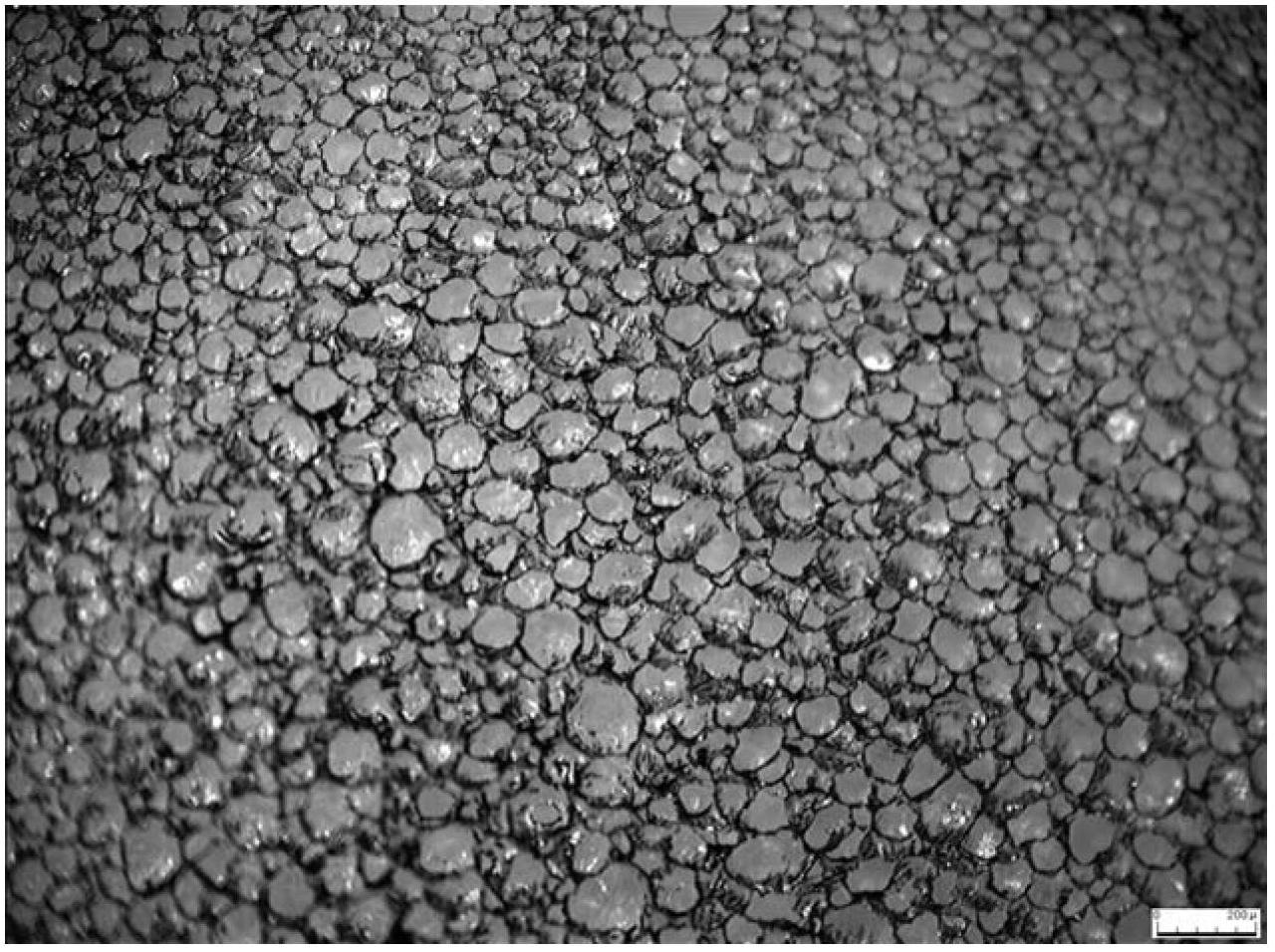

A technology of microcellular foaming material and polylactic acid, which is applied in the field of polylactic acid foaming material and its preparation, can solve the problems of high opening rate, large cell size, and unevenness, and achieve high closed cell rate and high cell density. The effect of small size and uniform cell size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

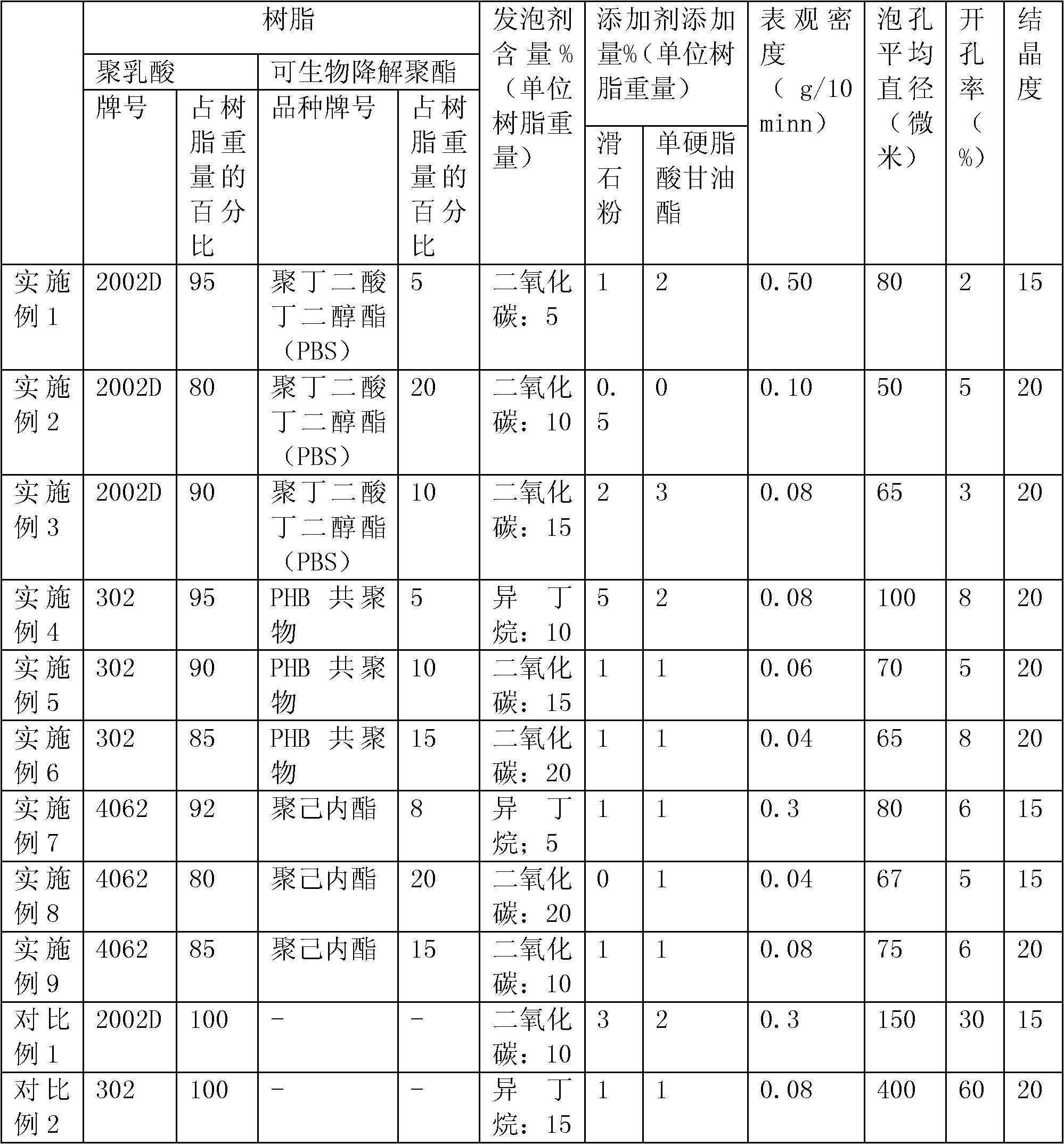

Embodiment 1

[0036] Raw material: polylactic acid, 2002D, Natureworks company, D-isomer content is 4%, melt flow rate is 3.0g / 10min.

[0037] Polybutylene succinate, HX-E201, Anqing Hexing Chemical Co., Ltd. Talc powder, 1250 mesh, Beijing Liguoweiye Powder Material Co., Ltd. Glyceryl monostearate was purchased from Shenyang Kerui Chemical Co., Ltd. Carbon dioxide, purity 99.5%, Beijing Oxygen Factory.

[0038] Foaming process: weigh polylactic acid, polybutylene succinate, talcum powder and glyceryl monostearate according to a certain ratio (as shown in Table 1), and mix them uniformly in a high-speed mixer. The mixed material is fed into the rotating twin-screw extruder, and a certain proportion of carbon dioxide is pumped into the polymer melt in the extruder through the metering pumping system. Under the rotation of the screw, the injected carbon dioxide and polylactic acid resin melt form a homogeneous solution, which is transported to the outlet of the machine head. The outlet of ...

Embodiment 2-3

[0042] The foaming process using the same raw material as in Example 1 is different in that the ratio of each component in the raw material is different, and the head pressure is different.

Embodiment 3

[0043] The foamed sheet obtained in Example 3 was heat-treated in an oven at 100°C for 60 seconds, and the obtained sample was measured by DSC for its melting exothermic peak at a rate of 10°C / min. The melting enthalpy of 93J / g indicates the degree of crystallinity. The properties of the foamed material obtained are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com