A kind of acrylonitrile-butadiene rubber that adopts paste system foaming and preparation method

A nitrile rubber and system technology, applied in the field of polymer material preparation, can solve the problems of difficult effective matching of foaming and crosslinking processes, low energy consumption, etc., achieve good environmental friendliness, save raw material costs, and small cell size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of acrylonitrile-butadiene rubber that adopts pasty system foaming and preparation method, its concrete process of preparing foamed acrylonitrile-butadiene rubber is as follows:

[0032] Grind 10kg of semi-vulcanized nitrile rubber (acrylonitrile content is 25-30%, vulcanization degree is 30-40%) to make 100-200 mesh powder, then add 0.5kg cyclopentane, 0.3kg polybutylene Diene, stirred at a speed of 100r / min for 20min to make it evenly mixed to obtain a paste; then add 0.02kg of sulfur, 0.1kg of accelerator D, 1kg of calcium silicate, and 0.5kg of stearic acid into the paste , 0.1kg anti-aging agent RD and 0.05kg salicylic acid, stir evenly, introduce into the mold, make it foam at 50-60°C, wait for the mold to be filled, heat up to 120-130°C to solidify, and demould to obtain foamed Nitrile rubber.

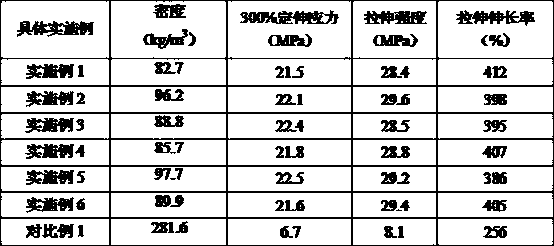

[0033] The foamed nitrile rubber obtained in Example 1 was tested for its density and mechanical properties, and the obtained data are shown in Table 1.

[0034]...

Embodiment 2

[0036] A kind of acrylonitrile-butadiene rubber that adopts pasty system foaming and preparation method, its concrete process of preparing foamed acrylonitrile-butadiene rubber is as follows:

[0037]Grind 12kg of semi-vulcanized nitrile rubber (acrylonitrile content is 25-30%, vulcanization degree is 30-40%) to make 100-200 mesh powder, then add 0.0.6kg cyclopentane, 0.4kg poly Butadiene was stirred at a speed of 100r / min for 30min to make it evenly mixed to obtain a paste; then add 0.024kg sulfur, 0.12kg accelerator TMTD, 1.2kg white carbon black, 0.6kg hard Fatty acid, 0.12kg anti-aging agent D and 0.06kg phthalic anhydride, stir evenly, introduce into the mold, make it foam at 50-60°C, wait for the mold to be filled, heat up to 120-130°C for curing, and release the mold. A foamed nitrile rubber is obtained.

[0038] The foamed nitrile rubber obtained in Example 2 was tested for its density and mechanical properties, and the obtained data are shown in Table 1.

[0039] As...

Embodiment 3

[0041] A kind of acrylonitrile-butadiene rubber that adopts pasty system foaming and preparation method, its concrete process of preparing foamed acrylonitrile-butadiene rubber is as follows:

[0042] Grind 15kg of semi-vulcanized nitrile rubber (the acrylonitrile content is 25-30%, and the degree of vulcanization is 30-40%) to make a powder with a particle size of 100-200 mesh, and then add 0.75kg cyclopentane and 0.5kg polybutylene Diene, stirred at a speed of 90r / min for 20min to make it evenly mixed to obtain a paste; then add 0.03kg of sulfur, 0.15kg of accelerator D, 1.5kg of calcium silicate, 0.8kg of hard Fatty acid, 0.15kg anti-aging agent RD and 0.07kg salicylic acid are mixed evenly and then introduced into the mold to make it foam at 50-60°C. Bubble nitrile rubber.

[0043] The foamed nitrile rubber obtained in Example 3 was tested for its density and mechanical properties, and the obtained data are shown in Table 1.

[0044] As can be seen from the data in Table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com