Method for preparing ethylbenzene hydroperoxide through oxidation of ethylbenzene

A technology of ethylbenzene hydroperoxide and ethylbenzene, which is applied to the preparation of peroxygen compounds, chemical instruments and methods, and the preparation of organic compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

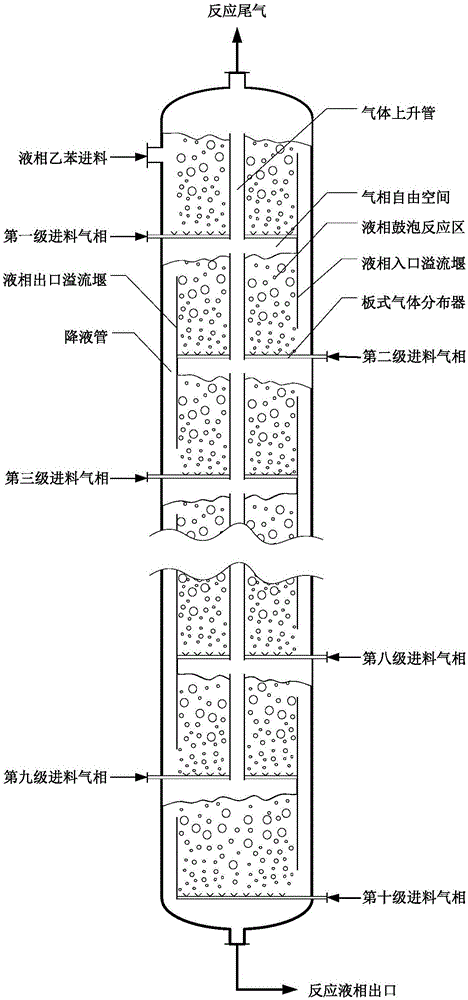

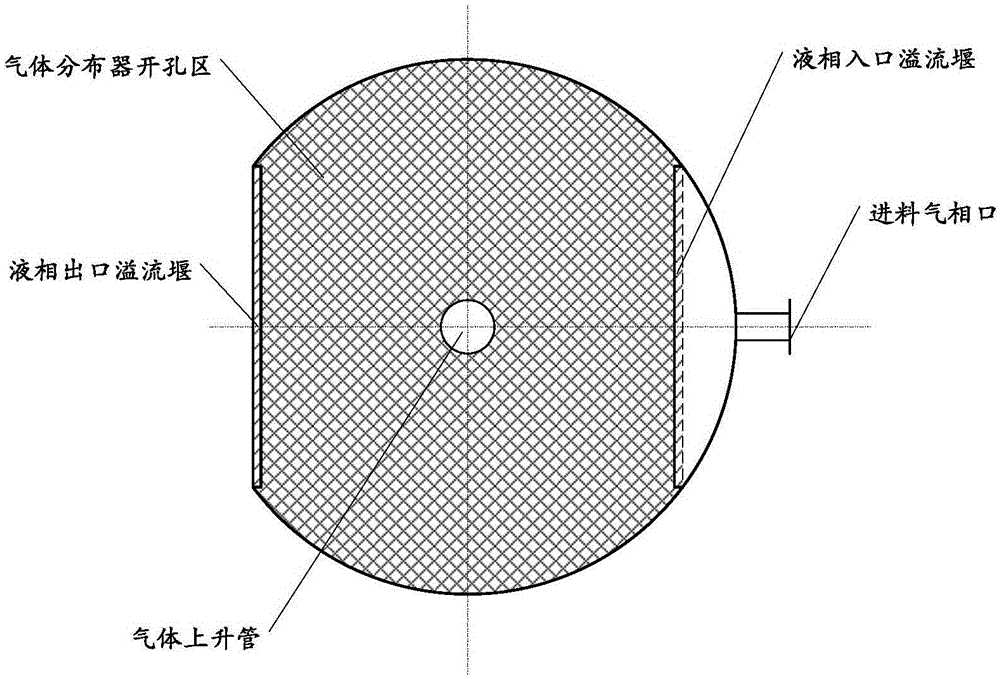

[0044] A vertical multi-stage bubble column reactor was used to carry out a pilot-scale model experiment of ethylbenzene air oxidation to ethylbenzene hydroperoxide (EBHP), and the feeding rate of ethylbenzene raw material was 100kg / hr. The inner diameter of the reactor tower is 0.2m, and the total height is 12m. The bubbling reaction zone of the reactor is ten stages, and the tenth stage has no tray member, only contains the feed gas phase pipe and gas distributor, and the tray member is a non-porous tower. Plate, using a plate-type gas distributor, the integrated design of the gas distributor and the tray, the opening diameter of the gas distributor is 0.2mm, the opening rate is 3%, and it is equipped with a gas riser, a downcomer, and a liquid phase outlet overflow weir and the liquid phase inlet overflow weir, the height of the liquid phase outlet overflow weir of each reactor is 0.6m, and the basic structure diagram of the reactor is shown in figure 1 , 2 As shown, the u...

Embodiment 2

[0050]In a manner similar to that of Example 1, a pilot-scale model experiment for the production of EBHP by liquid-phase oxidation of ethylbenzene was carried out, and the feeding rate of ethylbenzene raw material was 100 kg / hr. Adopt the same multi-stage bubbling reactor as in Example 1 (the inner diameter of the tower is 0.2m, the total height is 12m), and the bubbling area of the reactor is ten stages. The difference is that the residence time of the liquid phase at each level is optimized through the reaction series and the reaction temperature at each level. The optimized residence time of each level is 12min, 11min, 10min, 9min, 8min, 8min, 9min, 10min, 11min, and 12min. The concentration of ethylbenzene hydroperoxide in the first-stage reactor is 1.15wt%, and the concentration difference of ethylbenzene hydroperoxide in the adjacent two-stage reactor is 0.9~1.0wt%. The concentration of oxides was 9.25% by weight. The liquid phase feed temperature is 150°C, the top g...

Embodiment 3

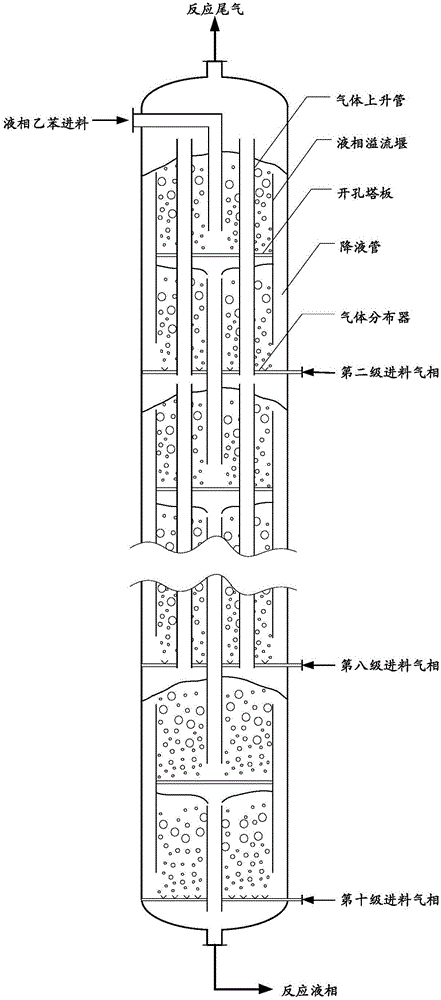

[0064] The industrial production of ethylbenzene hydroperoxide (EBHP) by air oxidation of ethylbenzene is carried out by using a vertical multi-stage bubble column reactor. The diameter of the bubble column reactor is 5.0m, and the total height is 35m. The bubbling reaction zone of the reactor has ten stages, and each stage is equipped with three gas risers arranged in parallel. The gas risers of two adjacent stages are arranged in a staggered manner, and the height of the overflow weir at the outlet of each stage reactor is 2.5m. The components are open-hole trays, and each two-stage bubbling reaction area is equipped with a set of gas distributor and gas phase feed port, and a deflector 1 is installed in the liquid phase channel, and the downcomers of the adjacent two stages are respectively placed A single circular tube in the center of the tray and multiple arcuate tubes arranged in parallel on the edge of the tray; the guide plate 1 is placed according to the characteristi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com