Patents

Literature

36 results about "Ethylbenzene hydroperoxide" patented technology

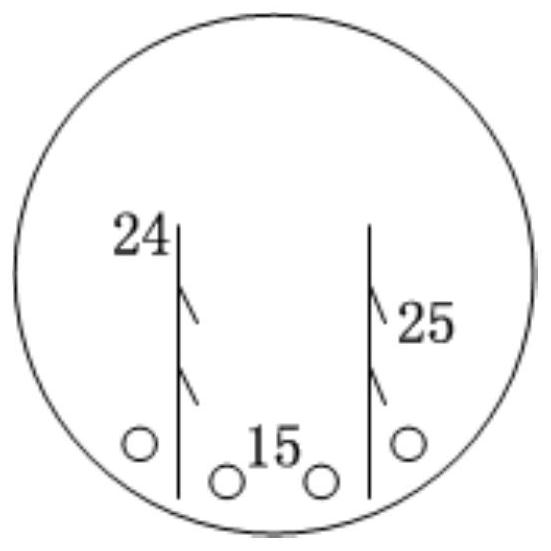

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

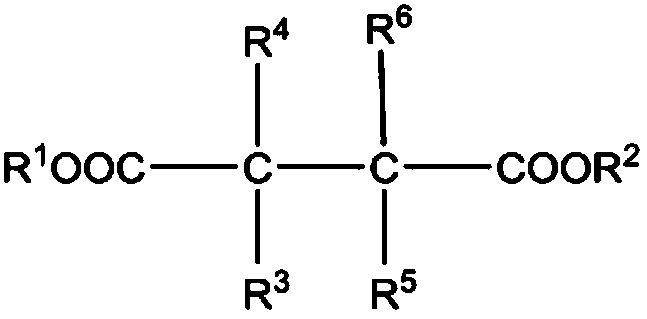

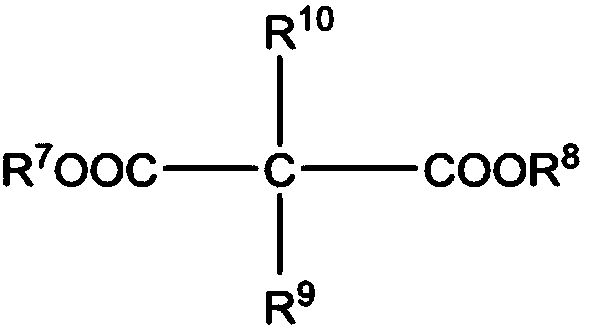

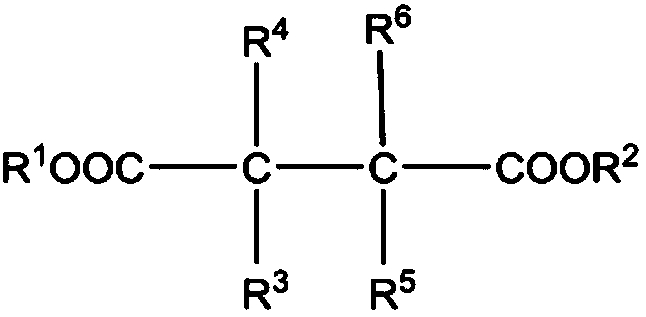

Titanium-containing silicon oxide catalyst

A titanium-containing silicon oxide catalyst satisfying all of the following conditions (1) to (4):(1): an average pore size of 10 Å or more,(2): a pore size of 90% or more of the total pore volume of 5 to 200 Å,(3): a specific pore volume of 0.2 cm3 / g or more, and(4): a quarternary ammonium ion represented by the following general formula (I) is used as a template and then said template is removed by solvent extraction operation;wherein, R1 represents a linear or branched hydrocarbon chain having 2 to 36 carbon atoms, and R2 to R4 represent an alkyl group having 1 to 6 carbon atoms, a method for producing said catalyst, and a method for producing propylene oxide by reacting propylene with a hydroperoxide, except for ethylbenzene hydroperoxide, in the presence of said catalyst.

Owner:SUMITOMO CHEM CO LTD

Method for producing propylene oxide

InactiveUS6211388B1Molecular sieve catalystsOrganic chemistry methodsEthylbenzene hydroperoxideQuaternary ammonium ions

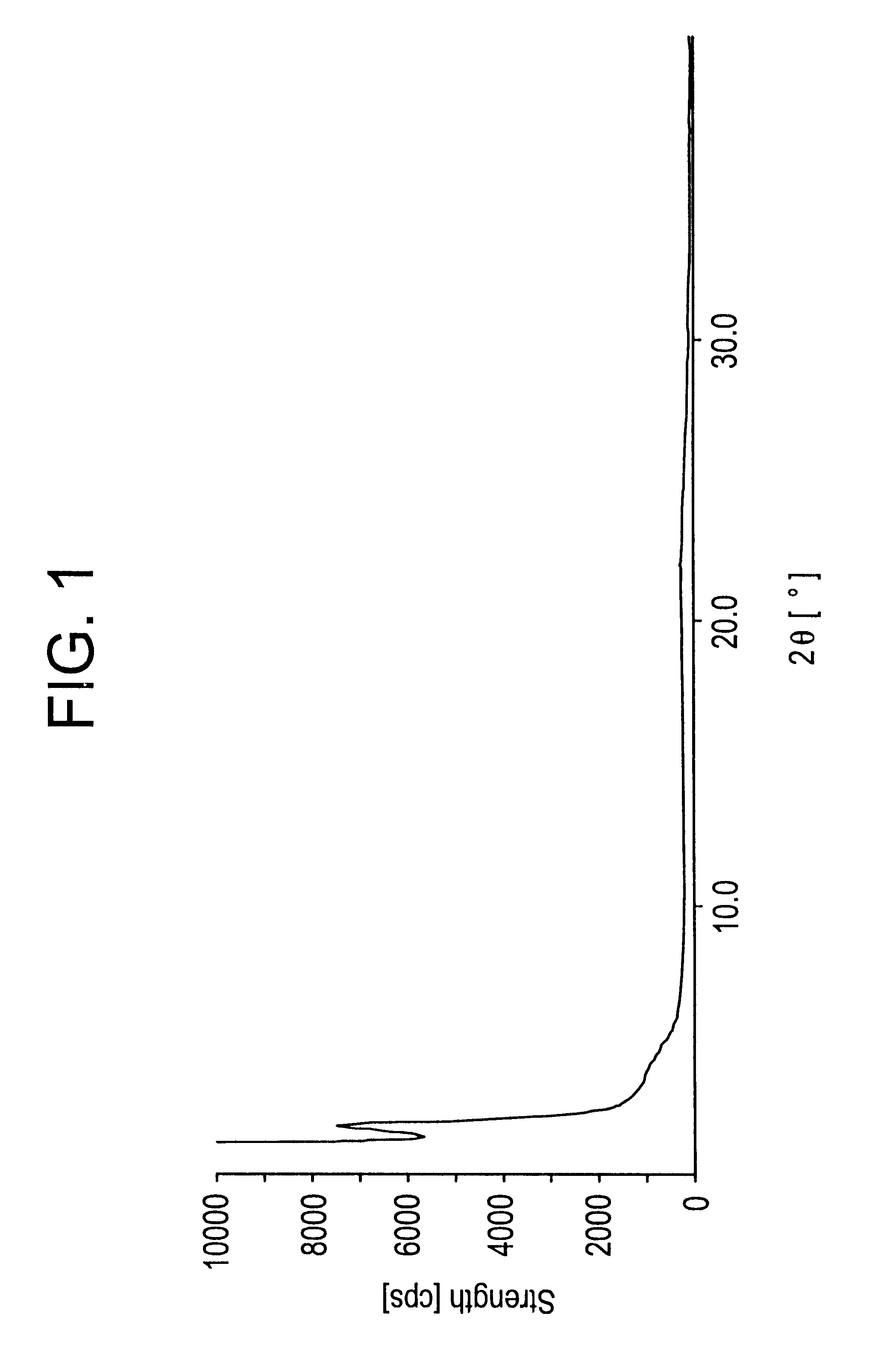

A method for producing propylene oxide by reacting propylene with ethylbenzene hydroperoxide, wherein the reaction is conducted in the presence of a catalyst comprising a titanium-containing silicon oxide and satisfying all of the following conditions (1) to (6):(1) there is at least one peak showing a interplanar spacing (d) larger than 18 Å in X-ray diffraction;(2) an average pore size is 10 Å or more;(3) a pore size of 90% or more of the total pore volume is 5 to 200 Å;(4) a specific pore volume is 0.2 cm3 / g or more;(5) a quaternary ammonium ion represented by the following general formula (I) is used as a template and then said template is removed by calcination operation:wherein R1 represents a linear or branched hydrocarbon chain having 2 to 36 carbon atoms, and R2 to R4 represent an alkyl group having 1 to 6 carbon atoms; and(6) The catalyst has been subjected to silylation treatment.

Owner:SUMITOMO CHEM CO LTD

Process for producing propylene oxide

A process for producing propylene oxide by reacting propylene with ethylbenzene hydroperoxide in the presence of a titanium-containing silicon oxide catalyst satisfying all of the following conditions (1) to (4): (1): an average pore size of 10 ANGSTROM or more, (2): a pore size of 90% or more of the total pore volume of 5 to 200 ANGSTROM , (3): a specific pore volume of 0.2 cm3 / g or more, and (4): a quarternary ammonium ion represented by the following general formula (I) is used as a template and then said template is removed by solvent extraction operation;[NR1R2R3R4]+(I) wherein, R1 represents a linear or branched hydrocarbon chain having 2 to 36 carbon atoms, and R2 to R4 represent an alkyl group having 1 to 6 carbon atoms.

Owner:SUMITOMO CHEM CO LTD

Process using a titanium-containing silicon oxide catalyst

InactiveUS6512128B2Organic chemistryMolecular sieve catalystsEthylbenzene hydroperoxideSilicon oxide

Owner:SUMITOMO CHEM CO LTD

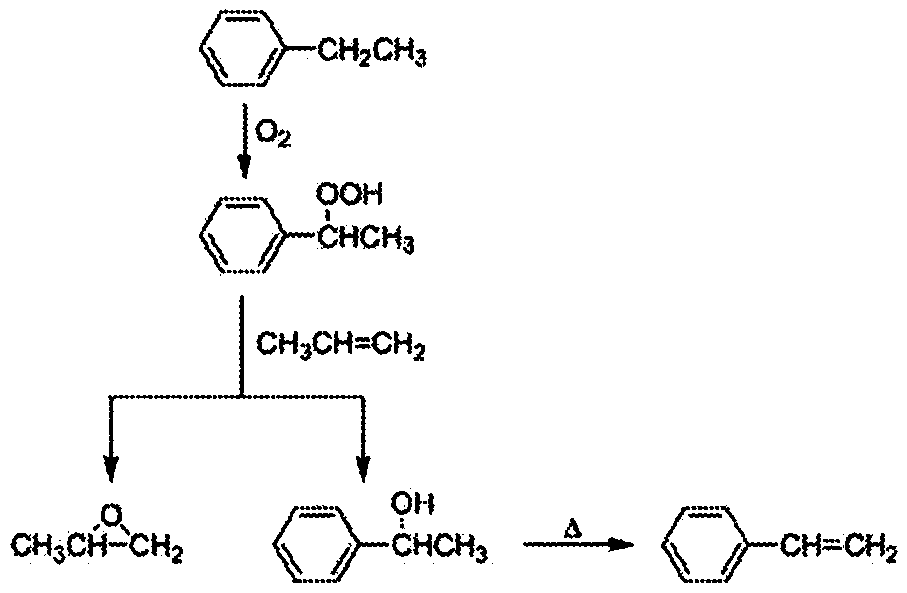

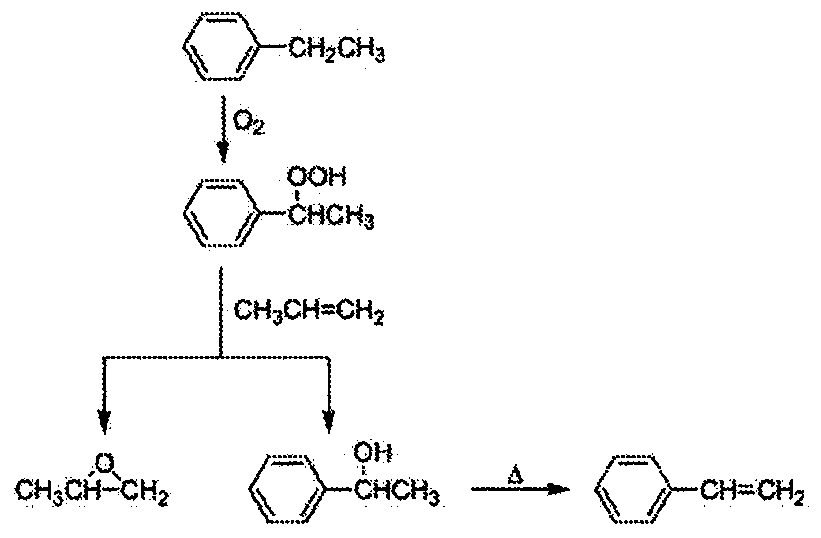

Method for preparing ethylbenzene hydroperoxide through oxidation of ethylbenzene

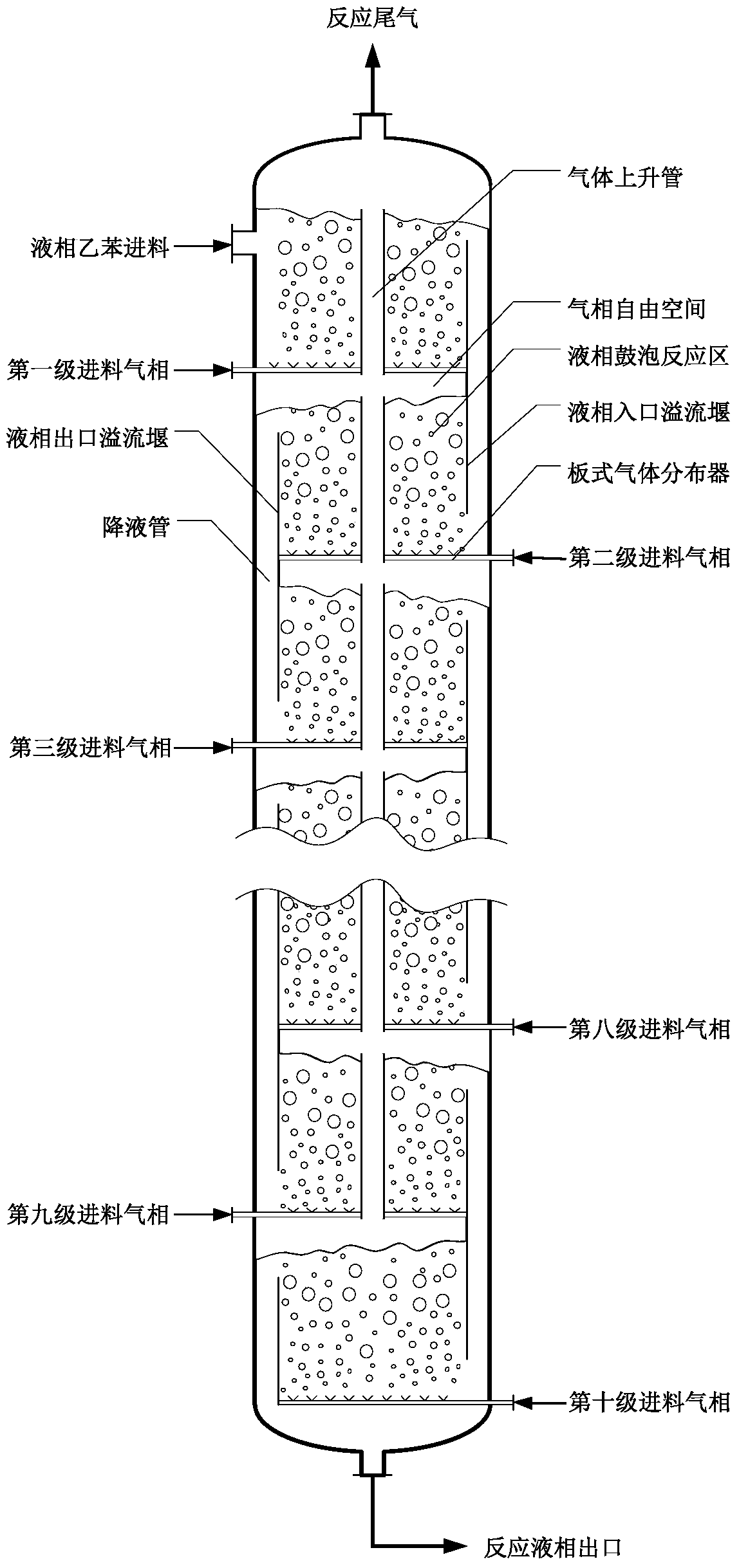

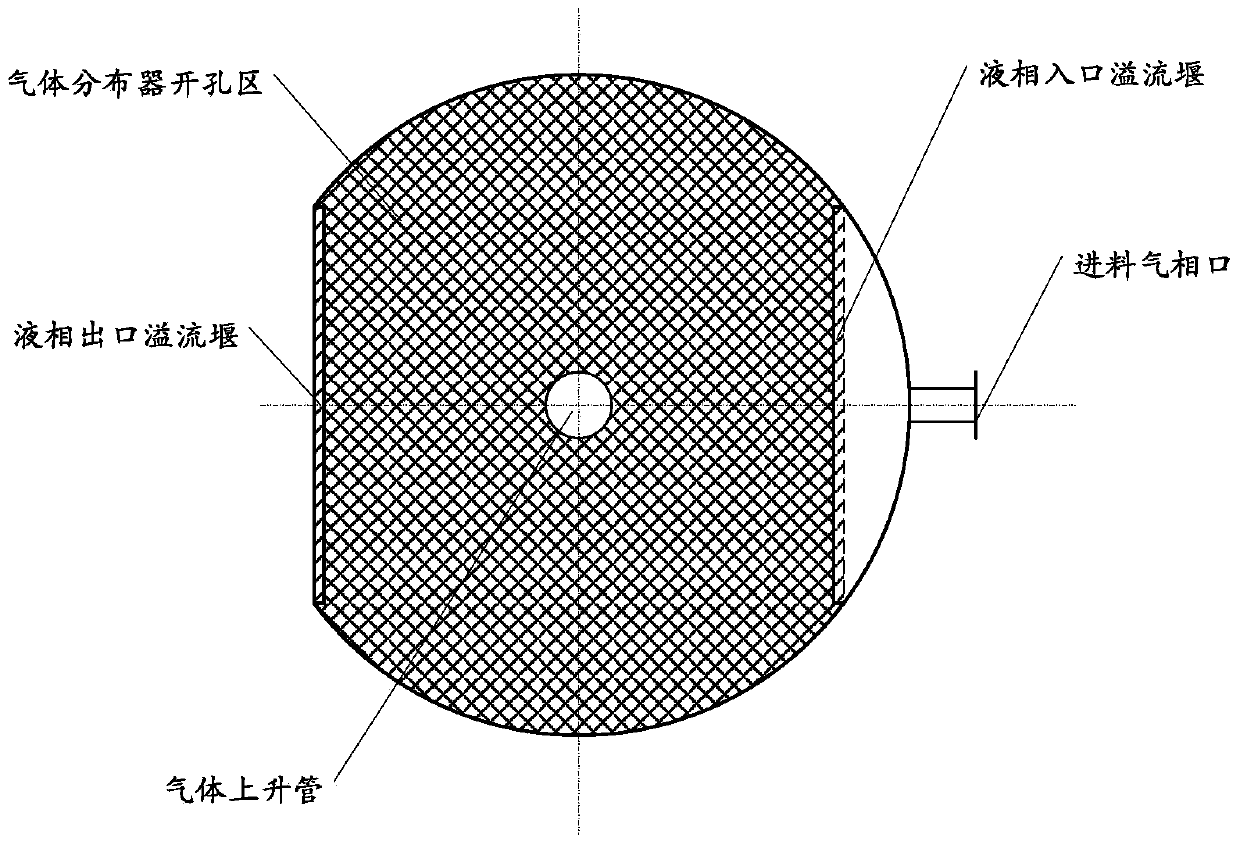

ActiveCN106554298AOrganic compound preparationLiquid-gas reaction processesEthylbenzene hydroperoxideEconomic benefits

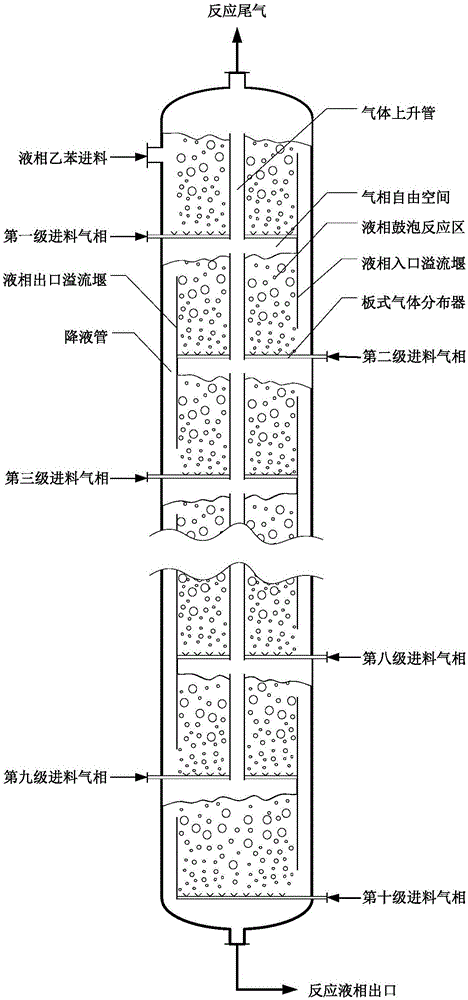

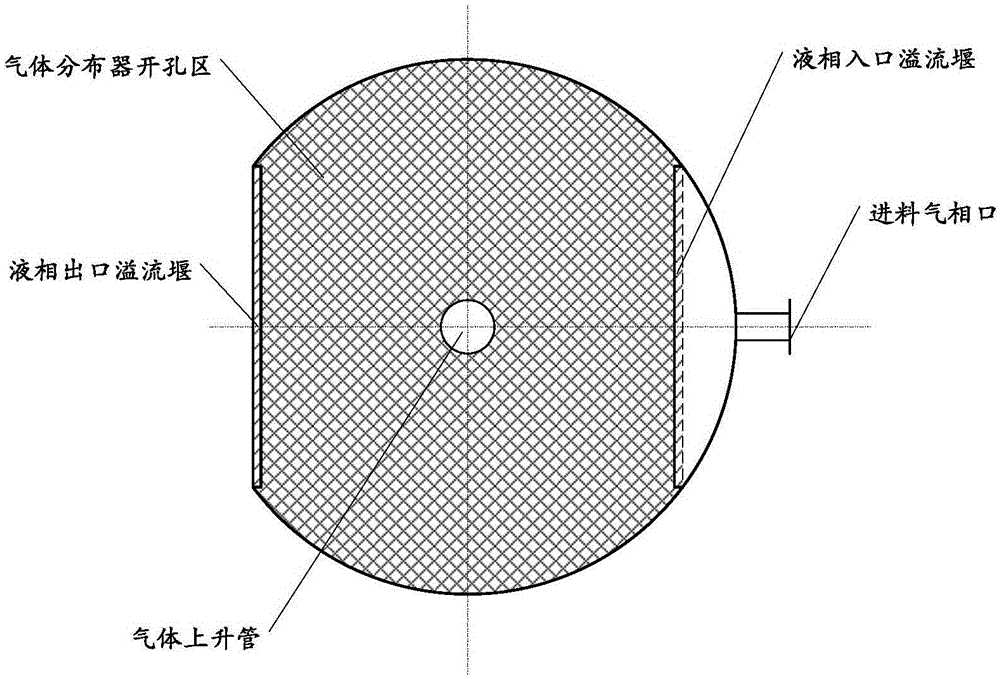

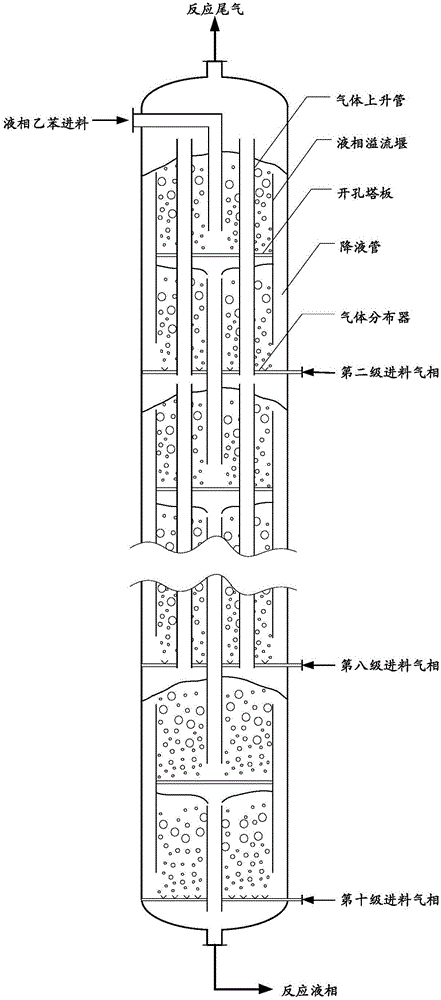

The invention discloses a method for preparing an ethylbenzene hydroperoxide through oxidation of ethylbenzene. A multistage oxidation reactor is adopted. A liquid-phase ethylbenzene reactor flows into the multistage oxidation reactor step by step for gradual oxidation to produce an oxidized mixture containing ethylbenzene hydroperoxide. An oxygen-containing gas is blown into the multistage oxidation and taken as an oxidant. Through optimized multistage reaction technology, the problem of a horizontal reactor in the prior art can be overcome, backmixing of a liquid phase is improved, selectivity of the ethylbenzene hydroperoxide which is a target product is improved, and the oxidation efficiency of ethylbenzene is increased. The security and stability of an oxidation reaction of liquid ethylbenzene in an actual operation are ensured, and the economic benefit of the apparatus is maximized.

Owner:WANHUA CHEM GRP CO LTD

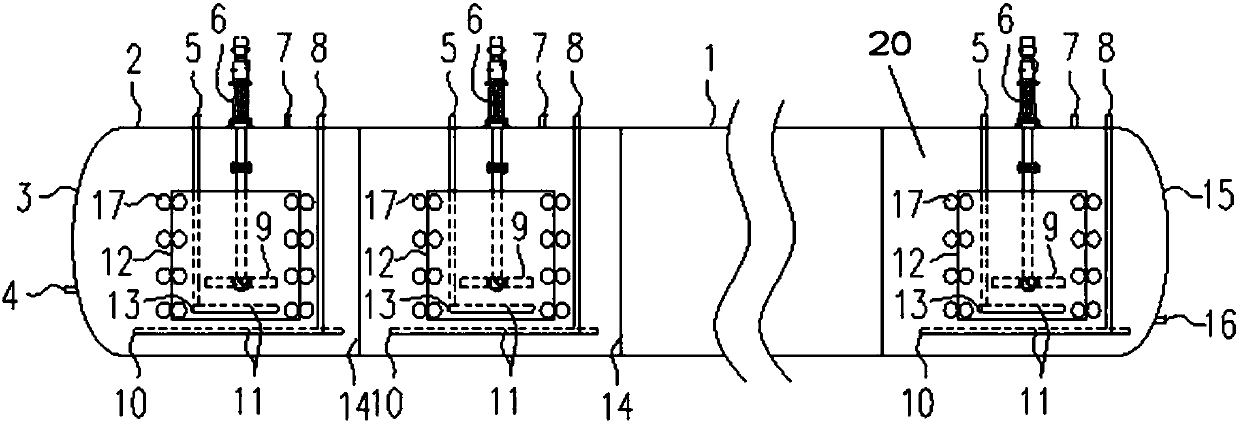

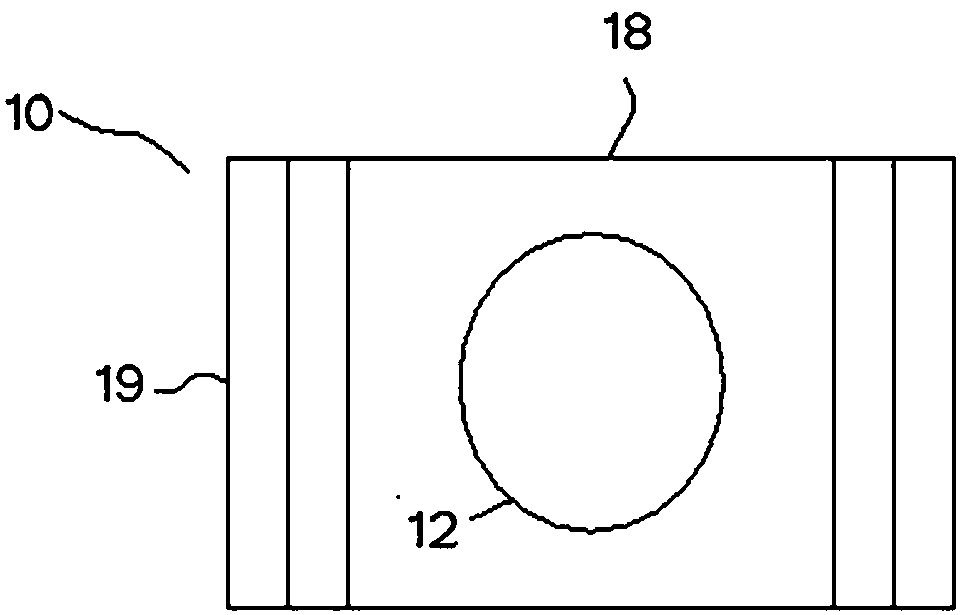

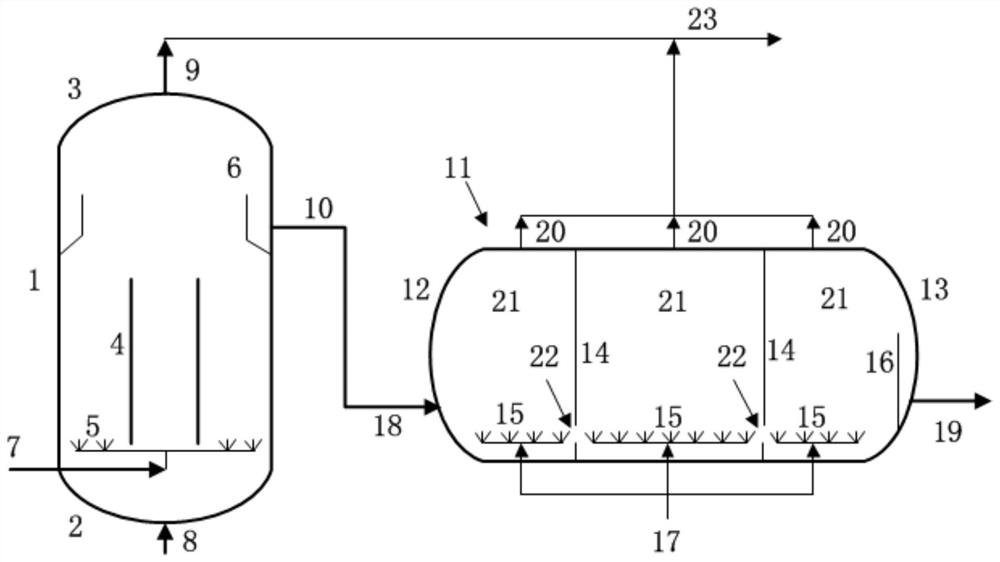

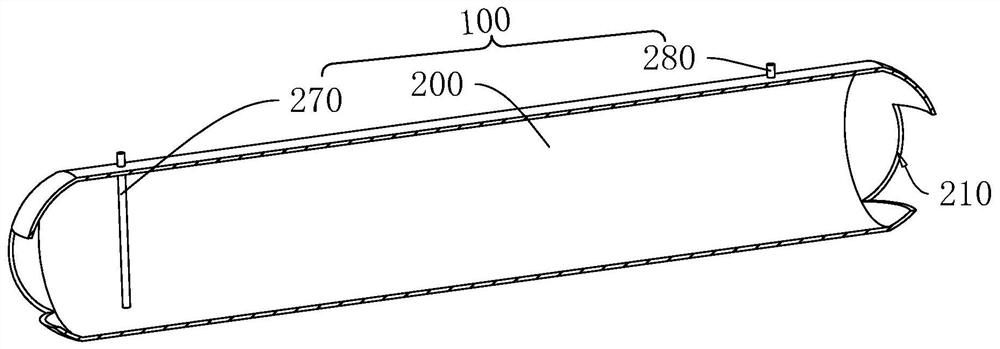

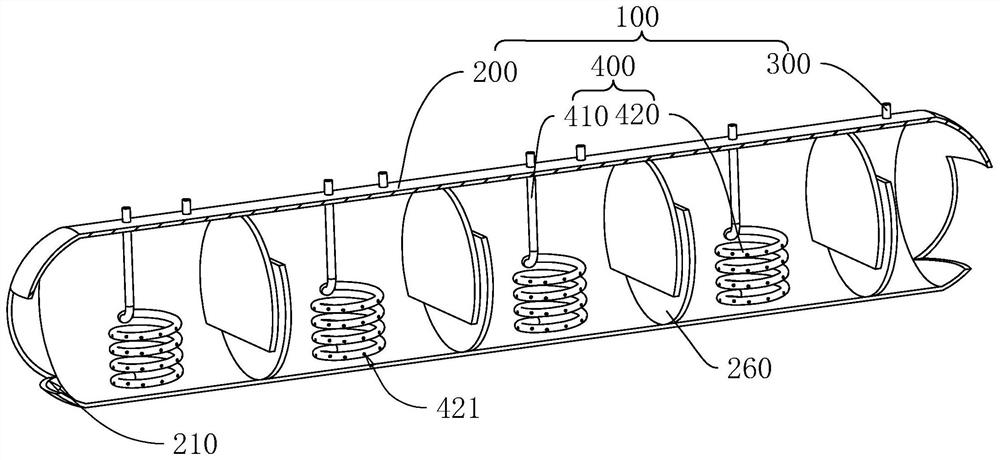

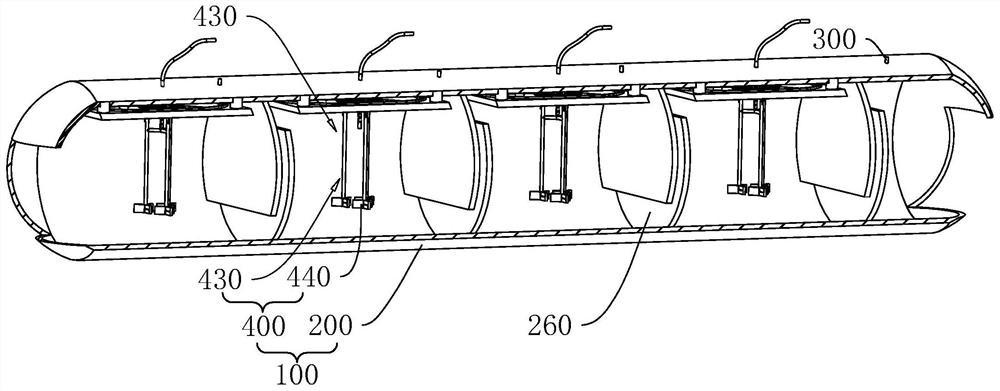

Multistage horizontal stirred air-lift reactor for preparing EBHP and application thereof

ActiveCN107930555AImproves gas distribution uniformityOperational securityOrganic compound preparationChemical/physical/physico-chemical stationary reactorsEthylbenzene hydroperoxideProcess engineering

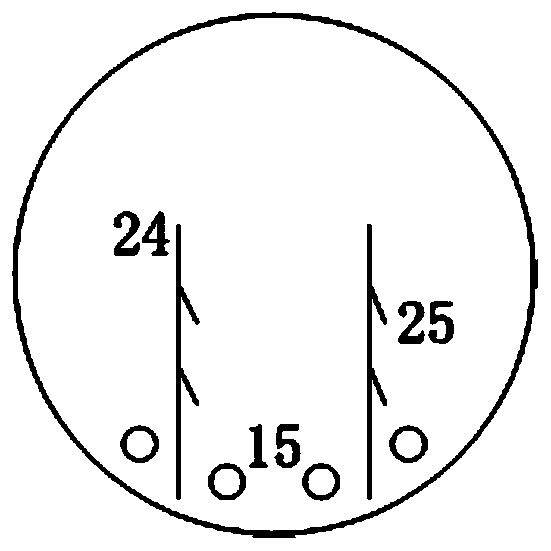

The invention discloses a multistage horizontal stirred air-lift reactor and application of the multistage horizontal stirred air-lift reactor in preparing EBHP. The reactor is of a horizontal tube structure, and comprises a liquid-phase inlet formed in one end and a liquid-phase outlet formed in an opposite end, and a plurality of partition plates arranged at intervals in the longitudinal direction in the reactor, and a liquid-phase channel is arranged between adjacent reaction compartments; an exhaust port is formed in the top of each reaction compartment, and a flow guide tube and a stirring device are arranged in the middle of the each reaction compartment; the flow guide tube is through in a vertical direction, a stirring part of the stirring device is arranged in the flow guide tube;a first gas distributor and a second gas distributor are further arranged in each reaction compartment, the first gas distributor is arranged outside the flow guide tube, and the second gas distributor is arranged inside the flow guide tube. By adopting the device, the uniformity of gas distribution in the reactor is effectively improved, so that the reactor is safer and more reliable to operatewhen the gas flow rate is small, and the flexibility of the device in adapting to market changes is improved.

Owner:WANHUA CHEM GRP CO LTD

Oxidative desulfurization using a titanium(IV) catalyst and organohydroperoxides

ActiveUS8283498B2Organic chemistryOrganic compound preparationEthylbenzene hydroperoxideHydrodesulfurization

Owner:AUTERRA INC

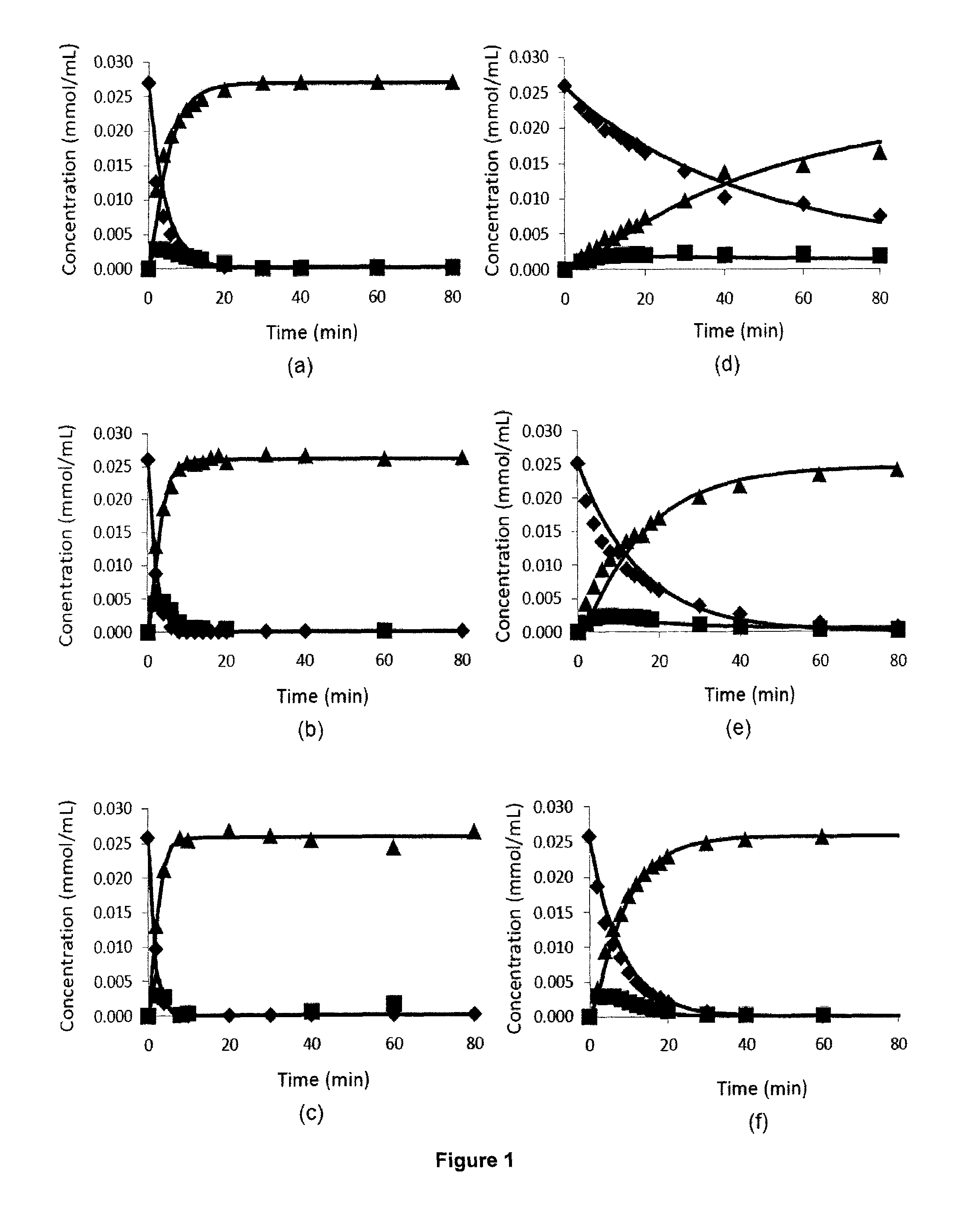

Process for the liquid phase oxidation of ethylbenzene into ethylbenzene hydroperoxide

InactiveUS8017812B2Reduce oxidationOrganic compound preparationPeroxy compound preparationEthylbenzene hydroperoxideOrganic chemistry

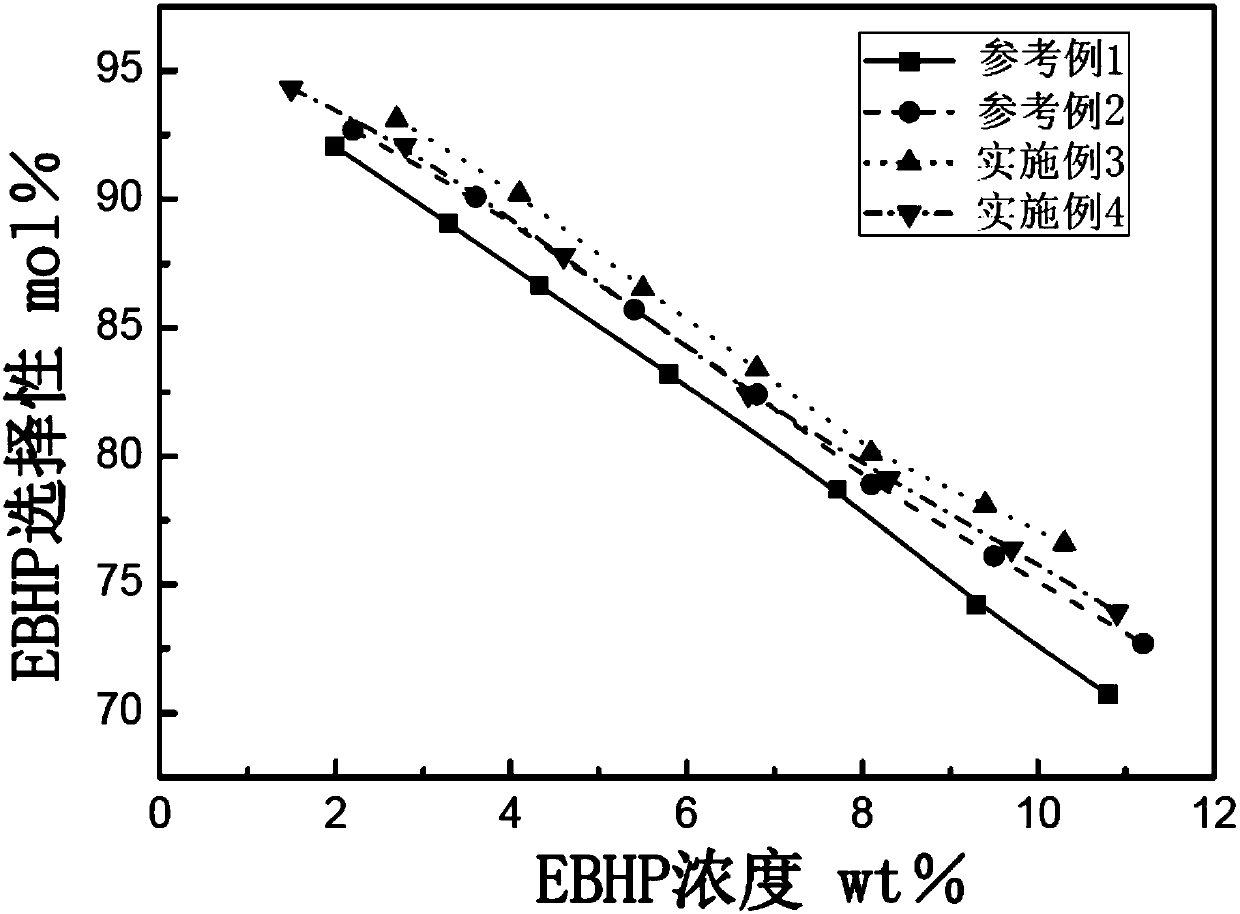

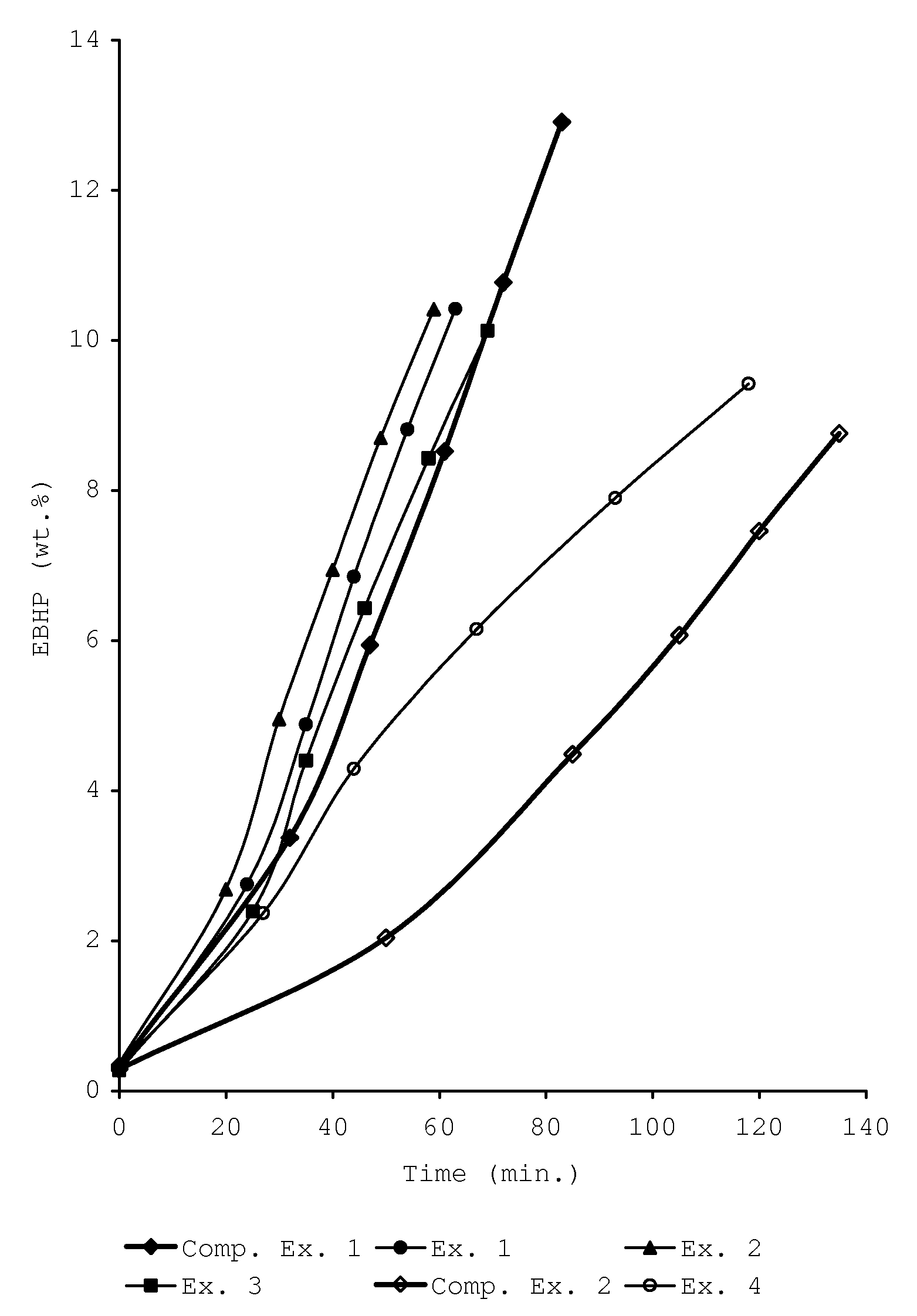

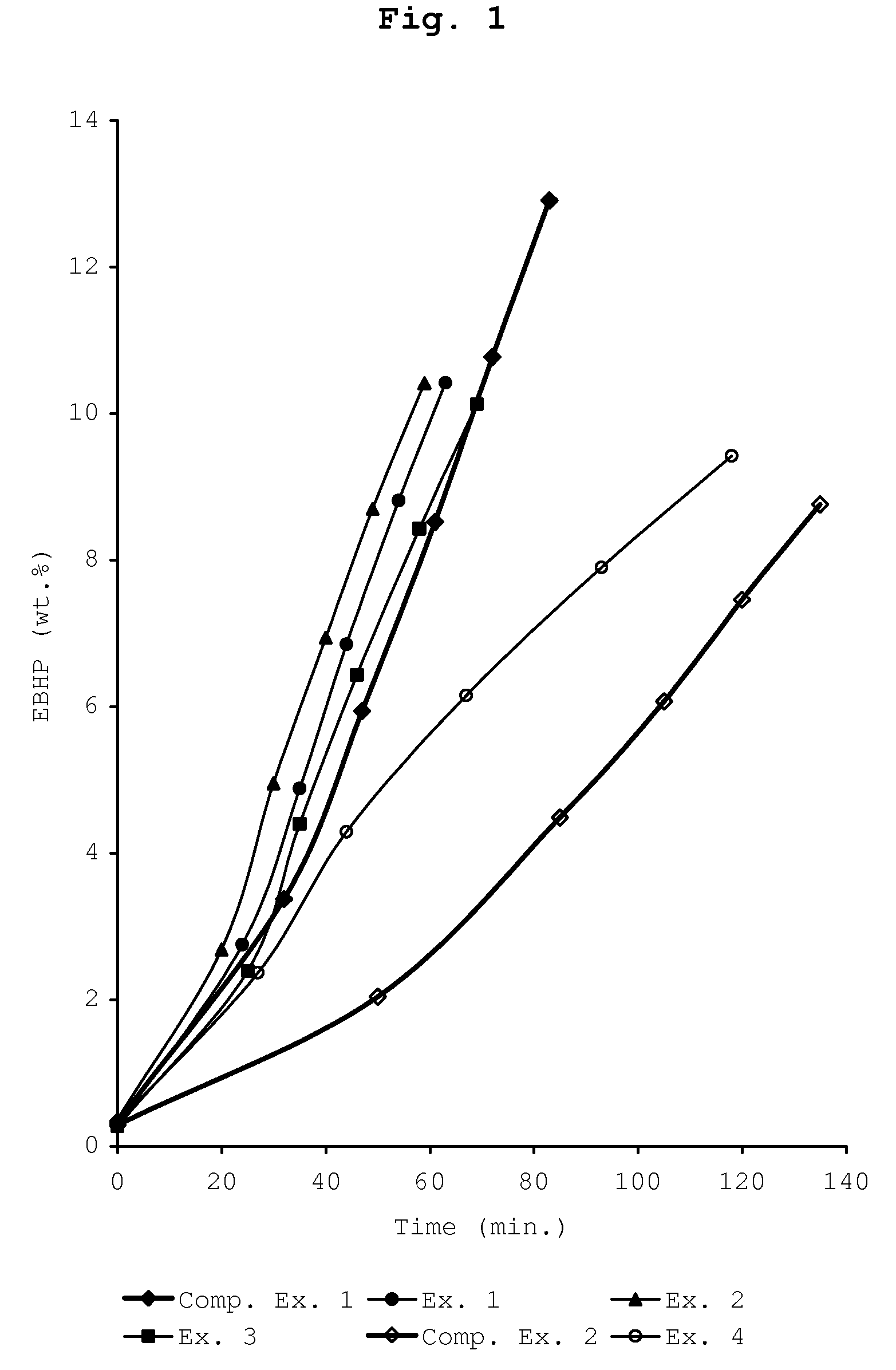

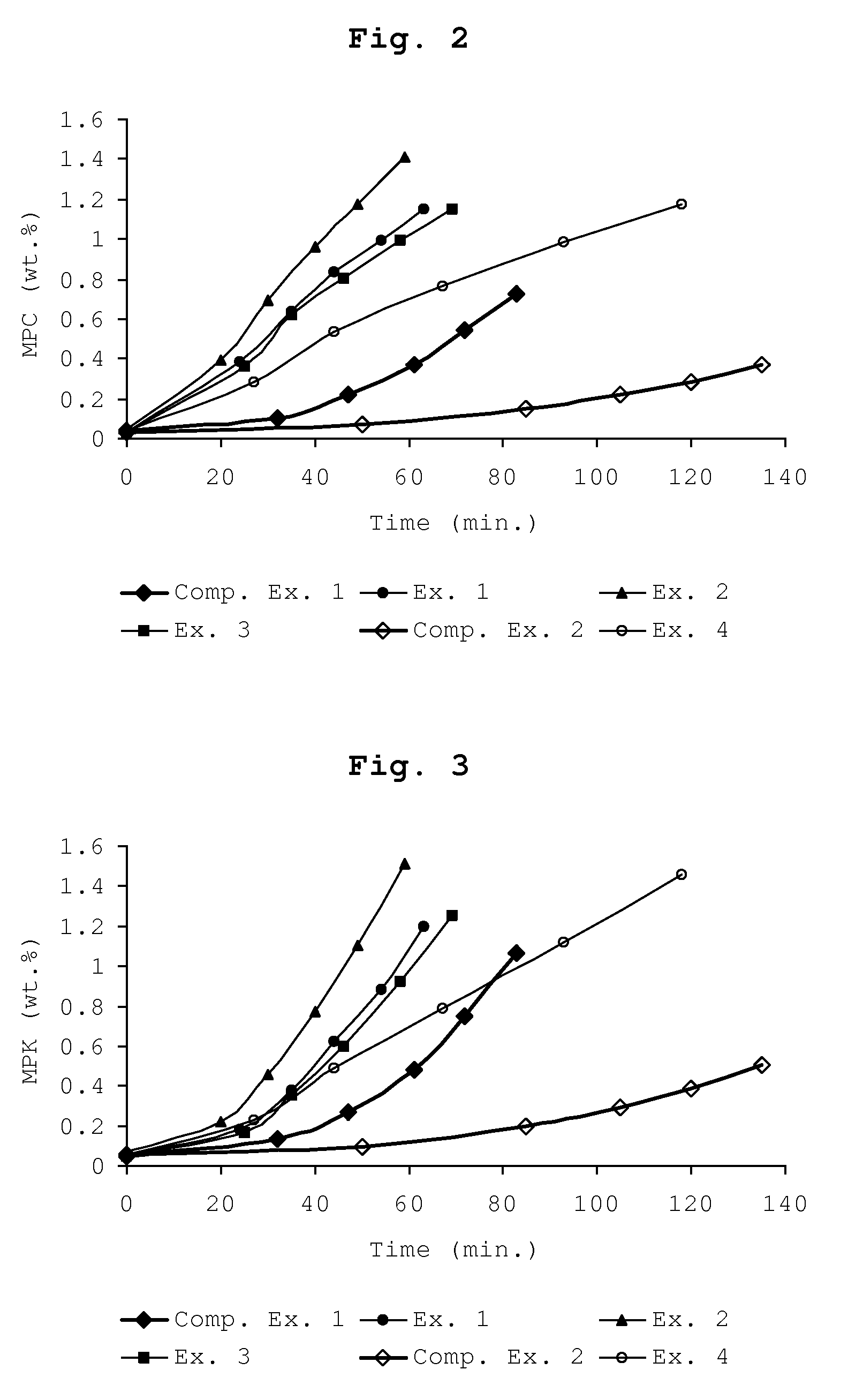

The invention relates to a process for the liquid phase oxidation of ethylbenzene into ethylbenzene hydroperoxide, wherein the ethylbenzene hydroperoxide concentration is kept below 20 wt. % on the basis of the total weight of the reaction mixture, and wherein styrene and / or a styrene derivative is fed to the ethylbenzene. The concentration of said styrene and / or a styrene derivative may be from 0.01 to 5.0 wt. %.

Owner:SHELL OIL CO

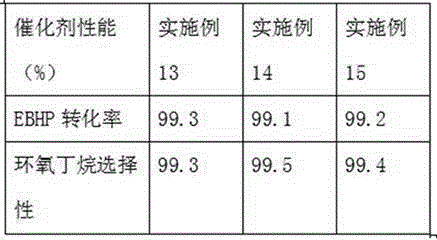

Method for producing epoxybutane

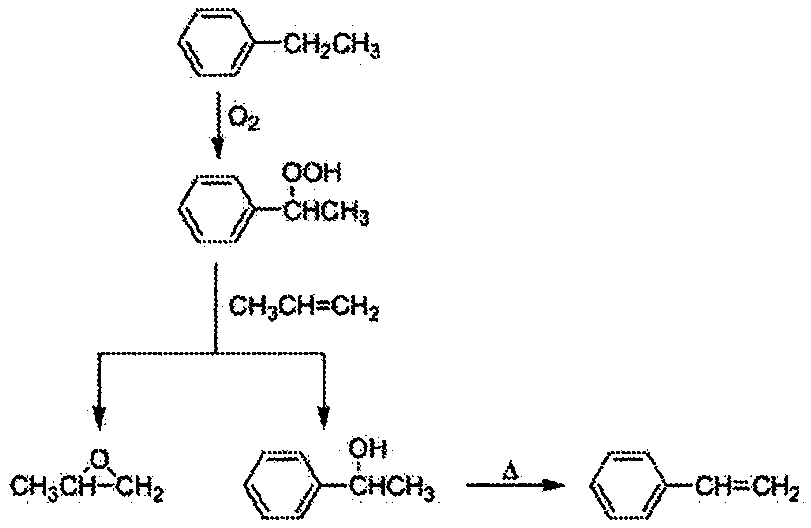

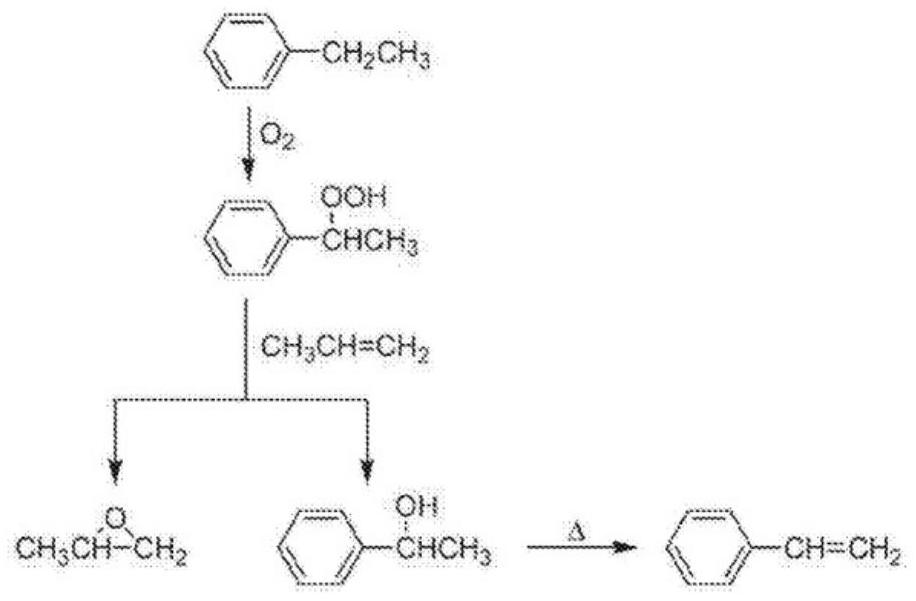

ActiveCN105218485AGood technical and economic effectImprove technical effectHydrocarbon from oxygen organic compoundsButeneEthylbenzene hydroperoxide

The invention relates to an epoxybutane production method to mainly solve the problems of large amount of wastewater and waste residues, severe pollution and strong apparatus corrosion existing in the prior art. The method comprises the following steps: 1, carrying out a peroxidation reaction on ethylbenzene and air to obtain an ethylbenzene hydroperoxide oxidation solution; 2, carrying out an epoxidation reaction on the ethylbenzene hydroperoxide oxidation solution and butylene under the action of a catalyst under liquid phase conditions to generate epoxybutane, alpha-methylbenzyl alcohol and acetophenone; 3, dehydrating alpha-methylbenzyl alcohol to generate styrene; and 4, carrying out a hydrogenation reaction on acetophenone and hydrogen to generate alpha-methylbenzylalcohol, returning the generated alpha-methylbenzylalcohol to step 3, and hydrogenating the returned alpha-methylbenzylalcohol and the alpha-methylbenzylalcohol generated in step 2 to generate styrene. The method adopting the above technical scheme well solves the problems, can be used in industrial production for preparation of epoxybutane and combined production of styrene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing ethylbenzene hydroperoxide by virtue of ethylbenzene liquid phase and preparation method of epoxypropane

ActiveCN109942470AActive influenceAvoid influenceOrganic compound preparationBulk chemical productionEthylbenzene hydroperoxideOxygen

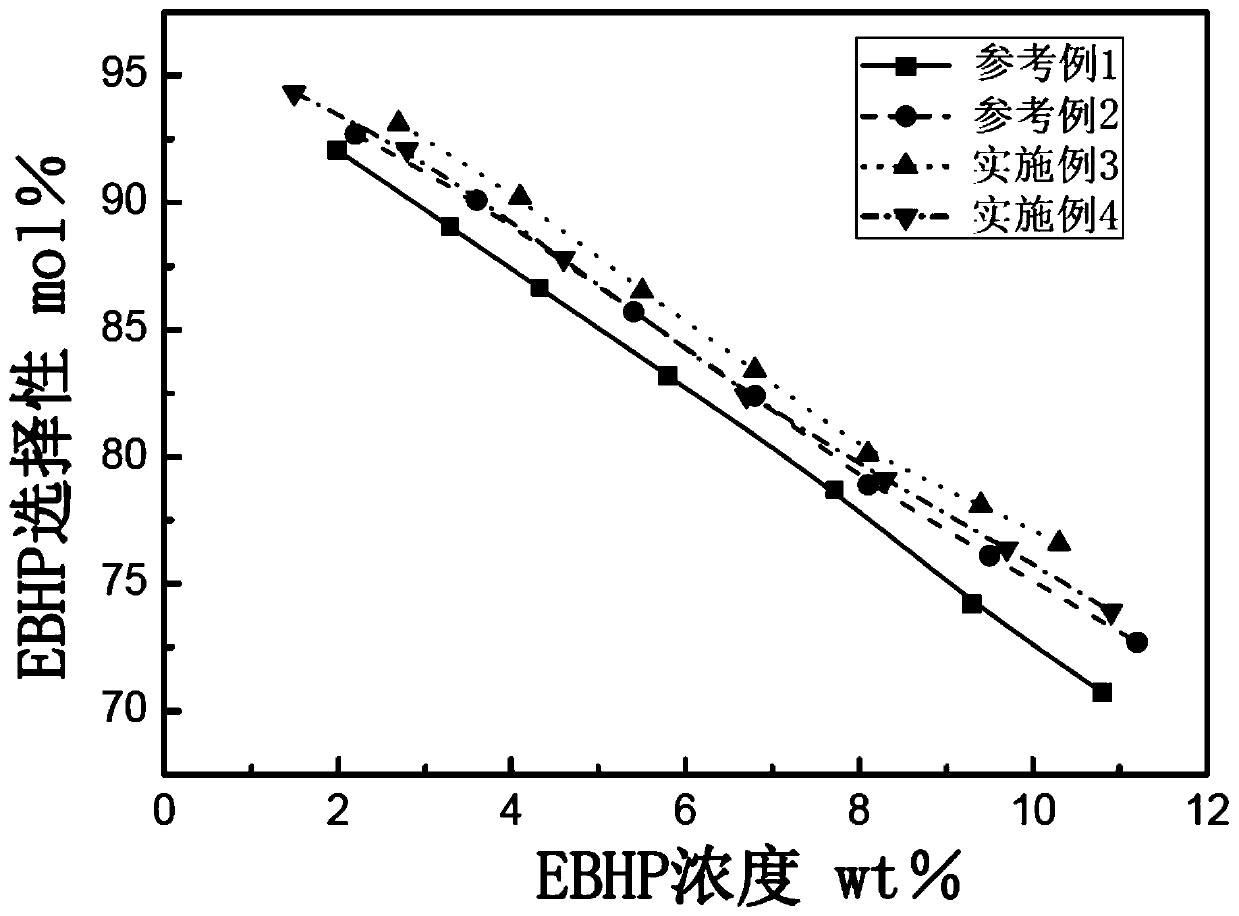

The invention relates to a method for preparing ethylbenzene hydroperoxide by virtue of an ethylbenzene liquid phase and a preparation method of epoxypropane. According to the method, by adding a small amount of organic alkali substances, the peroxidation reaction between ethylbenzene gas containing oxygen molecules is promoted. According to the method, the selectivity of a target product can be effectively improved, and the activity of a subsequent epoxidation catalyst is not influenced by the added organic alkali substances.

Owner:WANHUA CHEM GRP CO LTD

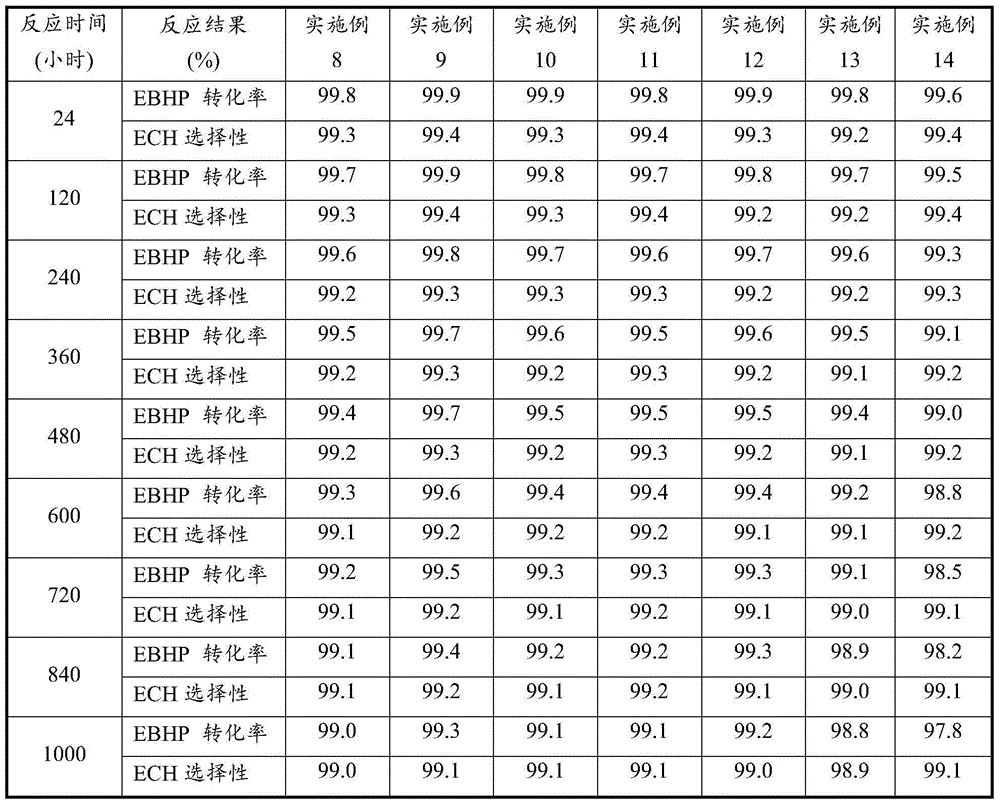

Production method for epichlorohydrin

InactiveCN105272945AFree from pollutionHigh selectivityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsReaction temperatureSolvent

The invention relates to a production method for epichlorohydrin. The method mainly solves the problems of large amounts of waste water and waste residues, serious pollution and strong corrosiveness to equipment in the prior art. A technical scheme of the invention adopts the production method which comprises the following steps: with chloropropene and ethylbenzene hydroperoxide as raw materials and ethylbenzene as a solvent, subjecting the raw materials and a titanium-contained porous silicon dioxide catalyst to contact reaction so as to obtain epichlorohydrin and alpha-methylbenzyl alcohol under the conditions that reaction temperature is 25 to 200 DEG C; reaction absolute pressure is 0.1 to 8.0 MPa; a molar ratio of chloropropene to ethylbenzene hydroperoxide is 1 to 15; and weight-space velocity of ethylbenzene hydroperoxide is 0.01 to 20 h<-1>. Thus, the problem is well solved, and the method can be applied in industrial production of epichlorohydrin.

Owner:CHINA PETROLEUM & CHEM CORP +1

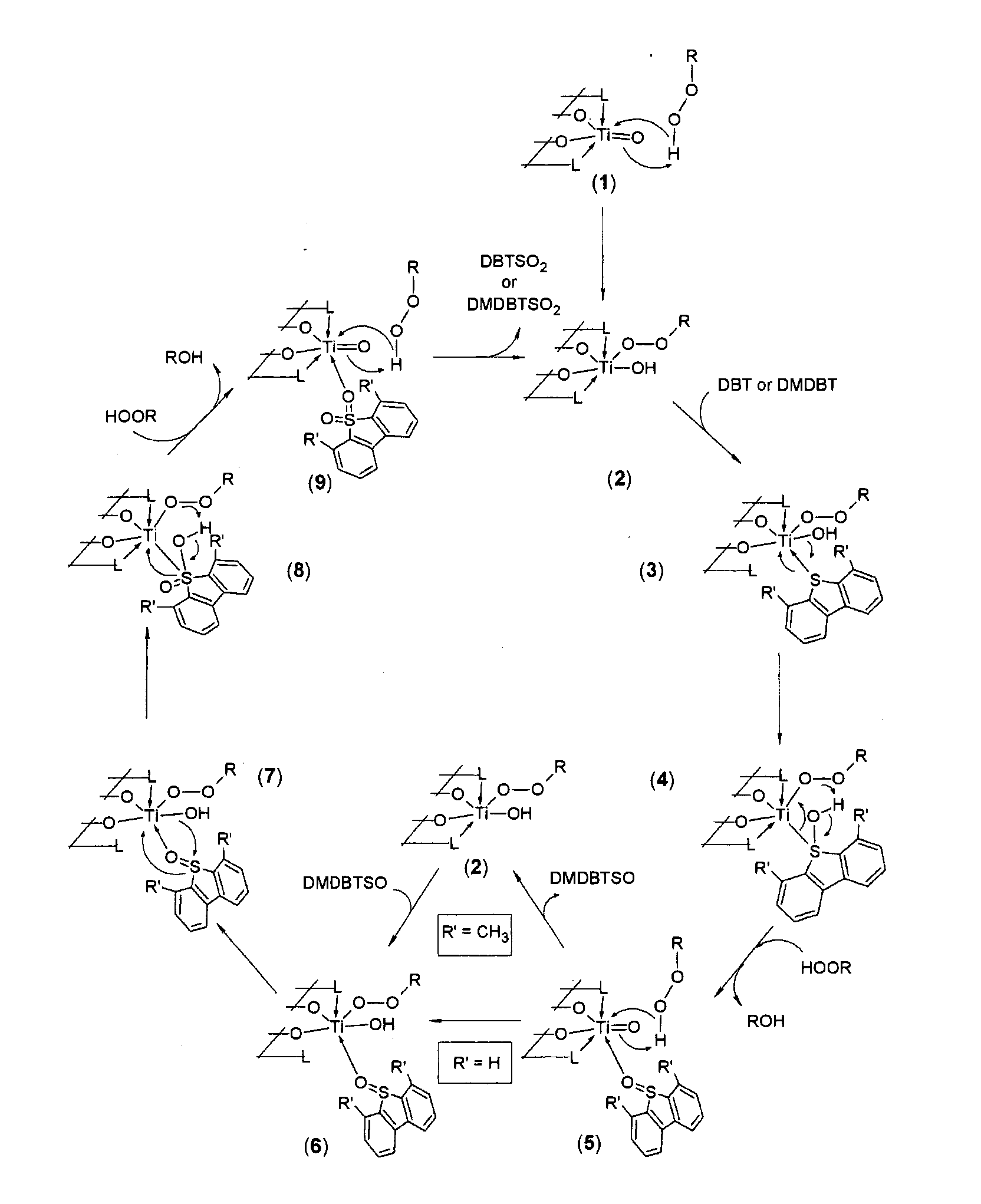

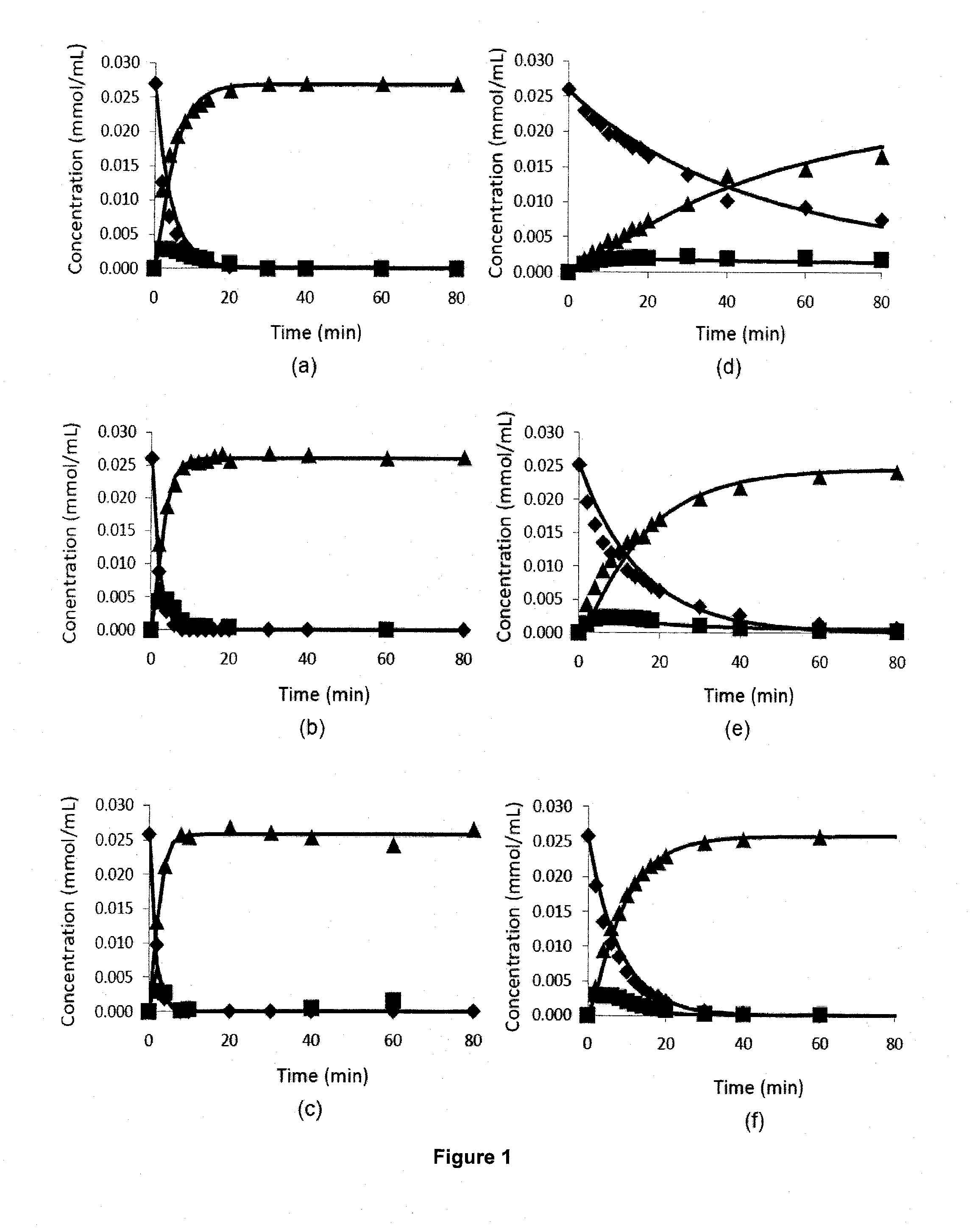

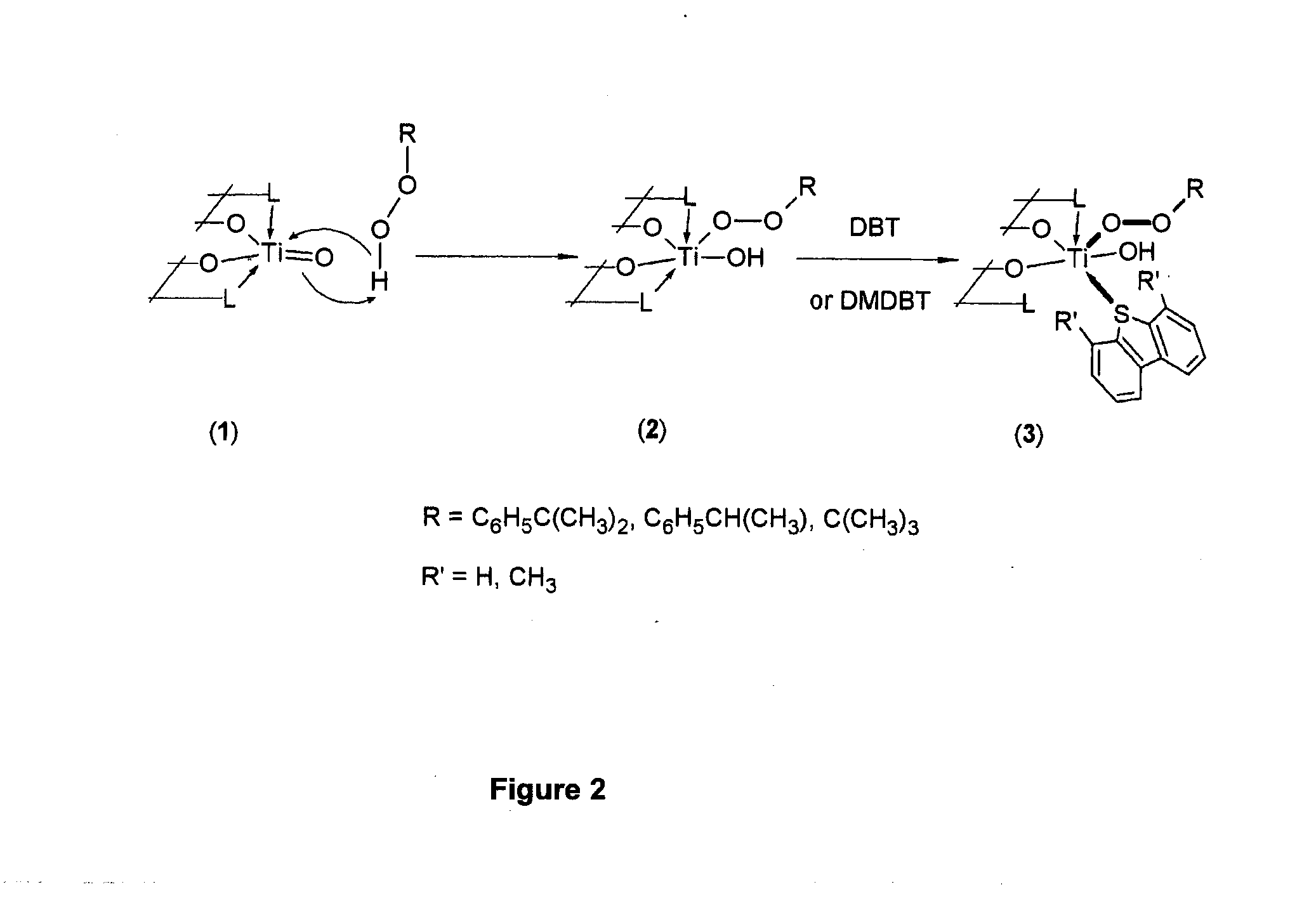

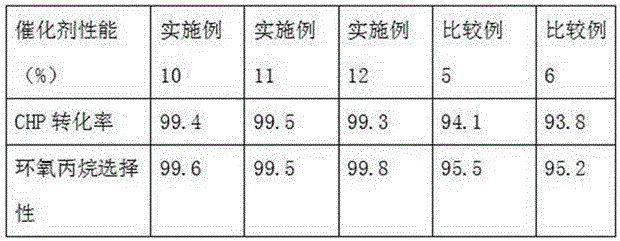

Oxidative desulfurization using a titanium(IV) catalyst and organohydroperoxides

ActiveUS20120022272A1Valid choiceOrganic chemistryOrganic compound preparationEthylbenzene hydroperoxideHydrodesulfurization

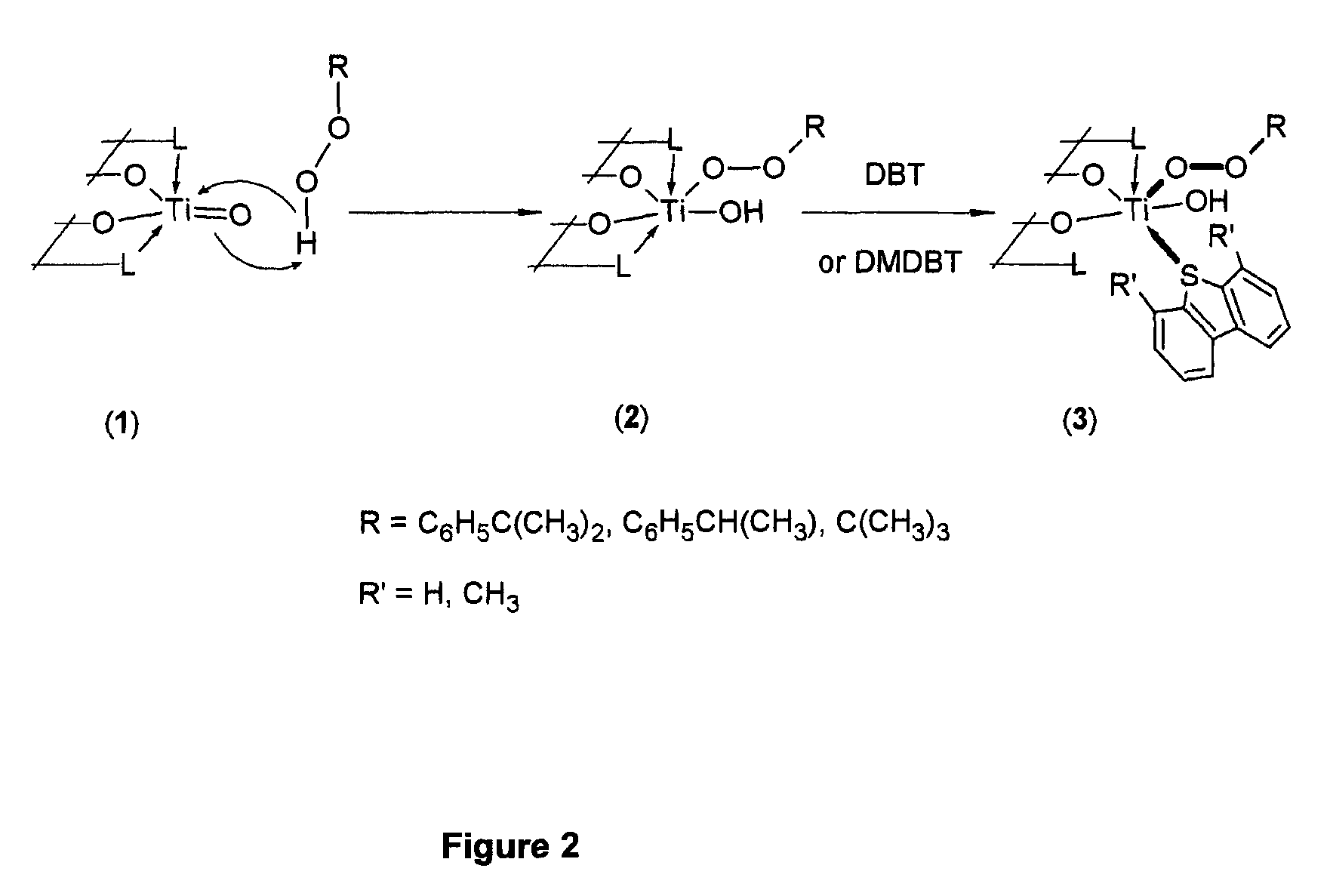

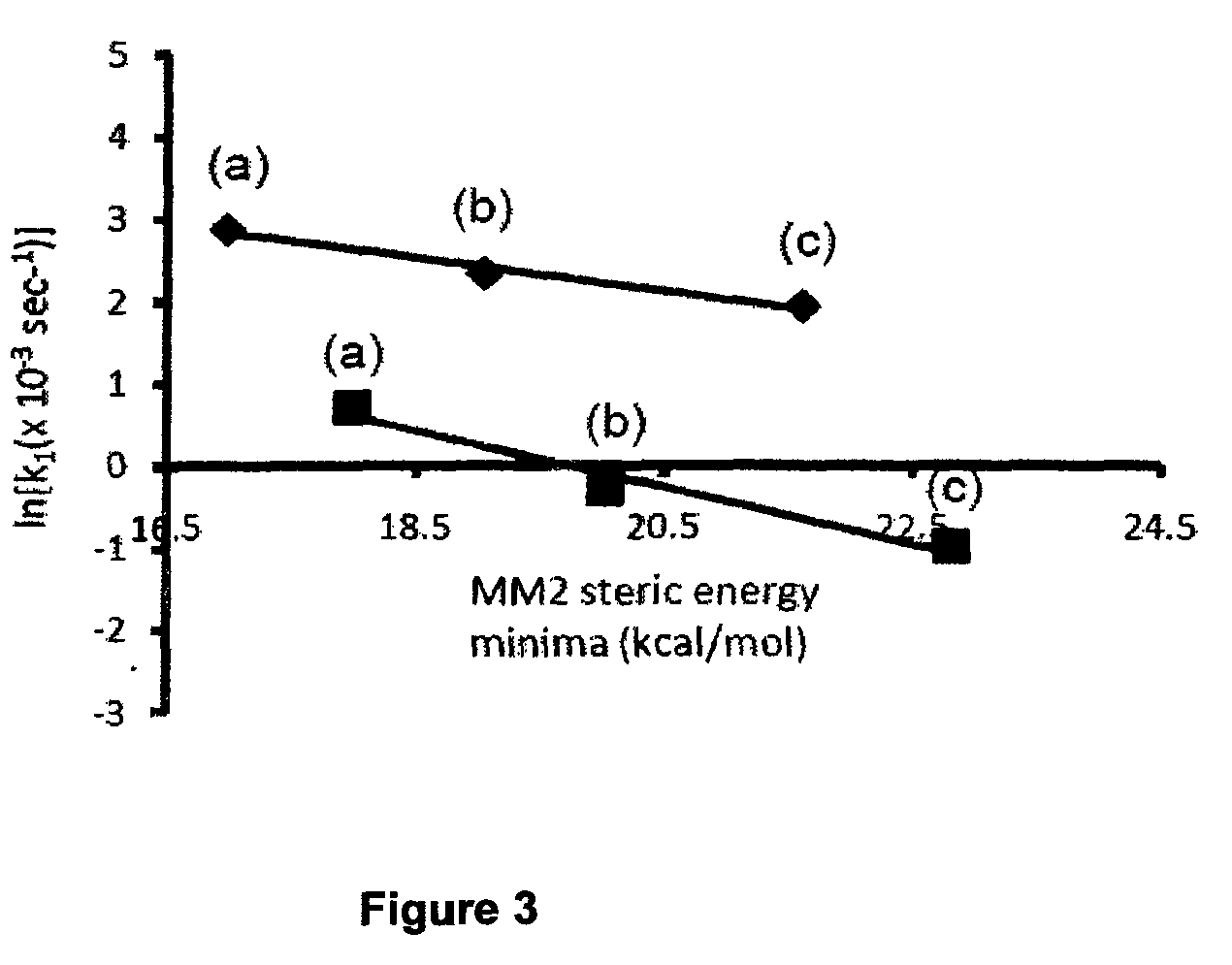

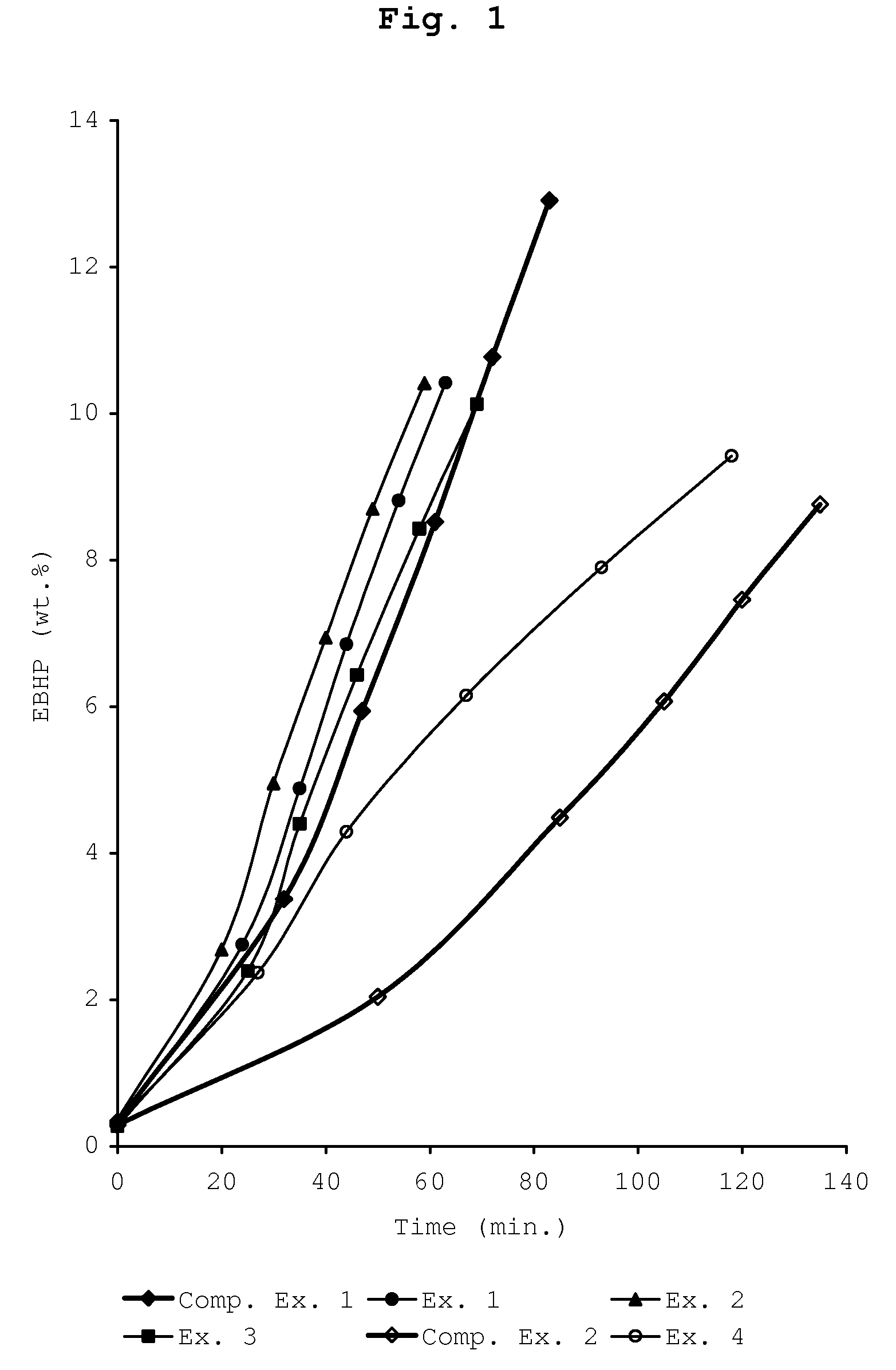

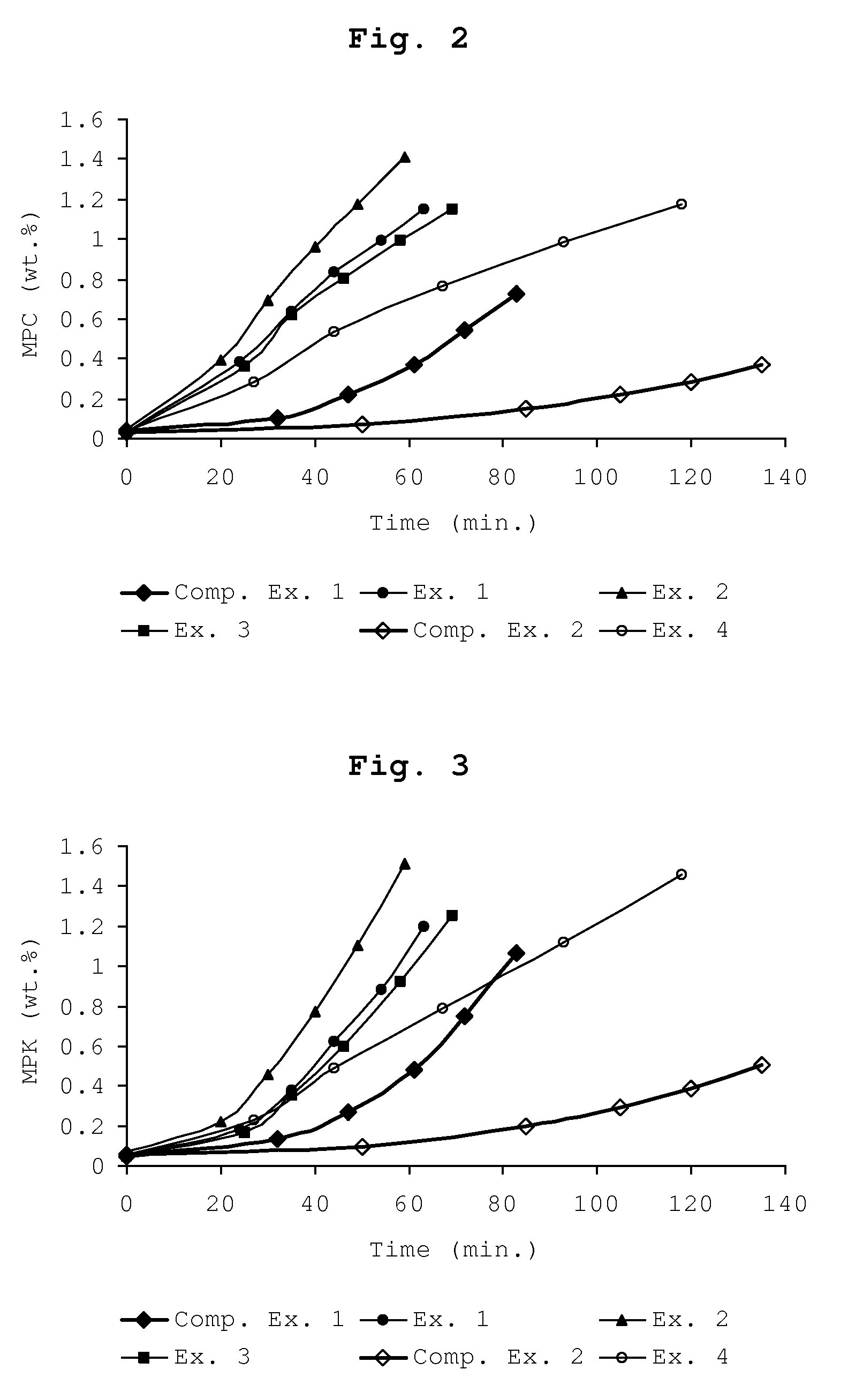

Oxidative desulfurization (ODS) is an attractive alternative to hydrodesulfurization (HDS) technology due to its lower energy requirement for the removal of refractory sulfur species, such as dibenzothiophene (DBT), from heavier petroleum streams. Diesel containing DBT may be oxidized using a heterogeneous titanium(IV) catalyst and organohydroperoxide oxidant, such as tert-butyl hydroperoxide (TBHP), cumyl hydroperoxide (CHP) and / or ethylbenzene hydroperoxide (EBHP), which proves effective for the selective oxidation and removal of refractory sulfur compounds from diesel fuel.

Owner:AUTERRA INC

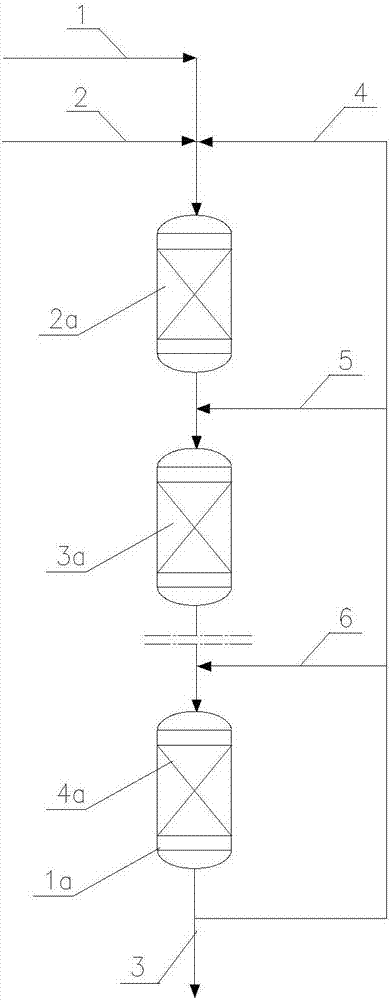

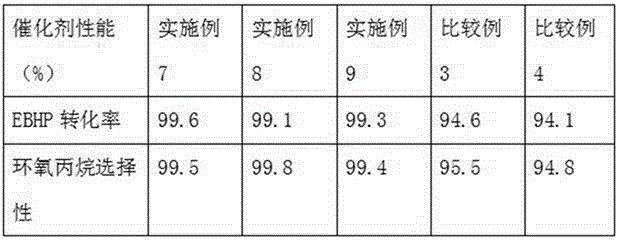

Method for preparing epoxy propane from ethylbenzene hydroperoxide and propylene

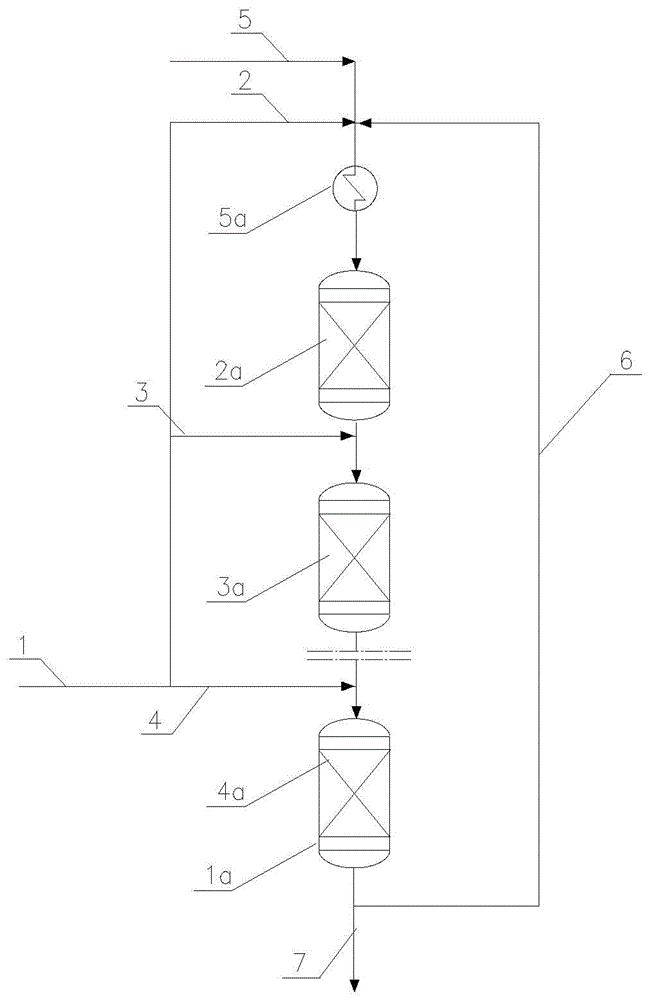

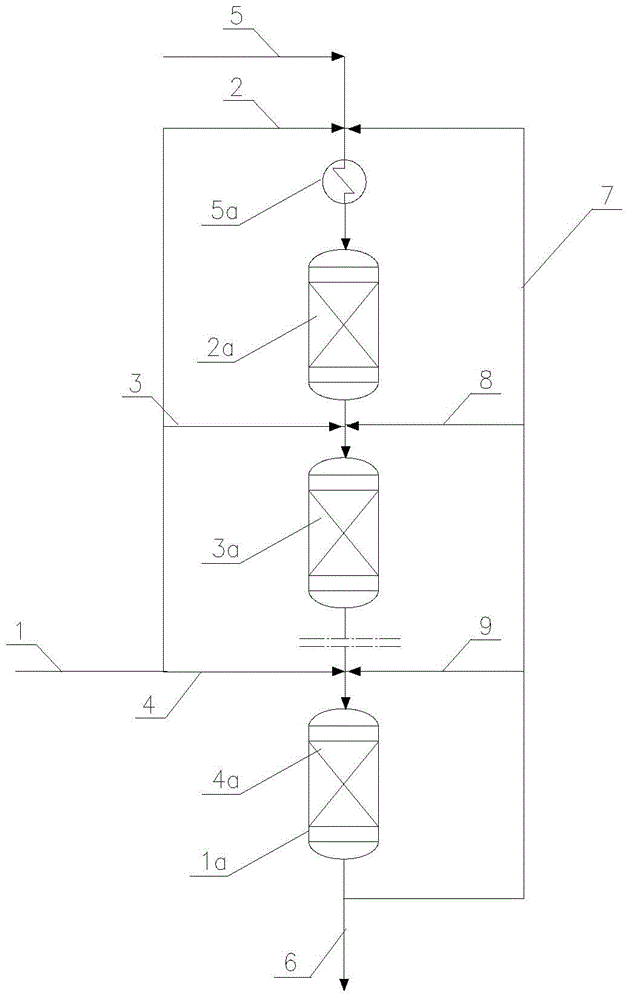

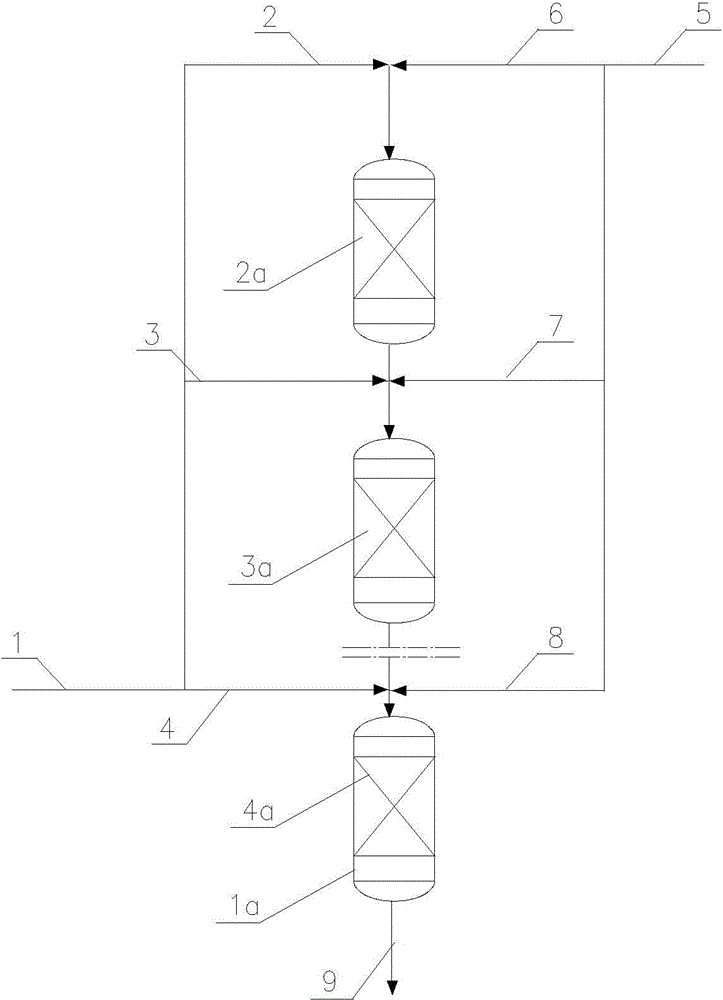

InactiveCN105272943AControl reaction temperatureReduce the cycle rateOrganic chemistryEthylbenzene hydroperoxideReaction temperature

The invention relates to a method for preparing epoxy propane from ethylbenzene hydroperoxide and propylene, and is used for mainly solving the problems in the prior art that reaction temperature rising is higher and higher molar ratio of propylene to ethylbenzene hydroperoxide is needed for maintaining higher reaction efficiency. The problems are better solved through adopting the technical schemes that raw materials of ethylbenzene hydroperoxide and liquid propylene go into a multistage adiabatic reactor, and under conditions of the reaction temperature of 15-160 DEG C, the pressure of 1.0-12.0 MPa and the total molar ratio of propylene to ethylbenzene hydroperoxide of 1-20, the raw materials make contact with a Ti-silica catalyst and subjected to an epoxidation reaction to generate epoxy propane, wherein the raw material ethylbenzene hydroperoxide goes into catalyst bed layers of the multistage adiabatic reactor in a sectionalized manner, and a part of epoxidation reaction products containing epoxy propane circulate to an inlet of the reactor. The method can be used in industrial production of preparation of epoxy propane through epoxidation of ethylbenzene hydroperoxide and propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Epoxidation cyclic method for preparing epoxy propane from ethylbenzene hydroperoxide and propylene

InactiveCN105272938AControl reaction temperatureReduce the cycle rateOrganic chemistryChemical recyclingCyclic processReaction temperature

The invention relates to an epoxidation cyclic process for preparing epoxy propane from ethylbenzene hydroperoxide and propylene, and is used for mainly solving the problems in the prior art that reaction temperature rising is higher and higher molar ratio of propylene to ethylbenzene hydroperoxide is needed for maintaining higher reaction efficiency. The problems are better solved through adopting the technical schemes that a raw material ethylbenzene hydroperoxide sectionally goes into at least two series-connection adiabatic reactors and a raw material liquid propylene goes into at least two series-connection adiabatic reactors, and under conditions of the reaction temperature of 15-160 DEG C, the pressure of 1.0-12.0 MPa and the total molar ratio of propylene to ethylbenzene hydroperoxide of 1-20, the raw materials make contact with a Ti-silica catalyst and subjected to an epoxidation reaction to generate epoxy propane, wherein a part of epoxidation reaction products containing epoxy propane circulate to catalyst bed layers of the reactors. The method can be used in industrial production of preparation of epoxy propane through epoxidation of ethylbenzene hydroperoxide and propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing epoxy propane through epoxidation of ethylbenzene hydroperoxide and propylene

InactiveCN105272944AControl reaction temperatureReduce the cycle rateOrganic chemistryEthylbenzene hydroperoxideReaction temperature

The invention relates to a method for preparing epoxy propane through epoxidation of ethylbenzene hydroperoxide and propylene, and is used for mainly solving the problems in the prior art that reaction temperature rising is higher and higher molar ratio of propylene to ethylbenzene hydroperoxide is needed for maintaining higher reaction efficiency. The problems are better solved through adopting the technical schemes that raw materials of ethylbenzene hydroperoxide and liquid propylene go into a multistage adiabatic reactor, and under conditions of the reaction temperature of 15-160 DEG C, the pressure of 1.0-12.0 MPa and the total molar ratio of propylene to ethylbenzene hydroperoxide of 1-20, the raw materials make contact with a Ti-silica catalyst and subjected to an epoxidation reaction to generate epoxy propane, wherein all or a part of the raw material propylene goes into an inlet of the multistage reactor, and the raw material ethylbenzene hydroperoxide sectionally goes into catalyst bed layers of the multistage adiabatic reactor in a sectionalized manner. The method can be used in industrial production of preparation of epoxy propane through epoxidation of ethylbenzene hydroperoxide and propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Titanium-containing silicon oxide catalyst

InactiveUS20020037807A1Organic chemistryMolecular sieve catalystsEthylbenzene hydroperoxideSilicon oxide

A titanium-containing silicon oxide catalyst satisfying all of the following conditions (1) to (4): (1): an average pore size of 10 Å or more, (2): a pore size of 90% or more of the total pore volume of 5 to 200 Å, (3): a specific pore volume of 0.2 cm3 / g or more, and (4): a quarternary ammonium ion represented by the following general formula (I) is used as a template and then said template is removed by solvent extraction operation;<paragraph lvl="0"><in-line-formula>[NR1R2R3R4]+ (I)< / in-line-formula>wherein, R1 represents a linear or branched hydrocarbon chain having 2 to 36 carbon atoms, and R2 to R4 represent an alkyl group having 1 to 6 carbon atoms, a method for producing said catalyst, and a method for producing propylene oxide by reacting propylene with a hydroperoxide, except for ethylbenzene hydroperoxide, in the presence of said catalyst.

Owner:SUMITOMO CHEM CO LTD

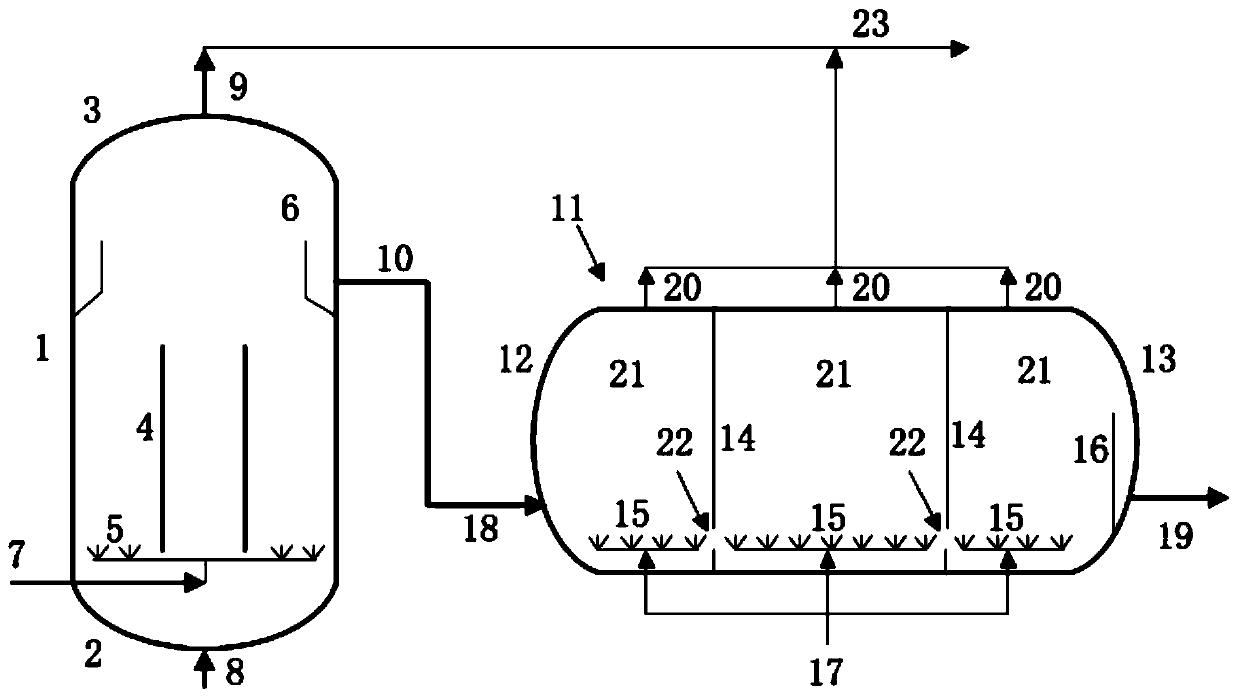

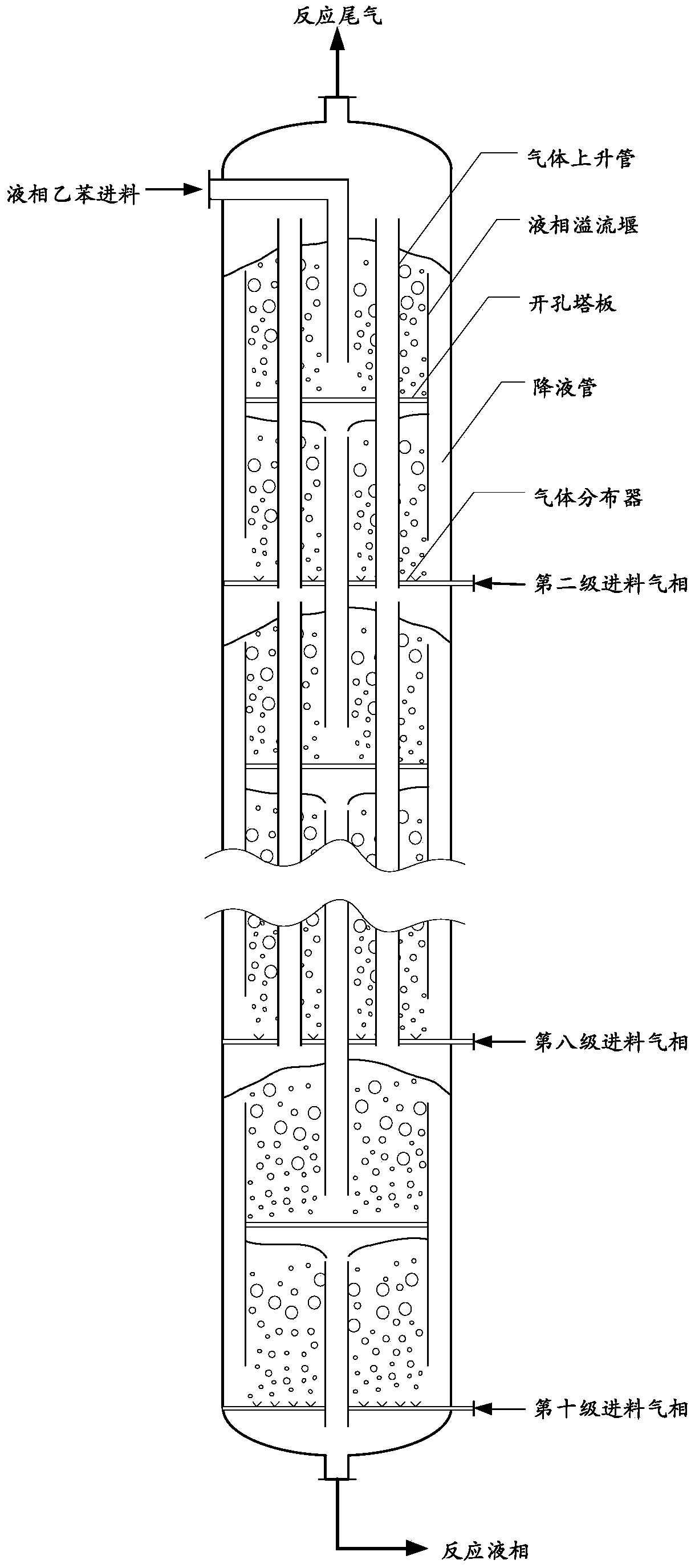

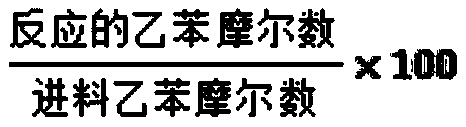

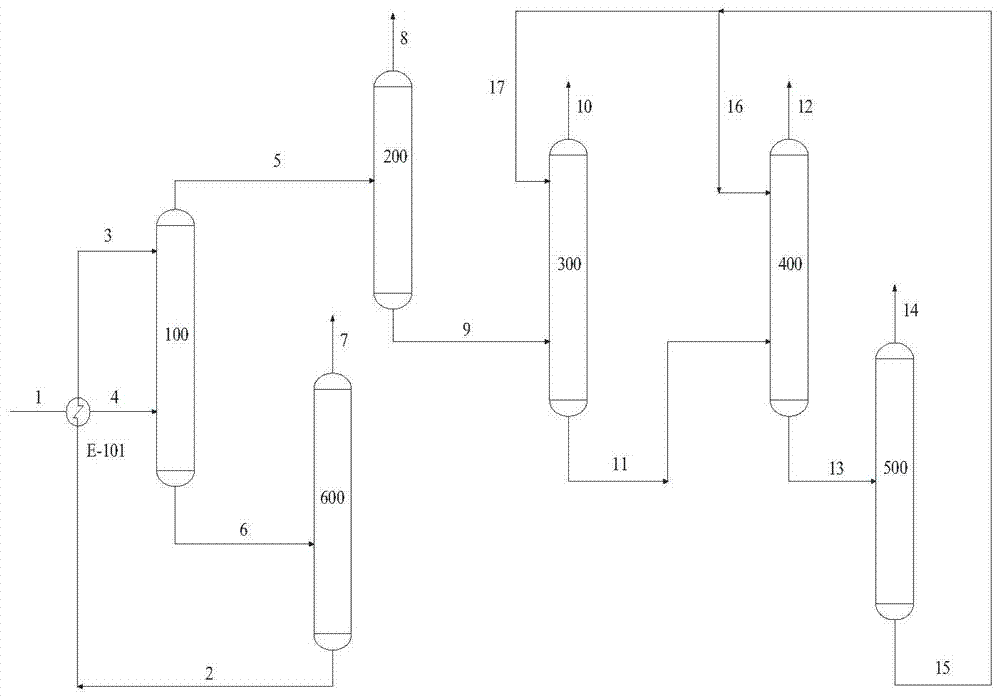

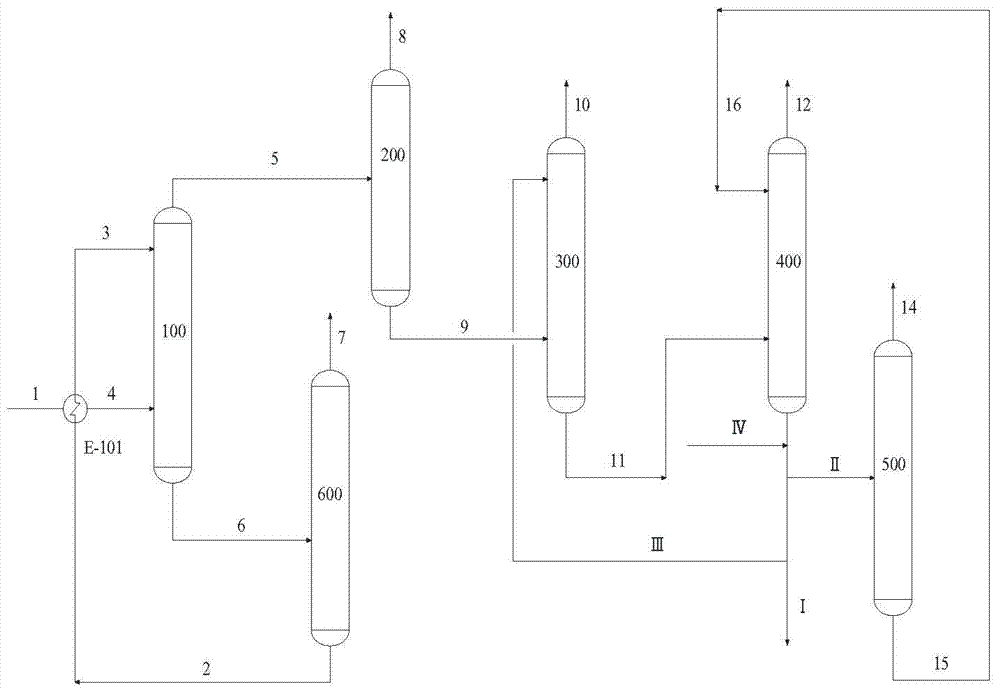

Device and method for oxidizing organic matters

ActiveCN109967022APromote reaction efficiencyGood reaction selectivityLiquid-gas reaction as foam/aerosol/bubblesOrganic compound preparationEthylbenzene hydroperoxideProduct gas

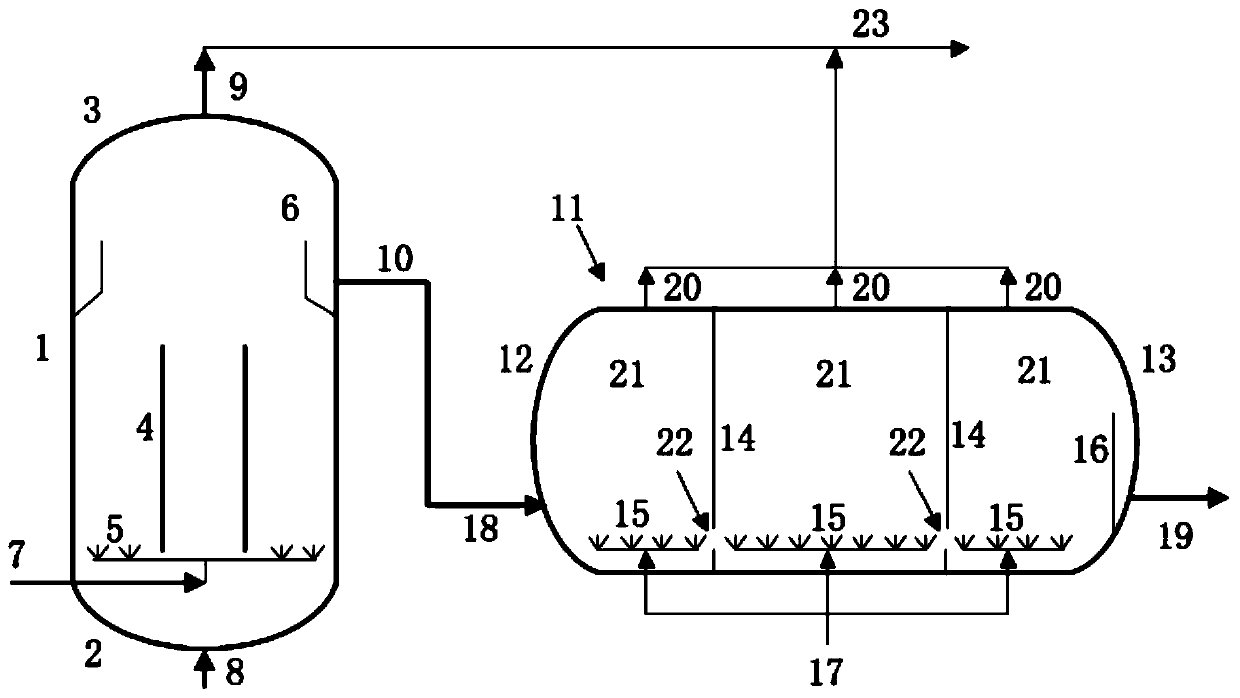

The invention discloses a device and method for oxidizing organic matters, particularly a method for preparing ethylbenzene hydroperoxide by reacting ethylbenzene with an oxygen-containing gas. The device includes a vertical bubbling reactor and a horizontal bubbling reactor connected to a reaction product outlet of the vertical bubbling reactor. The horizontal bubbling reactor is provided with aplurality of reaction compartments arranged along the axial direction inside, with a liquid phase passage being between adjacent reaction compartments. Through ingenious combination of the reactors, organic matter oxidation can be performed under more favorable conditions, thereby improving the production capacity of the device.

Owner:WANHUA CHEM GRP CO LTD

Method for preparing efficient titanium silicalite molecular sieve catalyst

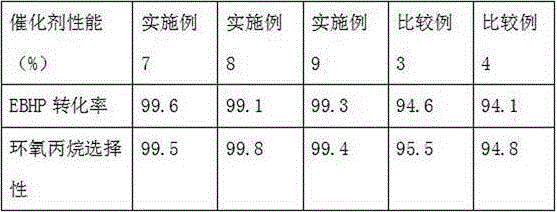

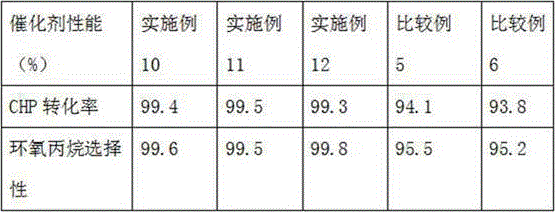

InactiveCN106315608AGood choiceImprove stabilityOrganic chemistryMolecular sieve catalystsCalcinationEthanol

The invention relates to a method for preparing an efficient titanium silicalite molecular sieve catalyst. The method comprises the following steps: mixing and hydrolyzing a mixture composed of a silicon source, a template agent, a mineralizer, water and ethanol according to a volume ratio of 1:1 at normal temperature; slowly adding a mixture of a titanium source and the residual silicon source into the hydrolyzed silicon hydroxide solution while rapidly stirring, and forming gel; transferring the gel into a crystallization kettle for crystallizing; washing, filtering and roasting a crystallized molecular sieve so as to remove the template agent, wherein the calcination temperature is 500-600 DEG C, and the calcination time is 4-6 hours, thereby obtaining the composite porous molecular sieve based catalyst. The catalyst is simple in preparation process and high in production efficiency; moreover, because the molecular sieve structure contains organic functional groups and composite pores with hydrophobic property and carbon deposition resistance, the catalyst is excellent in hydrophobic property and mass transfer performance and high in activity, selectivity and stability, and can be used in the process of producing corresponding epoxides through olefin epoxidation by taking H2O2, ethylbenzene hydroperoxide, isopropylbenzene hydroperoxide, tert-butyl hydroperoxide and the like as oxidizing agents.

Owner:QINGDAO WINCHANCE TECH

Method for improving stability of ethylbenzene hydroperoxide

InactiveCN109180548AAvoid decompositionReduce generationOrganic compound preparationPeroxy compound preparationEthylbenzene hydroperoxideMalonic acid

The invention discloses a method for improving the stability of ethylbenzene hydroperoxide. The method includes the step of addition of malonic acid derivatives and / or succinic acid derivatives duringthe preparation of ethylbenzene hydroperoxide. The method can effectively inhibit decomposition of ethylbenzene hydroperoxide produced by oxidation, is especially suitable for an SMPO process, and isbeneficial to improvement of the stability of the intermediate ethylbenzene hydroperoxide in the process. The method cannot introduce metal cationic sodium or potassium and the like, can reduce scaling problems caused by material entrainment and the like, reduces discharge of phosphorus-containing wastewater, has good environmental protection, and improves the selectivity and yield of the reaction.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Reaction method of ethylbenzene hydrogen peroxide and propylene to produce propylene oxide

ActiveCN105294606BControl reaction temperatureIncrease the proportion of propyleneOrganic chemistryEthylbenzene hydroperoxideReaction temperature

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of method that ethylbenzene oxidation prepares ethylbenzene hydroperoxide

ActiveCN106554298BOrganic compound preparationLiquid-gas reaction processesEthylbenzene hydroperoxideEconomic benefits

The invention discloses a method for preparing ethylbenzene hydroperoxide by oxidizing ethylbenzene. A multi-stage oxidation reactor is adopted, and a liquid-phase ethylbenzene reactant is flowed through the multi-stage oxidation reactor step by step, and is gradually oxidized to generate ethylbenzene rich in ethylbenzene. The oxidation mixture of hydroperoxide, oxygen-containing gas is blown into the multi-stage reactor as oxidant, and through the optimized multi-stage reaction process, the problems of the existing horizontal reactor can be effectively avoided, the liquid phase back-mixing can be effectively improved, and the target product B. The selectivity of benzene hydroperoxide improves the ethylbenzene oxidation efficiency, and at the same time ensures the safety and stability in the actual operation of the ethylbenzene liquid-phase oxidation reaction, and improves the economic benefit of the device.

Owner:WANHUA CHEM GRP CO LTD

Process for the liquid phase oxidation of ethylbenzene into ethylbenzene hydroperoxide

InactiveUS20080188674A1Reduce oxidationOrganic compound preparationPeroxy compound preparationEthylbenzene hydroperoxideOrganic chemistry

The invention relates to a process for the liquid phase oxidation of ethylbenzene into ethylbenzene hydroperoxide, wherein the ethylbenzene hydroperoxide concentration is kept below 20 wt. % on the basis of the total weight of the reaction mixture, and wherein styrene and / or a styrene derivative is fed to the ethylbenzene. The concentration of said styrene and / or a styrene derivative may be from 0.01 to 5.0 wt. %.

Owner:SHELL OIL CO

Method for preparing ethylbenzene hydroperoxide by liquid-phase peroxidation of ethylbenzene and preparation method of propylene oxide

ActiveCN109942470BActive influenceDoes not affect the efficiency of the epoxidation reactionOrganic compound preparationBulk chemical productionEthylbenzene hydroperoxideFluid phase

The present invention relates to a method for preparing ethylbenzene hydroperoxide by liquid-phase peroxidation of ethylbenzene and a method for preparing propylene oxide. The method promotes the reaction between ethylbenzene and gas containing oxygen molecules by adding a small amount of organic basic substances. peroxidation reaction. The method can effectively improve the selectivity of the target product, and the added organic basic substance will not affect the activity of the subsequent epoxidation catalyst.

Owner:WANHUA CHEM GRP CO LTD

A device and method for oxidation of organic matter

ActiveCN109967022BLiquid-gas reaction as foam/aerosol/bubblesOrganic compound preparationEthylbenzene hydroperoxideFluid phase

The invention discloses a device and a method for organic oxidation, in particular a method for preparing ethylbenzene hydroperoxide by reacting ethylbenzene with an oxygen-containing gas. The device comprises a vertical bubbling reactor and a The horizontal bubbling reactor of the reaction product outlet of the vertical bubbling reactor, the horizontal bubbling reactor is provided with multi-stage reaction compartments arranged along its axial direction, and the adjacent reaction compartments are provided with liquid channel. Through the clever combination of the reactors, the method enables the oxidation reaction of organic matter to be carried out under more favorable conditions, thereby improving the production capacity of the equipment.

Owner:WANHUA CHEM GRP CO LTD

Application of titanium silicalite molecular sieve catalyst

InactiveCN106316991AGood choiceImprove stabilityOrganic chemistryMolecular sieve catalystsSolventChemistry

The invention relates to application of a titanium silicalite molecular sieve catalyst. The catalyst is used in the process of producing corresponding epoxides through olefin epoxidation by taking H2O2, ethylbenzene hydroperoxide, isopropylbenzene hydroperoxide, tert-butyl hydroperoxide and the like as oxidizing agents. The catalyst is composed of a silicon source, a titanium source, a template agent, a mineralizer and a solvent, wherein the silicon source is Si(OR1)4, (R2O)3Si-(CH2)n1-Si(OR3)3 and (R4)n2-Si(OR5)4-n2; the titanium source is Ti(OR6)4; the template agent is [(CH3)3CH3(CH2)n3N<+>]X<->; the mineralizer is [(CH3Cn4H2n4)4NH4]<+>OH<->; the solvent is water. Moreover, because the molecular sieve structure contains organic functional groups and composite pores with hydrophobic property and carbon deposition resistance, the catalyst is excellent in hydrophobic property and mass transfer performance and high in activity, selectivity and stability.

Owner:QINGDAO WINCHANCE TECH

Method for preparing molecular sieve based catalyst

InactiveCN106311324AGood choiceImprove stabilityOrganic chemistryMolecular sieve catalystsCalcinationChemistry

The invention relates to a method for preparing a molecular sieve based catalyst. The method comprises the following steps: mixing and hydrolyzing a silicon source, a template agent, a mineralizer, water and ethanol at normal temperature; slowly adding a mixture of a titanium source and the residual silicon source into the hydrolyzed silicon hydroxide solution under rapid stirring, and forming gel; transferring the gel into a crystallization kettle for crystallization; washing, filtering and roasting a crystallized molecular sieve so as to remove the template agent, wherein the calcination temperature is 500-600 DEG C, and the calcination time is 4-6 hours to obtain the composite porous molecular sieve based catalyst. The catalyst is simple in preparation process and high in production efficiency; and moreover, because the molecular sieve structure contains organic functional groups and composite pores with hydrophobic property and carbon deposition resistance, the catalyst is excellent in hydrophobic property and mass transfer performance and high in activity, selectivity and stability, and can be used in the process of producing corresponding epoxides through olefin epoxidation by taking H2O2, ethylbenzene hydroperoxide, isopropylbenzene hydroperoxide, tert-butyl hydroperoxide and the like as oxidizing agents.

Owner:QINGDAO WINCHANCE TECH

Reaction device for preparing ethylbenzene hydroperoxide

ActiveCN113680302ASlow down the flowIncrease oxygenOrganic compound preparationTransportation and packagingEthylbenzene hydroperoxideStructural engineering

The invention relates to a reaction device for preparing ethylbenzene hydroperoxide. The reaction device comprises a plurality of reactors which are sequentially connected in series. Each reactor comprises a reactor body, and an exhaust pipe and an air inlet assembly which are communicated with the reactor body. Openings are formed in the two ends of each reactor body, and the openings of the plurality of reactors are sequentially communicated. A plurality of groups of radial baffles are arranged in each reactor body. In each group of radial baffles, there is at least one radial baffle with one end fixed to the side, close to the ground, of the reactor body and the other side overhung in the direction away from the ground, there is at least one radial baffle with one side fixed to the side, away from the ground, of the reactor body and the other side overhung in the direction close to the ground, and the projection parts of the two radial baffles in the vertical direction coincide. The number of the radial baffles in the reactor bodies is sequentially reduced in the material flowing direction. The radial baffles are arranged to achieve the purpose of improving the yield of ethylbenzene hydroperoxide.

Owner:浙江智英石化技术有限公司

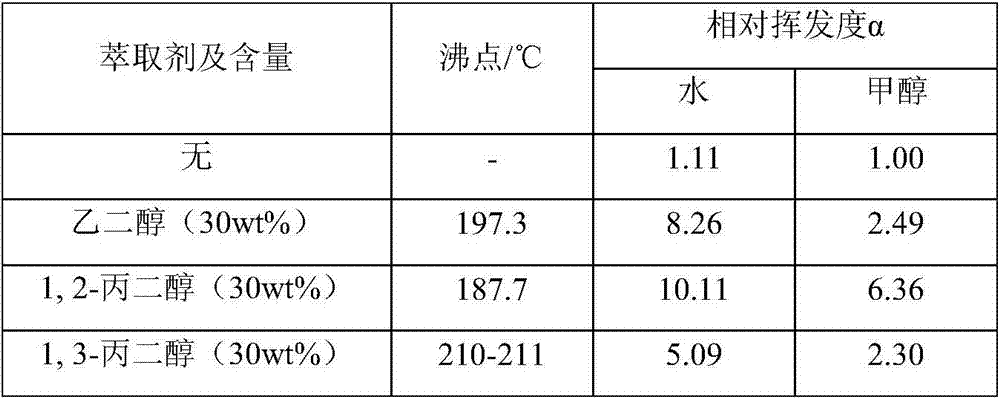

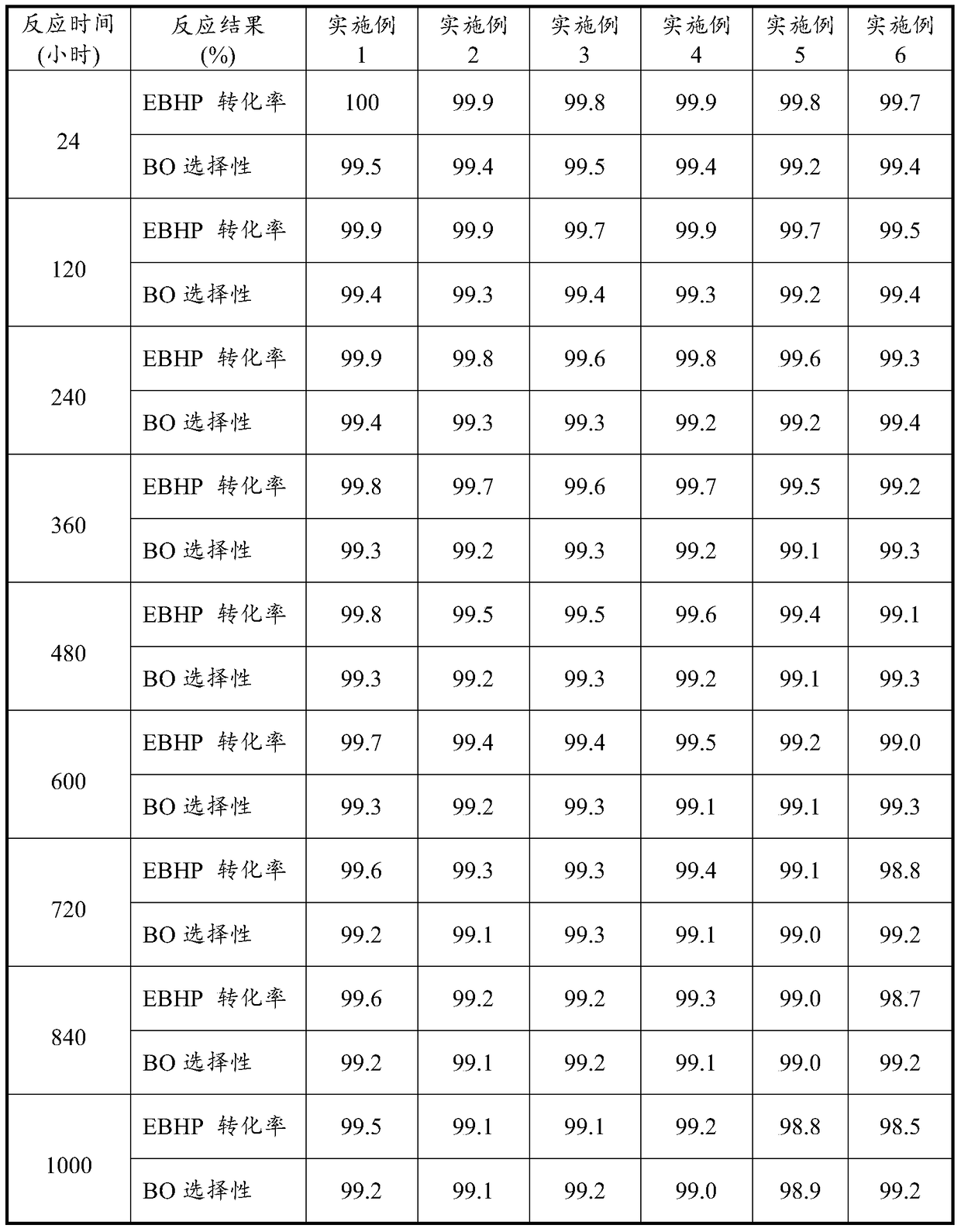

Purification method of propylene oxide

The present invention provides a kind of purification method of propylene oxide (PO), and this method is the purification method of EBHP (ethylbenzene hydrogen peroxide) method propylene oxide crude product, at first adopts C2~C6 alkyl glycol to make in deweighting tower The extractant removes impurities such as water, propionaldehyde, acetone, methanol, etc., and the kettle liquid enters the extractant recovery tower to recover the extractant and circulates to the upper part of the weight removal tower to feed, and the overhead distillate of the weight removal tower removes C3~ C4 light hydrocarbons, most of acetaldehyde and other impurities, the liquid in the delighting tower enters the extraction tower and uses C7-C20 hydrocarbons as the extraction agent to remove residual acetaldehyde, methanol, water and other impurities, the liquid in the extraction tower enters the product tower, and the product The tower uses C7-C20 hydrocarbons as the extraction agent to remove C5-C6 light hydrocarbons, and the propylene oxide product is obtained at the top of the tower, and the product tower liquid enters the solvent stripping tower to recover the extraction agent C7-C20 hydrocarbons, which can be used for propylene oxide ( Industrial application of PO) purification.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for producing butylene oxide

The invention relates to an epoxybutane production method to mainly solve the problems of large amount of wastewater and waste residues, severe pollution and strong apparatus corrosion existing in the prior art. The method comprises the following steps: 1, carrying out a peroxidation reaction on ethylbenzene and air to obtain an ethylbenzene hydroperoxide oxidation solution; 2, carrying out an epoxidation reaction on the ethylbenzene hydroperoxide oxidation solution and butylene under the action of a catalyst under liquid phase conditions to generate epoxybutane, alpha-methylbenzyl alcohol and acetophenone; 3, dehydrating alpha-methylbenzyl alcohol to generate styrene; and 4, carrying out a hydrogenation reaction on acetophenone and hydrogen to generate alpha-methylbenzylalcohol, returning the generated alpha-methylbenzylalcohol to step 3, and hydrogenating the returned alpha-methylbenzylalcohol and the alpha-methylbenzylalcohol generated in step 2 to generate styrene. The method adopting the above technical scheme well solves the problems, can be used in industrial production for preparation of epoxybutane and combined production of styrene.

Owner:CHINA PETROLEUM & CHEM CORP +1

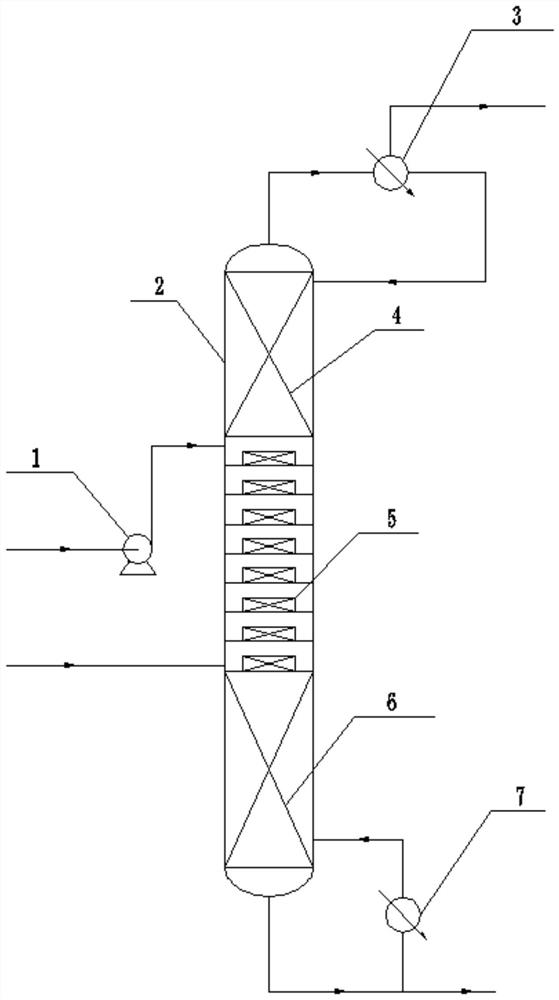

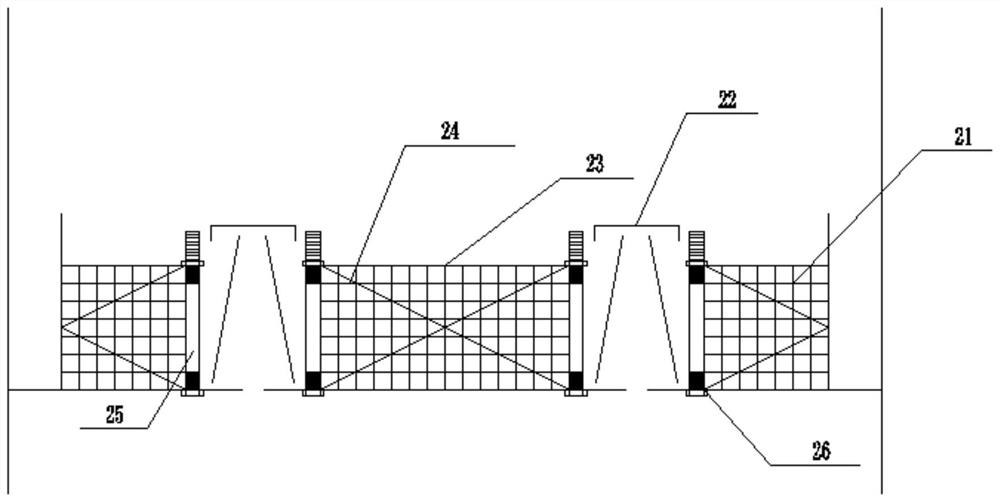

Method for preparing ethylbenzene hydroperoxide through ethylbenzene reactive distillation and reactive distillation tower thereof

ActiveCN112174868AImprove efficiencyMeet the reaction contact timeOrganic compound preparationChemical industryEthylbenzene hydroperoxidePtru catalyst

The invention discloses a method for preparing ethylbenzene hydroperoxide through ethylbenzene reactive distillation and a reactive distillation tower thereof. A catalyst bag is fixed between gas raising covers of a tower plate, and the catalyst bag further comprises a strip-shaped catalyst. The method is high in efficiency, raw materials pass through the catalyst and the tower plate separation and purification element repeatedly, and the conversion rate and selectivity are improved. Meanwhile, the manufacturing is easy, the mounting and dismounting are convenient, and follow-up treatment is simplified.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com