Synthesis method of 2-phenyl-2-propanol and acetophenone through catalytic oxidation of cumene

A technology for catalytic oxidation and cumene, applied in chemical instruments and methods, preparation of oxygenated compounds by oxidation of hydrocarbons, preparation of peroxygen compounds, etc., to achieve the effects of good selectivity, environmental friendliness, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

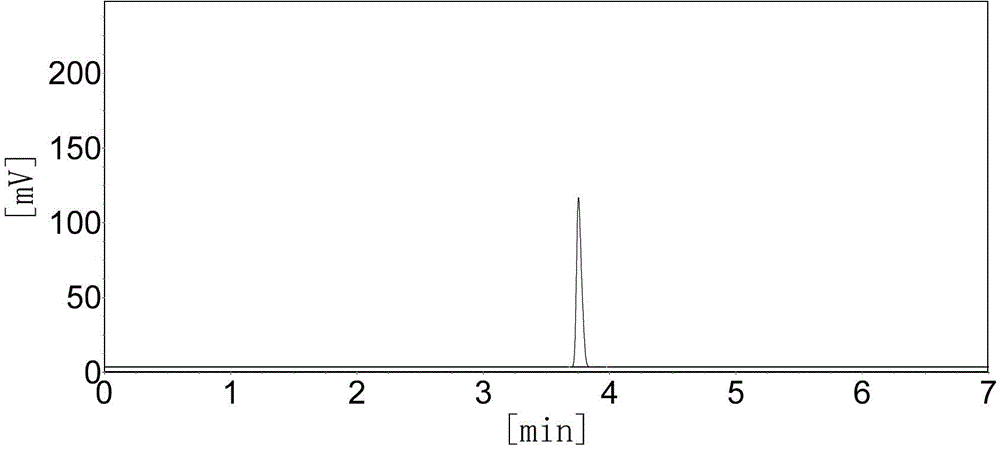

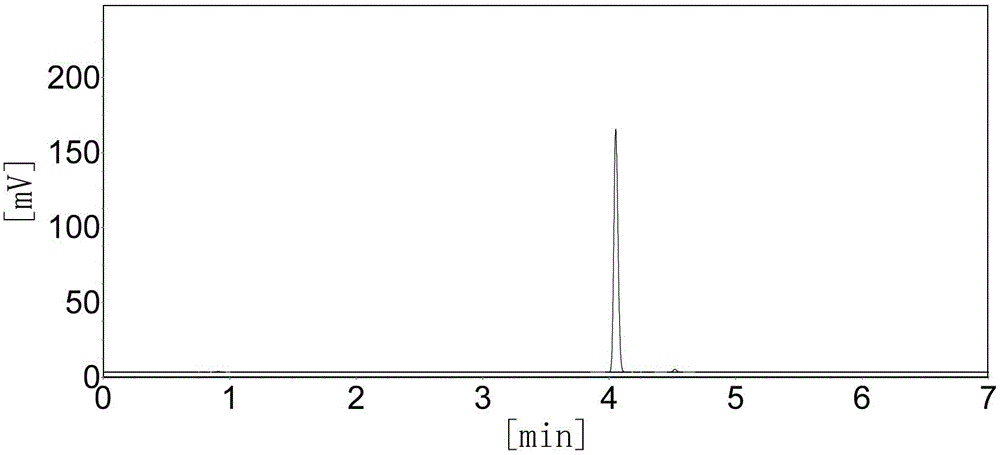

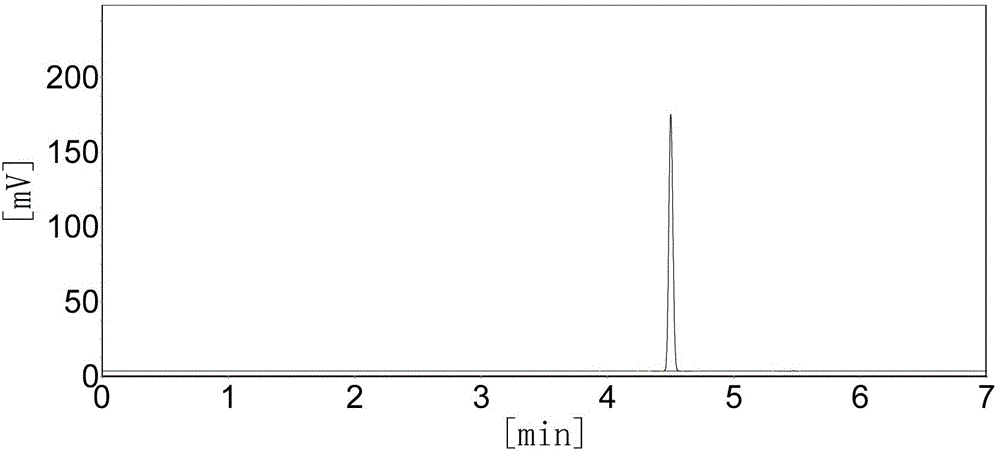

[0038] With 10.00mL cumene (density is 0.84g / mL) and 100mg nitrogen-doped carbon nanotubes with different nitrogen content (catalyst and cumene weight ratio are 0.012: 1, nitrogen content see Table 1, the nitrogen content in the table is mass content) into a three-necked flask, ultrasonicated for 2min (frequency 40kHz, 30°C) to form a mixed suspension. Then, under magnetic stirring, the mixture was placed in an oil bath and heated to 80° C., then oxygen was introduced at a rate of 10 mL / min, and the reaction was carried out under normal pressure for 8 h. After the reaction, the obtained mixed solution is filtered to obtain a solid catalyst and a liquid mixture containing 2-phenyl-2-propanol, acetophenone and CHP. Image 6 Be the gas chromatogram of embodiment 2, contrast Figure 1~5 The gas chromatogram of acetonitrile, toluene, cumene, acetophenone and 2-phenyl-2 propanol standard samples, it can be seen that the product after triphenylphosphine reduction is 2-phenyl-2-propan...

Embodiment 5~6

[0043] Add 10.00 mL of cumene (density 0.84 g / mL) and 100 mg of solid nitrogen-doped carbon material (the weight ratio of catalyst to cumene is 0.012:1, see Table 2 for the types of solid nitrogen-doped carbon material) into a three-necked flask , sonicate for 2min (frequency 40kHz, 30°C) to form a mixed suspension. Then, under magnetic stirring, the mixture was placed in an oil bath and heated to 80° C., then oxygen was introduced at a rate of 10 mL / min, and the mixture was reacted for 8 hours under normal pressure. After the reaction, the resulting mixed solution can be filtered to obtain a solid catalyst and a liquid mixture. The liquid mixture was analyzed to measure the conversion rate of cumene and the selectivity of the product, and the results are shown in Table 2. Analysis of the data in Tables 1 and 2 shows that nitrogen-doped carbon nanotubes have better catalytic activity and target product selectivity in the liquid-phase catalytic oxidation of cumene. Using nitr...

Embodiment 7~9

[0047] Add 10.00 mL of cumene (density of 0.84 g / mL) and 100 mg of nitrogen-doped carbon nanotubes (the nitrogen content is the same as in Example 3, and the weight ratio of catalyst to cumene is 0.012:1) into a three-necked flask, and ultrasonicate for 2 min (Frequency 40kHz, 30°C, can also be ultrasonicated for 5min) to form a mixed suspension. Then, under magnetic stirring, the mixed suspension was placed in an oil bath and heated to a predetermined reaction temperature (as shown in Table 3), and oxygen was introduced at a rate of 10 mL / min under normal pressure for 8 hours of reaction. After the reaction, the resulting mixed solution can be filtered to obtain a solid catalyst and a liquid mixture. The liquid mixture was analyzed to measure the conversion rate of cumene and the selectivity results of acetophenone and 2-phenyl-2-propanol in Table 3. Comparing Examples 7, 8, 3 and 9, it can be seen that the temperature increase is conducive to the oxidation of cumene, and al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com