Reaction device for preparing ethylbenzene hydroperoxide

A technology of ethylbenzene hydrogen peroxide and reaction device, which is applied in the direction of peroxy compound preparation, feeding device, chemical/physical/physicochemical fixed reactor, etc., can solve the problems of low yield of ethylbenzene hydrogen peroxide, etc. To achieve the effects of prolonging the mixing time, increasing the amount of oxygen, and increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

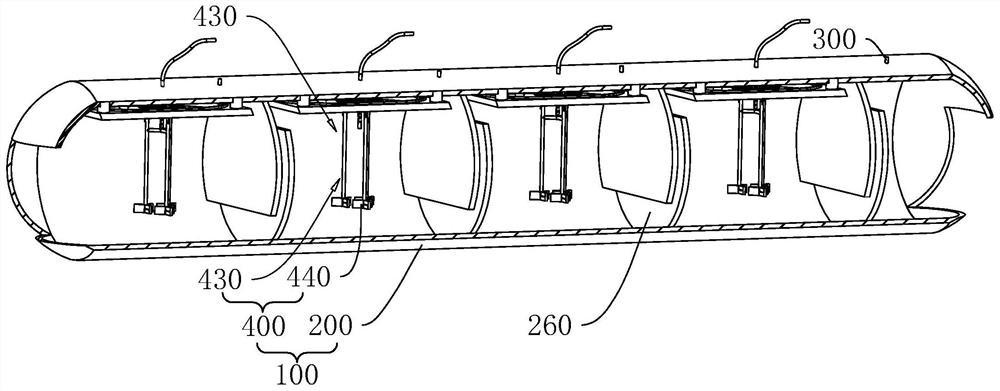

[0043] The difference between this embodiment and Embodiment 1 is: refer to image 3 and Figure 4 , the intake assembly 400 includes a gas filling pipe 430 and a plurality of gas filling plates 440 . The gas-filling pipe 430 includes a connecting sub-pipe 431 and a plurality of gas-filling sub-pipes 432. One end of the connecting sub-pipe 431 passes through the inner wall of the reactor body 200 to connect with the pumping device, and the connecting sub-pipe 431 is connected to the pumping device through a rotary joint. The joint is located in the reactor body 200 , and the other end of the connecting sub-pipe 431 communicates with a plurality of gas-filling sub-pipes 432 . The number of gas-filling sub-pipes 432 is consistent with the number of gas-filling plates 440 , and the gas-filling sub-pipes 432 correspond to the gas-filling plates 440 one-to-one. In this embodiment, there are three gas-filling sub-pipes 432, and the three gas-filling sub-pipes 432 are evenly arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com