Polypropylene composition for low foaming and preparation process thereof

A polypropylene composition and low-foaming technology, which is applied in the field of low-foaming polypropylene composition and its preparation, can solve the problems of affecting the rigidity of materials, increasing material costs, energy saving and weight reduction effects of products are not obvious, and achieve Good processing performance, small and uniform cell size, and excellent comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

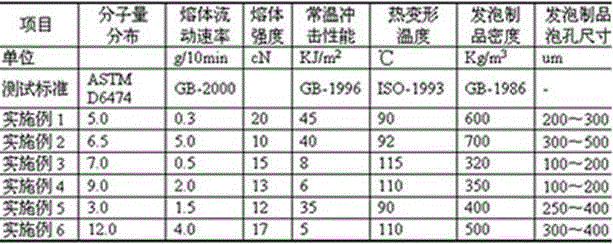

Examples

Embodiment 1

[0021] 100 parts of copolymerized polypropylene;

[0022] Tetrakis[methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester 0.1 part;

[0023] 0.1 parts of tris(2,4-di-tert-butyl)phenyl phosphite;

[0024] 1.0 parts of talcum powder;

[0025] 5.0 parts of glycerol monostearate.

Embodiment 2

[0027] 100 parts of copolymerized polypropylene;

[0028] 0.5 parts of tetrakis[methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester;

[0029] 0.5 parts of tris(2,4-di-tert-butyl)phenylphosphite;

[0030] 2.0 parts of talcum powder;

[0031] 8.0 parts of glycerol monostearate.

Embodiment 3

[0033] 100 parts of homopolypropylene;

[0034] Tetrakis[methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester 1.0 parts;

[0035] 1.0 parts of tris(2,4-di-tert-butyl)phenylphosphite;

[0036] 5.0 parts of talcum powder;

[0037] 10.0 parts of glycerol monostearate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com