Process for producing butylene oxide

A technology of butylene oxide and oxidation solution, which is applied in the direction of hydrocarbon production from oxygen-containing organic compounds, organic chemistry, etc., can solve the problems of pollution, strong corrosion of equipment, large amount of waste water and waste residue, etc., and achieve good technical and economical efficiency. The effect of technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Under the conditions of 160°C, 0.4MPa, and controlling the volume content of tail oxygen to less than 5%, ethylbenzene and air undergo peroxidation reaction to obtain hydrogen peroxide ethylbenzene oxidation solution with a weight concentration of 10%, which is obtained by vacuum concentration. Concentration of 30% ethylbenzene hydrogen peroxide (EBHP) oxidation solution.

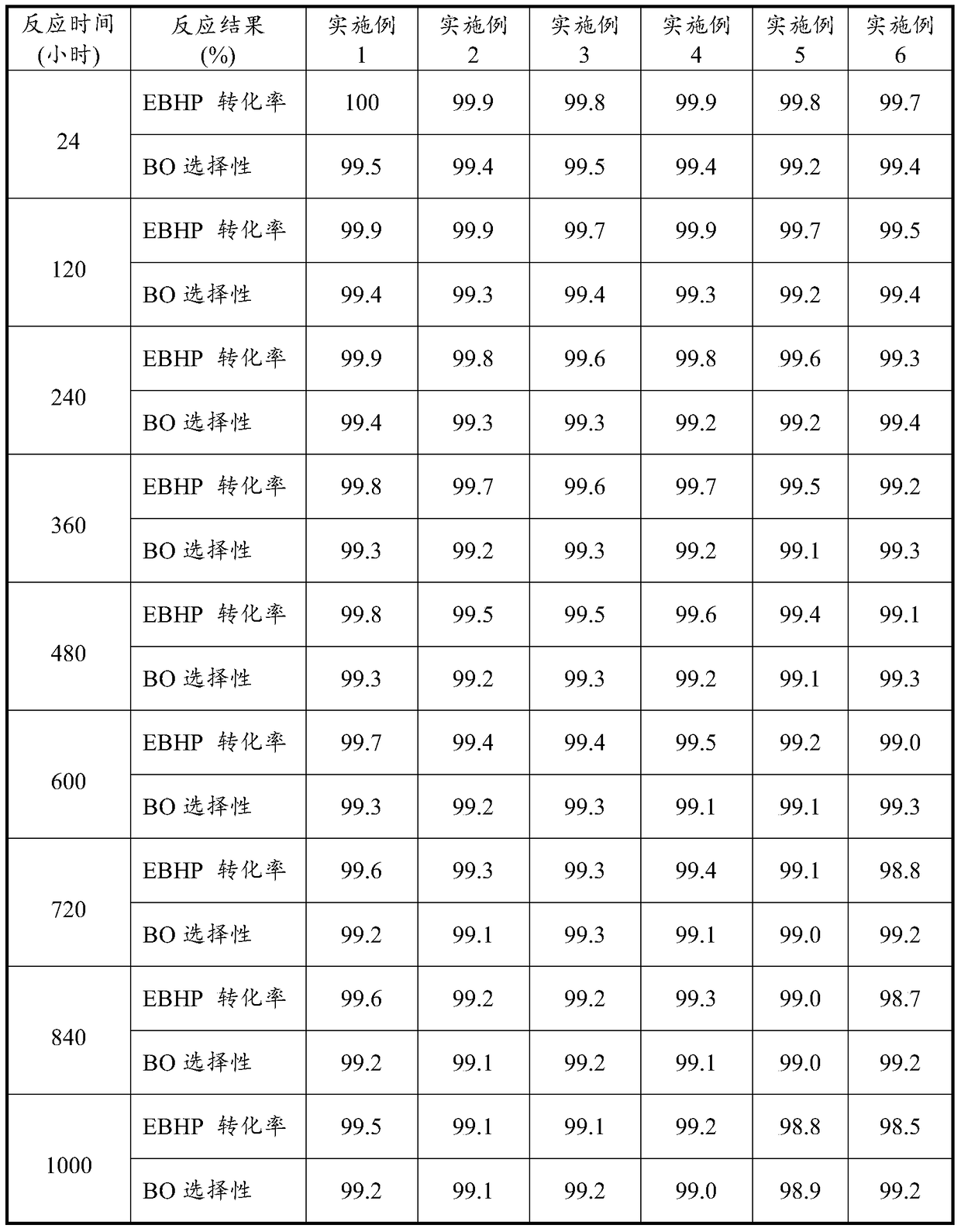

[0033] The above-mentioned weight concentration is 30% ethylbenzene hydrogen peroxide oxidation solution in the presence of Ti-HMS catalyst (the weight percentage of Ti is 1.6%), and 1-butene is carried out epoxidation reaction in fixed-bed reactor Generate 1,2-epoxybutane, α-methylbenzyl alcohol and a small amount of acetophenone. Wherein 1-butene / EBHP=4:1 (mol), the gravimetric space velocity of EBHP=3 hours -1 , the reaction temperature is 105°C, and the reaction pressure is 3.5MPa. The reaction results are shown in Table 1.

[0034] Pass the reaction mixture into a butene recovery tower to rec...

Embodiment 2

[0036] Under the conditions of 150°C, 0.3MPa, and controlling the volume content of tail oxygen to less than 5%, ethylbenzene and air undergo peroxidation reaction to obtain hydrogen peroxide ethylbenzene oxidation solution with a weight concentration of 10%, which is obtained by vacuum concentration. Concentration of 28% ethylbenzene hydroperoxide (EBHP) oxidation solution.

[0037] The above-mentioned weight concentration is that the hydrogen peroxide ethylbenzene oxidation liquid of 28% is in the presence of Ti-MCM-41 catalyst (the weight percent composition of Ti is 2.0%), and carries out epoxidation with 2-butene in a fixed-bed reactor The reaction produces 2,3-epoxybutane, α-methyl benzyl alcohol and a small amount of acetophenone. Wherein 2-butene / EBHP=7:1 (mol), the gravimetric space velocity of EBHP=4 hours -1 , the reaction temperature is 98°C, and the reaction pressure is 3.0MPa. The reaction results are shown in Table 1.

[0038] Pass the reaction mixture into a...

Embodiment 3

[0040] Under the conditions of 155°C, 0.35MPa, and controlling the volume content of tail oxygen to less than 5%, ethylbenzene and air undergo peroxidation reaction to obtain hydrogen peroxide ethylbenzene oxidation solution with a weight concentration of 10%, which is obtained by vacuum concentration. Concentration of 30% ethylbenzene hydrogen peroxide (EBHP) oxidation solution.

[0041] The above weight concentration is 30% ethylbenzene hydrogen peroxide oxidation solution in the presence of Ti-TUD-1 catalyst (the weight percentage of Ti is 1.5%), in a fixed bed reactor and isobutylene to carry out epoxidation reaction to generate 2-Methyl-1,2-propylene oxide, α-methylbenzyl alcohol and a small amount of acetophenone. Wherein isobutylene / EBHP=6:1 (mol), the gravimetric space velocity of EBHP=4 hours -1 , the reaction temperature is 100°C, and the reaction pressure is 3.5MPa. The reaction results are shown in Table 1.

[0042] Pass the reaction mixture into a butene recove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com