TiC/Ti5Si3 enhanced copper-based composite and preparing method thereof

A copper-based composite material and composite material technology, applied in the field of metal materials, can solve the problems of complex preparation process, high cost, and low production efficiency, and achieve the effect of simple and stable preparation process, fine particles, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

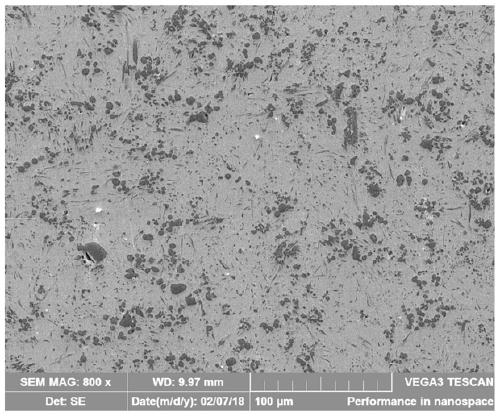

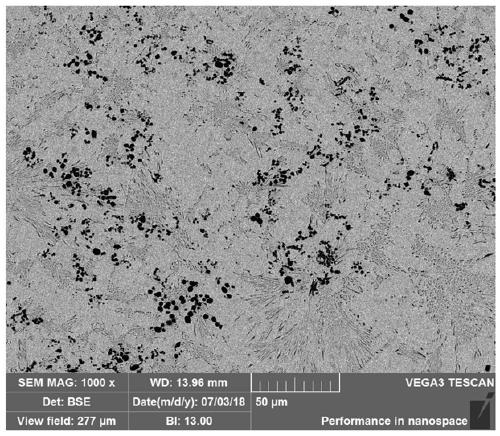

Image

Examples

Embodiment 1

[0024] (1) Raw material preparation: ready to prepare TiC / Ti 5 Si 3 The raw materials needed to strengthen the copper-based composite material are weighed by mass percentage, including 89.21% of pure copper, 1.07% of crystalline silicon, 0.43% of Si powder, 8.29% of titanium powder and 1% of graphite powder.

[0025] (2) Preparation of Ti-Si-graphite mixed powder: fully mix Si powder, Ti powder and graphite powder in a mixer for 0.5 hour to obtain Ti-Si-graphite mixed powder.

[0026] (3) Powder briquetting and sintering: cold press the Ti-Si-graphite mixed powder obtained in (2) into a prefabricated block of a certain shape under a pressure of 30MPa, and place the prefabricated block in a vacuum sintering furnace at 650°C Sinter for 2 hours, or sinter for 2 hours in a vacuum hot pressing sintering furnace at 650° C. under a pressure of 30 MPa to obtain a Ti-Si-graphite prefabricated block.

[0027] (4)TiC / Ti 5 Si 3 Preparation of reinforced copper-based composite material...

Embodiment 2

[0030] (1) Raw material preparation: ready to prepare TiC / Ti 5 Si 3 The raw materials needed to strengthen the copper-based composite material are weighed by mass percentage, 88.64% of pure copper, 0.72% of crystalline silicon, 0.28% of Si powder, 8.86% of titanium powder and 1.5% of graphite powder.

[0031] (2) Preparation of Ti-Si-graphite mixed powder: fully mix Si powder, Ti powder and graphite powder in a mixer for 1 hour to obtain Ti-Si-graphite mixed powder.

[0032] (3) Powder briquetting and sintering: cold press the Ti-Si-graphite mixed powder obtained in (2) into a prefabricated block of a certain shape under a pressure of 50MPa, and place the prefabricated block in a vacuum sintering furnace at 750°C Sinter for 3 hours, or sinter for 3 hours in a vacuum hot pressing sintering furnace at 750° C. under a pressure of 50 MPa to obtain a Ti-Si-graphite prefabricated block.

[0033] (4)TiC / Ti 5 Si 3 Preparation of reinforced copper-based composite materials: After t...

Embodiment 3

[0036] (1) Raw material preparation: ready to prepare TiC / Ti 5 Si 3 The raw materials needed to strengthen the copper-based composite material are weighed by mass percentage, including 82.28% of pure copper, 1.52% of crystalline silicon, 0.48% of Si powder, 13.72% of titanium powder and 2% of carbon black.

[0037] (2) Preparation of Cu-Ti-Si-carbon black mixed powder: fully mix Si powder, Ti powder and graphite powder in a mixer for 3 hours to obtain Ti-Si-carbon black mixed powder.

[0038] (3) Powder briquetting and sintering: The Cu-Ti-Si-carbon black mixed powder obtained in (2) is cold-pressed into a prefabricated block of a certain shape under a pressure of 70 MPa, and the prefabricated block is placed in a vacuum of 800 ° C Sintering in a sintering furnace for 4 hours, or sintering in a vacuum hot-pressing sintering furnace at 800° C. under a pressure of 70 MPa for 4 hours to obtain a Cu-Ti-Si-carbon black prefabricated block.

[0039] (4)TiC / Ti 5 Si 3 Preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com