Thermotropic liquid crystal polymer fiber composite polyphenylene sulfide foam material and preparation method thereof

A technology of thermotropic liquid crystal and polyphenylene sulfide, applied in the field of polymer materials, to achieve the effect of increasing cell density, enhancing mechanical properties, and uniform cell diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The embodiment of the present application provides a method for preparing a thermotropic liquid crystal polymer fiber composite polyphenylene sulfide foam material, comprising the following steps:

[0037] Preparation of polyphenylene sulfide / thermotropic liquid crystal polymer fiber composite sheet;

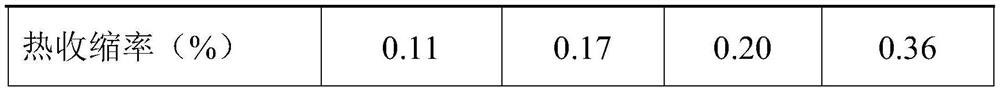

[0038] Put the polyphenylene sulfide / thermotropic liquid crystal polymer fiber composite sheet in the reactor, and then pass through the supercritical fluid foaming agent to make the pressure in the reactor be 3.3-25Mpa, and keep the temperature in the reactor at 0 ~280°C and maintain it for a certain period of time, raise the temperature to 200-330°C and keep it for 5-25 minutes, and then release the pressure in the reactor to normal pressure within 5-100s to prepare the thermotropic liquid crystal polymer fiber composite polyphenylene Sulfide foam;

[0039]Alternatively, the polyphenylene sulfide / thermotropic liquid crystal polymer fiber composite sheet is placed in th...

Embodiment 1

[0066] The embodiment of the present application provides a method for preparing a thermotropic liquid crystal polymer fiber composite polyphenylene sulfide foam material, comprising the following steps:

[0067] S1. After mixing 100 parts of polyphenylene sulfide fibers and 2 parts of thermotropic liquid crystal polymer fibers, they are opened, and then beaten with water as a dispersion medium. The mass concentration of the beating is 1% to obtain a slurry; The average diameter of ether fibers is 15 μm, and the average diameter of thermotropic liquid crystal polymer fibers is 5 μm;

[0068] S2. Put the slurry in a fiber deflagging machine to decompose to obtain a polyphenylene sulfide fiber / thermotropic liquid crystal polymer fiber composite slurry, wherein the rotational speed during decompression is 2700 rad / min, and the decompression time is 20 minutes;

[0069] S3. Put the composite slurry on a cylinder paper machine for wet papermaking, wherein the netting concentration ...

Embodiment 2

[0075] The embodiment of the present application provides a method for preparing a thermotropic liquid crystal polymer fiber composite polyphenylene sulfide foam material, comprising the following steps:

[0076] S1. Mix 100 parts of polyphenylene sulfide and 3 parts of thermotropic liquid crystal polymer, then knead in a twin-screw extruder, and form a blended melt after extrusion; wherein the extrusion of the twin-screw extruder Outlet temperature is 285~355℃;

[0077] S2. Transport the blended melt to spinning equipment, and spin to obtain polyphenylene sulfide / thermotropic liquid crystal polymer composite fibers; wherein the spinning temperature is 330°C, and the average diameter of the composite fibers is 30 μm, wherein the thermotropic Liquid crystal polymers form ultrafine fibers from 500nm to 1.5 microns in polyphenylene sulfide matrix fibers;

[0078] S3, placing the composite fiber on a web forming machine to obtain 140g / m 2 Polyphenylene sulfide / thermotropic liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com