Continuous hot-dip aluminum-silicon-magnesium alloy steel plate, preparation method thereof and plating solution

A hot-dip aluminum and alloy steel plate technology, applied in the hot-dip plating process, metal material coating process, coating, etc., can solve the problems that limit the application and promotion of hot-dip aluminum steel plate, the cut surface does not have electrochemical protection, and hinder Aluminum to steel galvanic activation and other issues, to achieve the effect of improving the protection performance of the cut surface, the manufacturing process is simple and stable, and the manufacturing cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

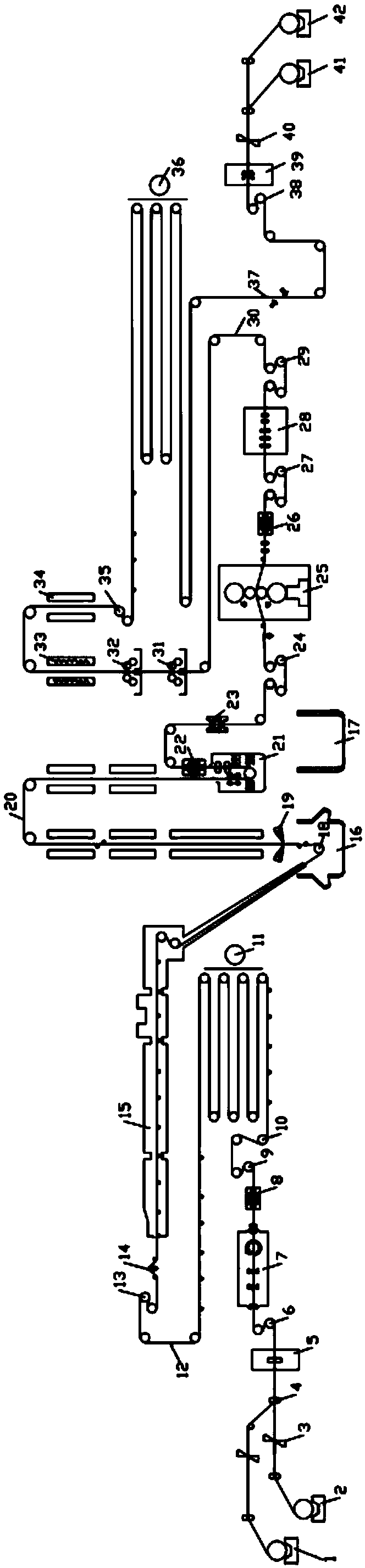

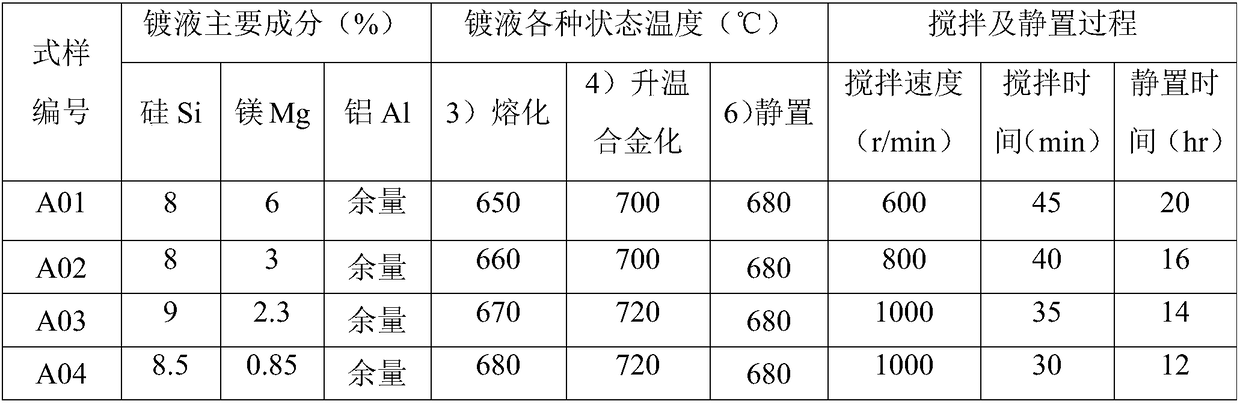

[0051] The continuous hot-dip aluminum-silicon-magnesium alloy steel plate is prepared by the following method:

[0052] 1. Bath preparation.

[0053] 1) Calculate the quantity of aluminum-silicon alloy ingots and aluminum-magnesium alloy ingots according to the predetermined alloy composition ratio and the weight of the required plating bath.

[0054] 2) Prepare tools such as mechanical agitator with adjustable speed, submersible hanging basket, flour slag fisher, safety mask, protective clothing and other safety equipment;

[0055] 3) Preheat the aluminum-silicon alloy ingot and other tools to be placed in the induction heating furnace (or called a plating tank) to above 200°C, then put the aluminum-silicon alloy ingot into the induction heating furnace to melt, and the melting heating temperature is : 650~700℃;

[0056] 4) After the above-mentioned aluminum-silicon alloy ingot is completely melted, put the aluminum-magnesium alloy ingot into the submerged hanging basket, ...

Embodiment 2

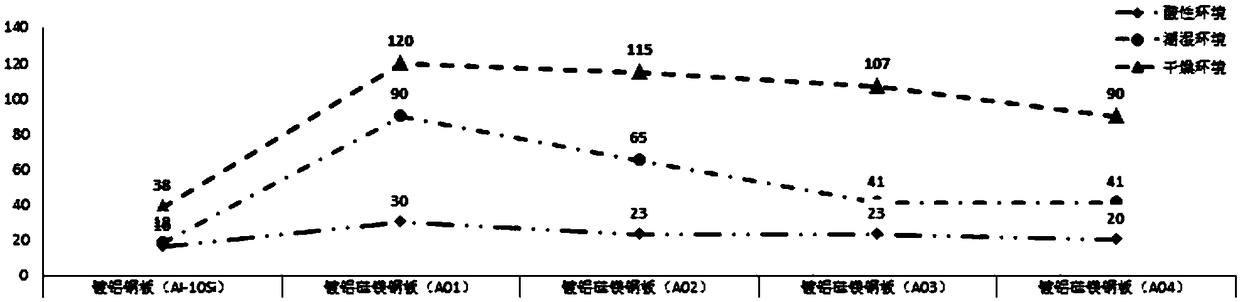

[0081] The alloy steel sheets with different aluminum-silicon-magnesium alloy components prepared in the above-mentioned embodiment 1 were sampled respectively, compared with the conventional aluminum-coated steel sheets (Al-10Si), respectively simulated in acidic environment, wet environment, and dry environment to test, and observe the cut-off It is time for the surface to start to produce red rust under the same environment.

[0082] The above-mentioned aluminum-coated steel sheet is prepared with reference to the method of Example 1, and the difference from the alloy steel sheet prepared in Example 1 is that the composition of the plating solution is different. The main components of the aluminum-coated steel sheet for comparison are: 10% Si and the balance of Al

[0083] 1. Placement experiment in humid environment.

[0084] Place the alloy steel plate above for 18 hours in a humid environment with a relative humidity greater than 80% (such as basement, rainy weather in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com