Method for improving stability of ethylbenzene hydroperoxide

A technology of ethylbenzene hydroperoxide and stability, applied in the direction of preparation of peroxygen compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as unproposed solutions, reduce scaling problems, and improve selection The effect of sex and productivity and difficulty reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A method for improving the stability of ethylbenzene hydroperoxide, comprising the steps:

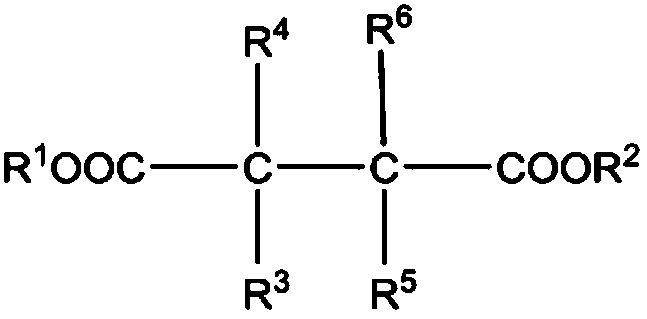

[0056] In three identical bubble tower oxidation reactor devices, ethylbenzene and succinic acid derivatives are mixed by a mixer and then enter the first oxidation reactor, nitrogen and oxygen mixed gas containing 23v% oxygen flow from the reactor The bottom enters and reacts, wherein the general formula of the succinic acid derivative used is as follows:

[0057]

[0058] Among them, R 1 is ethyl, R 2 is ethyl, R 3 is n-propyl, R 4 is n-propyl, R5 is n-butyl, R 6 For n-butyl. In the first oxidation reactor, the feed rate of ethylbenzene is 1kg / h, the content of succinic acid derivatives in the ethylbenzene feed is controlled to be 70mg / kg, the reaction temperature is 156°C, the reaction pressure is 0.20MPa, and the residence time of the reaction liquid phase is After 45min, enter the second reactor, the reaction temperature is 154°C, the reaction pressure is 0.20MPa, t...

Embodiment 2

[0060] A method for improving the stability of ethylbenzene hydroperoxide, comprising the steps:

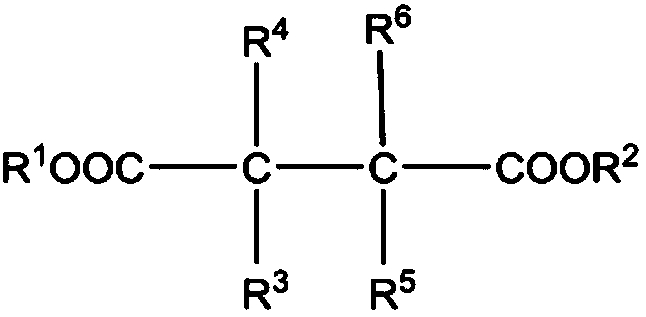

[0061] Experiments were carried out in four identical bubble tower oxidation reactor devices. After ethylbenzene and succinic acid derivatives were mixed through a mixer, they entered the first oxidation reactor, and nitrogen and oxygen mixed gas containing 23v% oxygen were fed from The bottom of the reactor enters and reacts, wherein the general formula of the succinic acid derivative used is as follows:

[0062]

[0063] Among them, R 1 is methyl, R 2 is methyl, R 3 for hydrogen, R 4 for hydrogen, R 5 is n-butyl, R 6 For n-butyl. In the first oxidation reactor, the amount of ethylbenzene feed is 1kg / h, the content of succinic acid derivatives in the ethylbenzene feed is controlled to be 85mg / kg, the reaction temperature is 160°C, the reaction pressure is 0.20MPa, and the reaction liquid phase stays The time is 40min, then enter the second reactor, the reaction tempera...

Embodiment 3

[0065] A method for improving the stability of ethylbenzene hydroperoxide, comprising the steps:

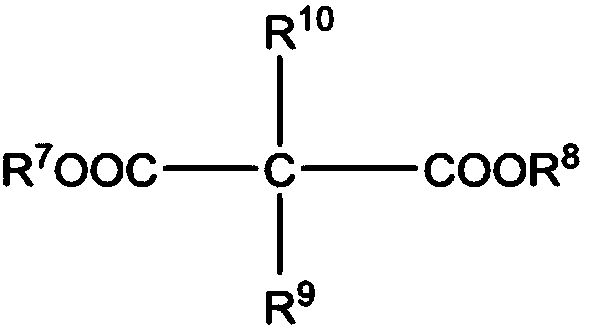

[0066] Tests were carried out in three identical bubble tower oxidation reactor devices. After ethylbenzene and malonic acid derivatives were mixed through a mixer, they entered the first oxidation reactor, and nitrogen and oxygen mixed gas containing 23v% oxygen were fed from The bottom of the reactor enters and reacts, wherein the general formula of the malonic acid derivative used is as follows:

[0067]

[0068] Among them, R 7 is n-butyl, R 8 is n-butyl, R 9 is methyl, R 10 For methyl. In the first oxidation reactor, the feed amount of ethylbenzene is 1kg / h, the malonic acid derivative content in the ethylbenzene feed is controlled to be 65mg / kg, the reaction temperature is 162°C, the reaction pressure is 0.20MPa, and the reaction liquid phase stays Time is 45min, then enters the second reactor, the reaction temperature is 161°C, the reaction pressure is 0.20MPa, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com