Purification method of propylene oxide

A technology of propylene oxide and purification methods, applied in the direction of organic chemistry, etc., can solve the problems of accumulation of impurities, disadvantages, and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

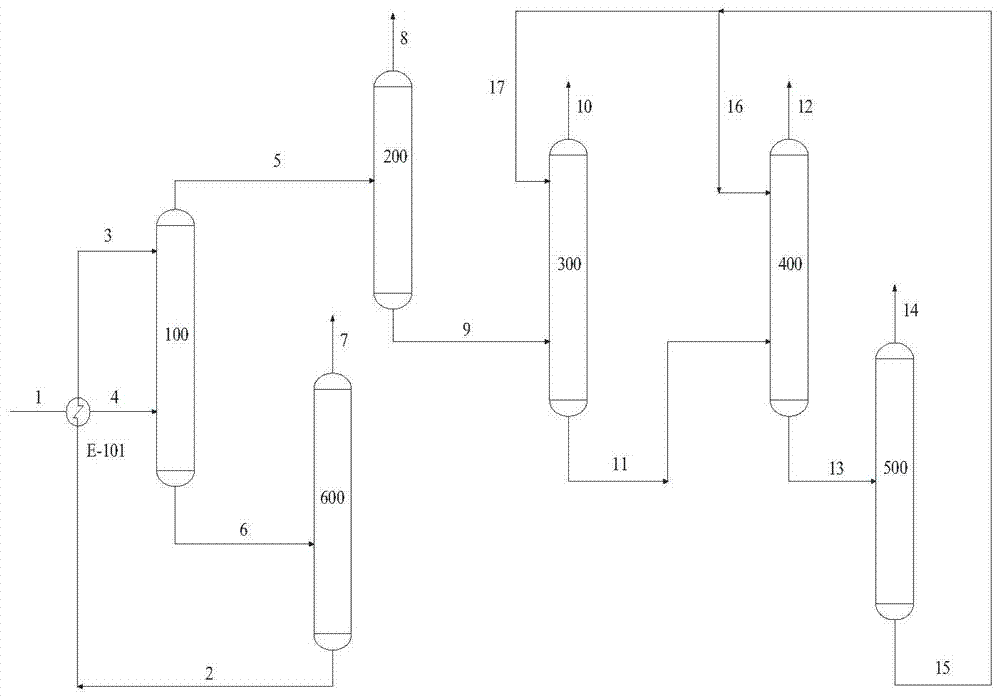

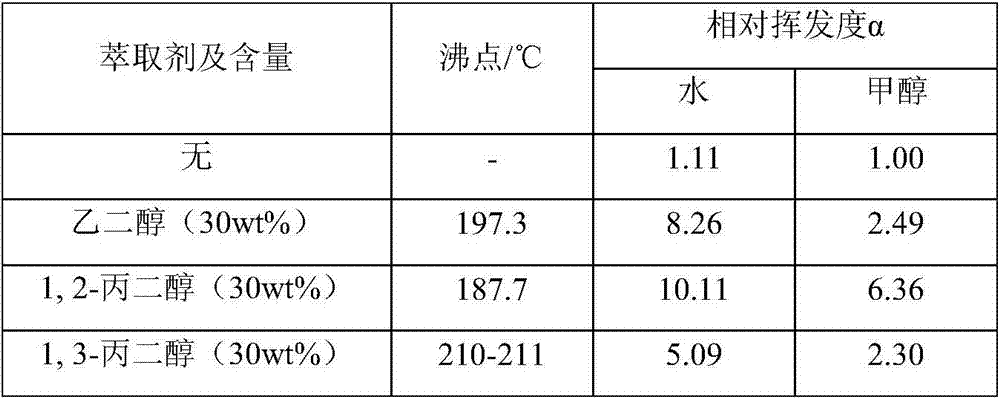

[0048] The method flow is as follows figure 1 As shown, it contains water, acetaldehyde, propionaldehyde, methanol and other oxygenates, propylene and other C 3 ~C 4 Light hydrocarbons, 2-methylpentane, etc. C 5 ~C 6 The crude propylene oxide (stream 1) of hydrocarbon impurity, flow rate is 10t / h, and the extraction agent propylene glycol (stream 2) that reclaims heat exchange to 70 ℃, after heat exchange, crude propylene oxide (stream 4) from 100 towers Feed from the lower part, the temperature of the extractant propylene glycol (stream 3) after heat exchange is about 150 °C, feed from the upper part of the tower, extract and rectify to remove water, propionaldehyde, acetone, 3-methyl contained in the crude propylene oxide Pentane and other impurities. The composition and content of crude propylene oxide (stream 1) are shown in Table 3:

[0049] table 3

[0050] composition

Content, wt

0.99

1200ppm ...

Embodiment 2

[0061] The method flow is as follows figure 1 As shown, it contains water, acetaldehyde, propionaldehyde, methanol and other oxygenates, propylene and other C 3 ~C 4 Light hydrocarbons, 2-methylpentane, etc. C 5 ~C 6 The crude propylene oxide (stream 1) of hydrocarbon impurity, flow rate is 10t / h, and the extraction agent propylene glycol (stream 2) that reclaims heat exchange to 80 ℃, after heat exchange, crude propylene oxide (stream 4) from 100 towers Feed from the lower part, the temperature of the extractant propylene glycol (stream 3) after heat exchange is about 160 ° C, feed from the upper part of the tower, extract and rectify to remove water, propionaldehyde, acetone, 3-methyl contained in the crude propylene oxide Pentane and other impurities. The composition and content of crude propylene oxide (stream 1) are shown in Table 4:

[0062] Table 4

[0063] composition

Content, wt

0.985

2100ppm ...

Embodiment 3

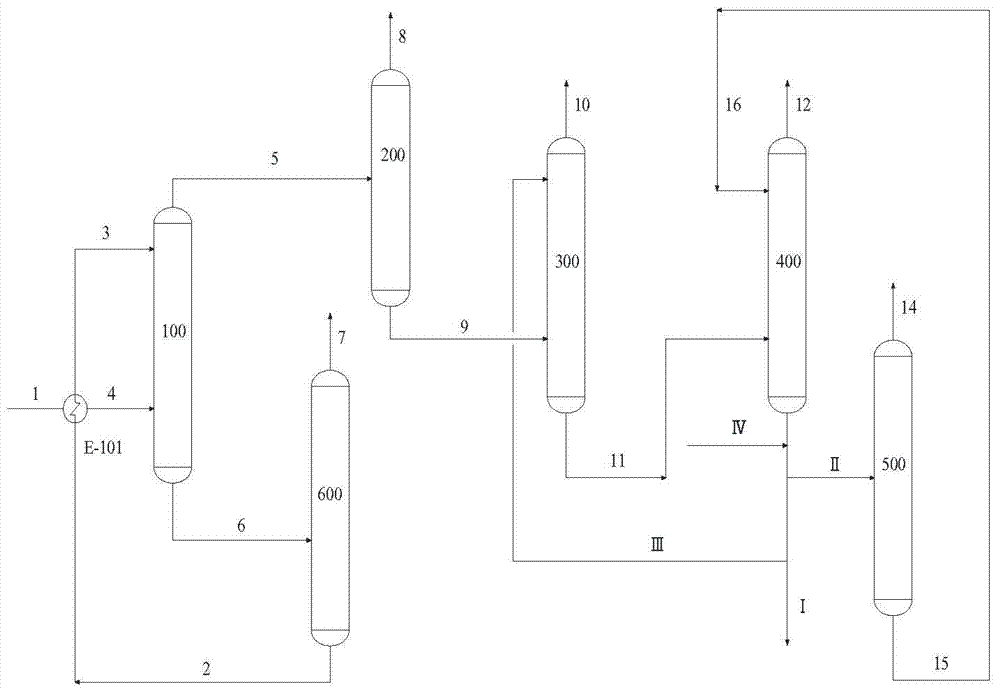

[0073] The method flow is as follows figure 2Shown, 400 tower still liquids are divided into 3 parts, and stream I (10%) directly circulates to ethylbenzene peroxidation unit as reaction raw material, stream II (30%) goes to 500 towers, and stream III (60%) goes to 300 towers as Extractant, stream IV is supplementary fresh ethylbenzene, and the flow rate is the same as stream I.

[0074] All the other implementations are the same as in Example 1, and the energy consumption is nearly 60% lower than that of the 500 towers in Example 1.

[0075] Propylene oxide content ≥ 99.9wt% in logistics 15, total aldehyde (calculated as propionaldehyde+acetaldehyde) 5mg / kg, hydrocarbon impurity is lower than 10ppm, impurity content such as acetone, water is negligible, and propylene oxide recovery rate reaches 99.5%.

[0076] As can be seen from the above, the implementation of the present invention can separate and obtain the polymer grade propylene oxide qualified product in an economic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com