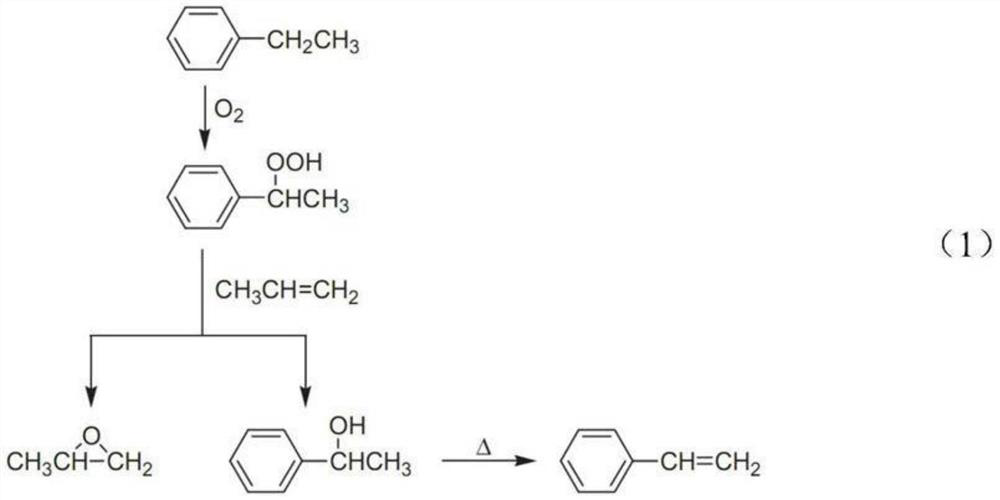

Method for preparing ethylbenzene hydroperoxide through ethylbenzene reactive distillation and reactive distillation tower thereof

A technology of ethylbenzene hydroperoxide and rectification tower, which is applied in the preparation of peroxy compounds, chemical instruments and methods, separation methods, etc. The temperature control of the reactor is complex and other problems, so as to meet the reaction contact time, simplify the follow-up treatment, and improve the conversion rate and selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

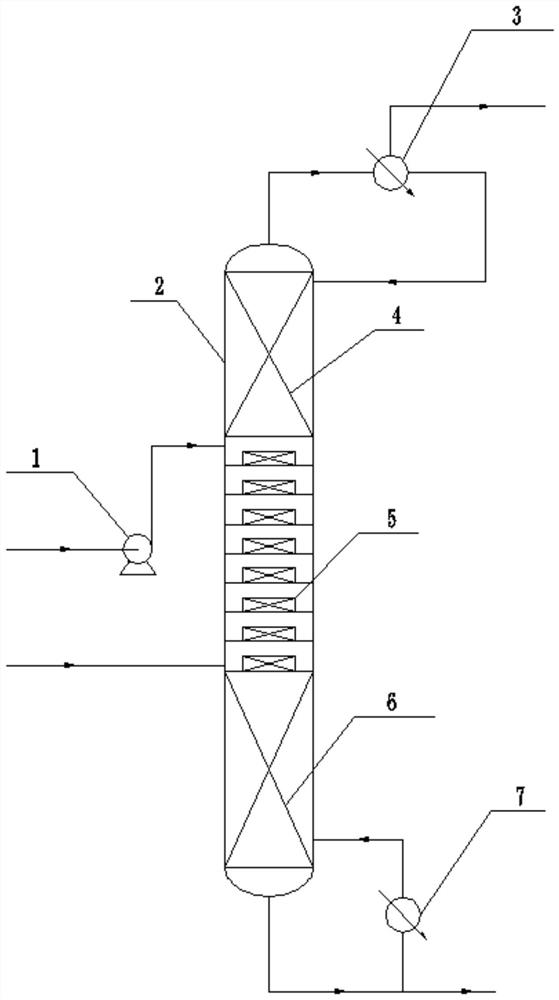

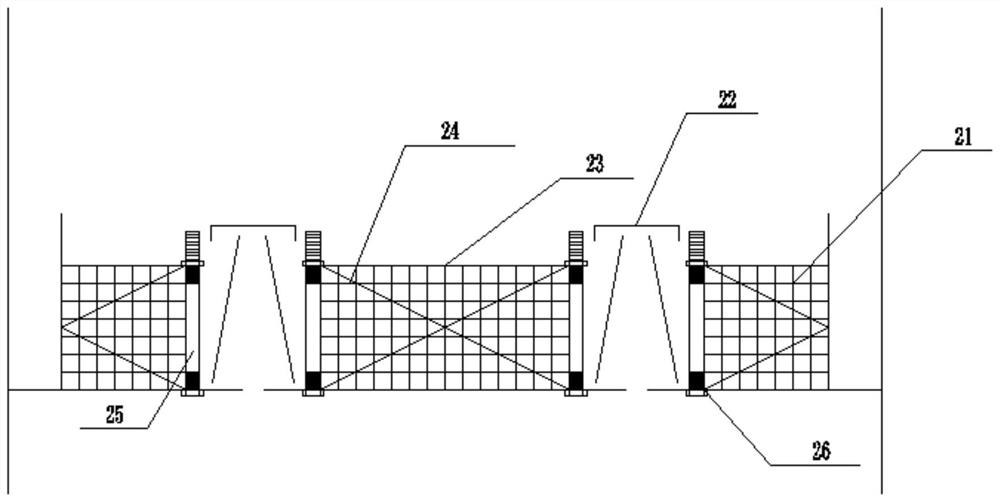

[0051] The method and device thereof for preparing ethylbenzene hydroperoxide by catalytic reaction rectification of the present embodiment are as described above, and the specific operating parameters are:

[0052] Catalytic reaction rectification tower, tower diameter 1.8m, 3m packing in rectification section, 3m packing in stripping section, 40 layers of catalytic reaction rectification trays in catalytic reaction section, the number of hoods on the trays in catalytic reaction section is 20, The total area of each catalyst package is 1.05m 2 , with a volume of 0.12m 3 , The quality of each layer of catalyst is 250kg.

[0053] The operating conditions are: tower top pressure 0.2MPaG, tower top temperature 42°C, tower bottom temperature 83°C, reflux ratio 6, space velocity 4h -1 .

[0054] After normal operation, the conversion rate of ethylbenzene is 10.52%, and the selectivity of EBHP is 91.5%.

Embodiment 2

[0060] The method and device thereof for preparing ethylbenzene hydroperoxide by catalytic reaction rectification of the present embodiment are as described above, and the specific operating parameters are:

[0061] Catalytic reaction rectification tower, tower diameter 1.8m, 3m packing in rectification section, 3m packing in stripping section, 40 layers of catalytic reaction rectification trays in catalytic reaction section, the number of hoods on the trays in catalytic reaction section is 24, The total area of each catalyst package is 1.20m 2 , with a volume of 0.15m 3 , The quality of each layer of catalyst is 300kg.

[0062] The operating conditions are: tower top pressure 0.4MPaG, tower top temperature 61°C, tower bottom temperature 98°C, reflux ratio 4, space velocity 5h -1 .

[0063] After normal operation, the conversion rate of ethylbenzene is 10.63%, and the selectivity of EBHP is 92.8%.

Embodiment 3

[0065] The method and device thereof for preparing ethylbenzene hydroperoxide by catalytic reaction rectification of the present embodiment are as described above, and the specific operating parameters are:

[0066] Catalytic reaction rectification tower, tower diameter 1.8m, rectification section 3m packing, stripping section 3m packing, catalytic reaction section 40 catalytic reaction rectification trays, the number of hoods on the catalytic reaction section tray is 22, The total area of each catalyst package is 1.12m 2 , with a volume of 0.14m 3 , The quality of each layer of catalyst is 275kg.

[0067] The operating conditions are: tower top pressure 0.8MPaG, tower top temperature 80°C, tower bottom temperature 123°C, reflux ratio 8, space velocity 5h -1 .

[0068] After normal operation, the conversion rate of ethylbenzene is 10.56%, and the selectivity of EBHP is 94.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com