Epoxidation cyclic method for preparing epoxy propane from ethylbenzene hydroperoxide and propylene

A technology of ethylbenzene hydrogen peroxide and propylene oxide, which is applied in chemical recovery, organic chemistry, etc., can solve the problems of rising reaction temperature, achieve the effects of increasing reaction temperature, increasing the proportion of propylene, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

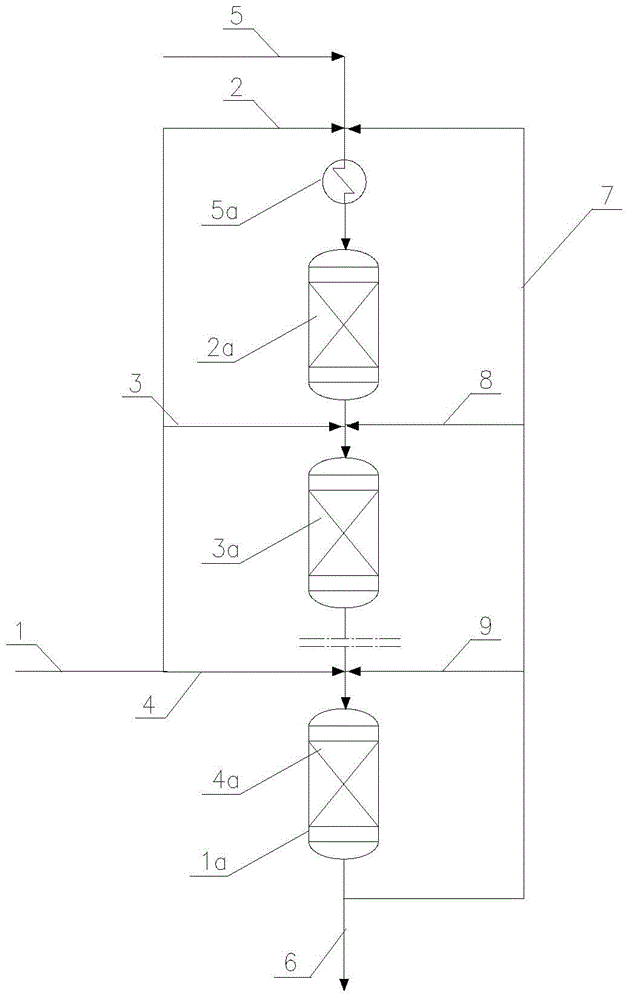

[0037] according to figure 1 The technical scheme shown, raw material contains the hydrogen peroxide ethylbenzene mixture of 19.34% weight concentration, and flow rate is 162367.5 kilograms / hour, is divided into two shares in proportion, enters the adiabatic fixed-bed reactor of two serial multi-bed catalysts respectively, raw material Propylene flow rate 10987.6 kg / hour in II, circulating propylene 103863.5 kg / hour, recycle stream I flow rate of peroxidation reaction product 69304.5 kg / hour, mixed with the hydrogen peroxide ethylbenzene mixture entering the catalyst bed of the first reactor, in Under the condition of reaction temperature 76℃ and reaction pressure 2.9MPaG, with Ti / SiO 2 Catalyst contact, liquid-phase epoxidation reaction to generate propylene oxide, methyl benzyl alcohol and other by-products; reactants flowing out of the first reactor and ethylbenzene hydrogen peroxide mixture entering the second reactor, cyclic epoxidation reaction The product 115508 kg / h i...

Embodiment 2

[0039] Same as [Example 1], only change the flow rate of the recycle stream: the recycle propylene flow rate is 69242.5 kg / h, the recycle epoxidation reaction product entering the first reactor is 60649.4 kg / h, and the recycle epoxidation product entering the second reactor is 60649.4 kg / h. Reaction product 101082.4 kg / hour, other [Example 1]. Hydrogen peroxide ethylbenzene weight space velocity 4.1hr -1 , the mol ratio of total propylene and ethylbenzene hydrogen peroxide is 8.03, the mol ratio of the propylene of the first reactor and the second reactor inlet and ethylbenzene hydrogen peroxide then reaches 23.3 and 21.1, the first reactor and the second The outlet temperatures of the reactors were 89.0°C and 88.3°C respectively, the total conversion rate of ethylbenzene hydroperoxide was 99.2%, and the molar selectivity of propylene oxide was 99.11%.

Embodiment 3

[0041] Same as [Example 1], only the reactor form is changed: two adiabatic fixed-bed reactors with a single-bed catalyst are connected in series, and the others are the same as [Example 1]. Hydrogen peroxide ethylbenzene weight space velocity 4.1hr -1 , the mol ratio of total propylene and ethylbenzene hydroperoxide is 11.52, the mol ratio of the propylene of the first reactor and the second reactor inlet and ethylbenzene hydrogen peroxide then reaches 33.6 and 31.0, the first reactor and the second The outlet temperatures of the reactors were 87.4°C and 86.6°C respectively, the total conversion rate of ethylbenzene hydroperoxide was 99.2%, and the molar selectivity of propylene oxide was 99.15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com