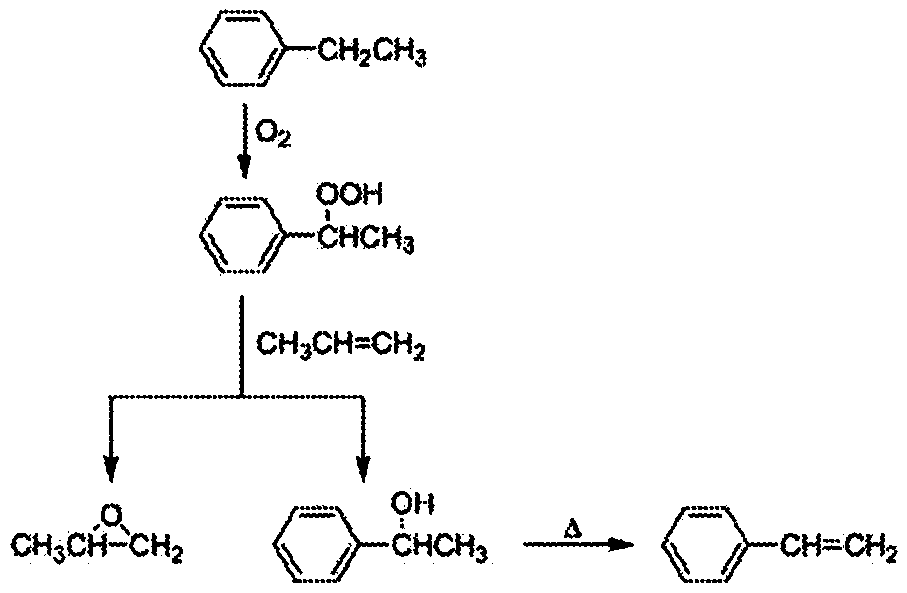

Multistage horizontal stirred air-lift reactor for preparing EBHP and application thereof

A reactor and stirring gas technology, which is applied in the field of reactors for preparing organic peroxides, achieves the effects of safe and reliable operation, improved flexibility, and improved gas distribution uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

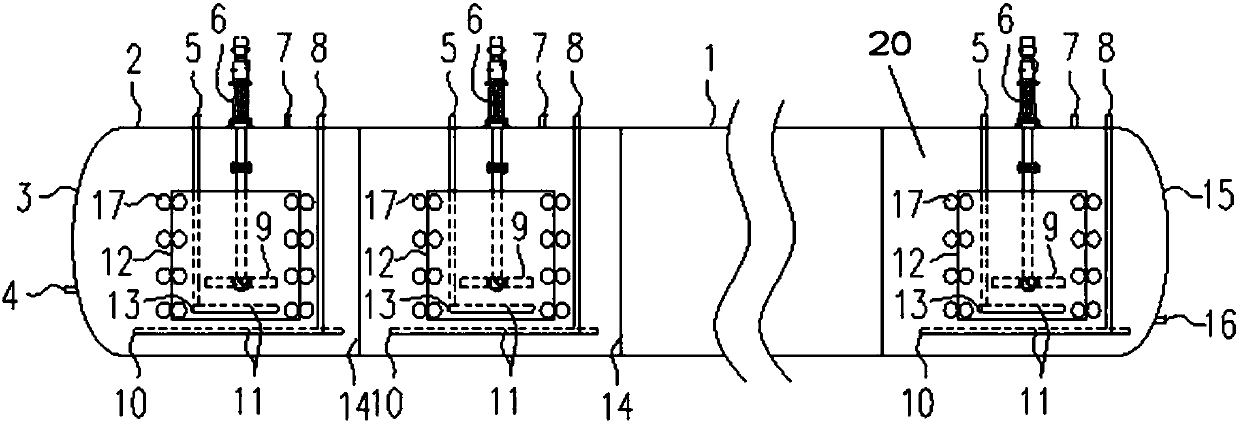

[0041] use as figure 1 The reactor shown. The reactor 1 has a diameter of about 1.5 meters and a length of about 6 meters. The reactor was divided into four reaction compartments 20 by using three partitions 14, and a liquid flow channel with a diameter of 100 mm was left at the bottom of the partitions 14. The middle part of each compartment is provided with a guide tube 12 perpendicular to the direction of liquid flow, the diameter of the guide tube 12 is 40% of the diameter of the reactor 1, the height of the guide tube 12 is 50% of the diameter of the reactor 1, and the bottom of the guide tube 12 The distance to the reactor wall is 10% of the reactor 1 diameter. A stirring device 6 is arranged in the center of the guide tube 12, and the stirring device 6 includes two layers of stirring paddles 9, the lower layer is a six-concave-blade disc turbine, and the upper layer is a six-pitched-blade stirring paddle. A first gas distributor 10 and a second gas distributor 13 are...

Embodiment 2

[0045] The difference from Example 1 is that the diameter of the guide tube 12 is 60% of the diameter of the reactor 1, and the height of the guide tube 12 is 60% of the diameter of the reactor 1; the central stirring device of the guide tube 12 is changed to a single-layer six inclined blade mixer.

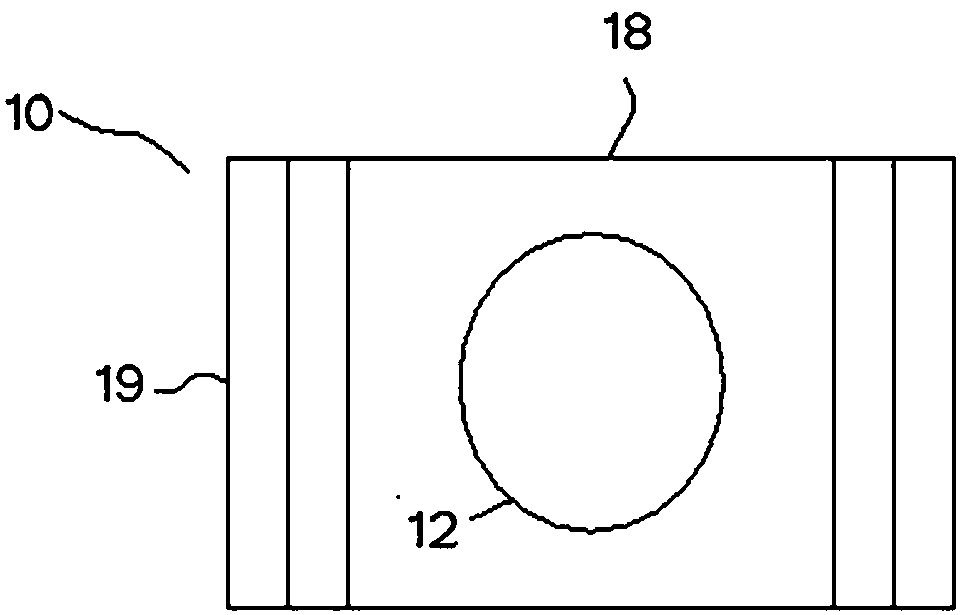

[0046] A first gas distributor 10 and a second gas distributor 13 are respectively provided outside and inside the guide tube 12, wherein the second gas distributor 13 adopts a ring-shaped gas distribution device, which is substantially flat with the lower end of the guide tube 12. Arranged uniformly, on which about 28 air distribution holes are arranged according to the gas flow of each compartment; similar figure 2 The gas distribution device shown includes two gas distribution main pipes 18, but the number of gas distribution branch pipes 19 is reduced from six to four, and about 22 gas distribution holes are arranged on it according to the gas flow rate of each compartment. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com