Production method for epichlorohydrin

A technology for epichlorohydrin and a production method, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., can solve pollution, strong equipment corrosion, large amount of waste water and waste, etc. problem, to achieve the effect of good technical effect, high catalyst activity and high product selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

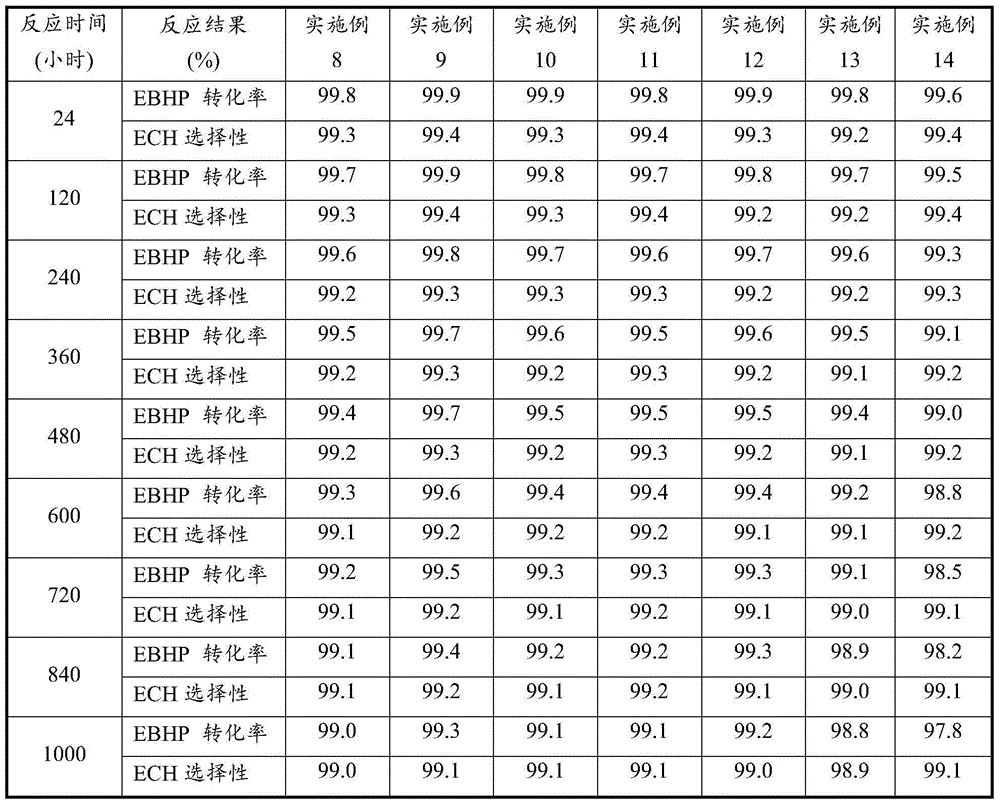

Examples

Embodiment 1

[0035] At room temperature and under stirring, 150g of hexadecylamine was added to the solution containing 800ml of H 2 O and 600ml of ethanol mixed solution, stirred until the solution was one phase. Add 650 g of ethyl orthosilicate dissolved in 300 ml of ethanol to the above mixed solution, stir for 30 min and then crystallize for 24 h. The resulting solid was then filtered and washed with water. The washed material was dried at 110°C for 12 hours, and then calcined at 550°C for 4 hours to obtain a powder carrier with HMS structure characteristics. Using silica sol as a binder, a HMS molding carrier with a HMS weight percentage of 90% was prepared by using traditional extrusion molding technology.

[0036] Configuration contains 40gTiCl 4 500ml of cumene solution, the above-mentioned prepared catalyst shaped carrier is added to TiCl 4 In the solution, under slow stirring and reflux, the temperature was raised to 150°C, and the reaction was carried out at this temperature...

Embodiment 2

[0040] According to the method of [Example 1], an HMS shaped carrier with a HMS weight percentage of 90% was prepared. Take 100 grams of the shaped carrier prepared above and fill it into a quartz tube reactor, and heat it at 120° C. for 2 hours under dry air conditions. Raise the bed temperature to 200°C, under normal pressure, continuously feed TiCl 4 Dry air at 5.0% by volume for 6 hours. At this temperature and pressure, switch to air purge until the reactor outlet is TiCl-free 4 Check out. Then pass air with a water vapor volume content of 1.0% for 5 hours, and then switch to air to purge the residual water vapor in the system. Dry air with a hexamethyldisilazane volume content of 10.0% was continued for 6 hours. At this temperature and pressure, switch to nitrogen purge until no hexamethyldisilazane is detected at the outlet of the reactor, that is, a titanium-containing porous silica catalyst Ti- HMS.

[0041] The elemental analysis results showed that the weight ...

Embodiment 3

[0043] Add 150 g of fumed silica into 240 g of 25 wt % tetramethylammonium hydroxide aqueous solution, and continue stirring for 30 min to form a solution. Then, the above solution was added to 600 ml of aqueous solution containing 230 g of cetyltrimethylammonium bromide under stirring to form a transparent solution. The above mixed solution was transferred into a stainless steel autoclave lined with polytetrafluoroethylene at 100°C for static crystallization for 3 days. The crystallized product is washed and filtered, dried at 100°C for 24 hours, and calcined at 550°C for 6 hours to obtain a powder carrier with the structural characteristics of MCM-41. The MCM-41 molding carrier with the MCM-41 weight percentage of 90% is prepared by using silica sol as a binder and adopting traditional extrusion molding technology.

[0044] According to the method of [Example 2], the assembly of the active species titanium and the surface hydrocarbyl graft silanization treatment are carried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com