A device and method for oxidation of organic matter

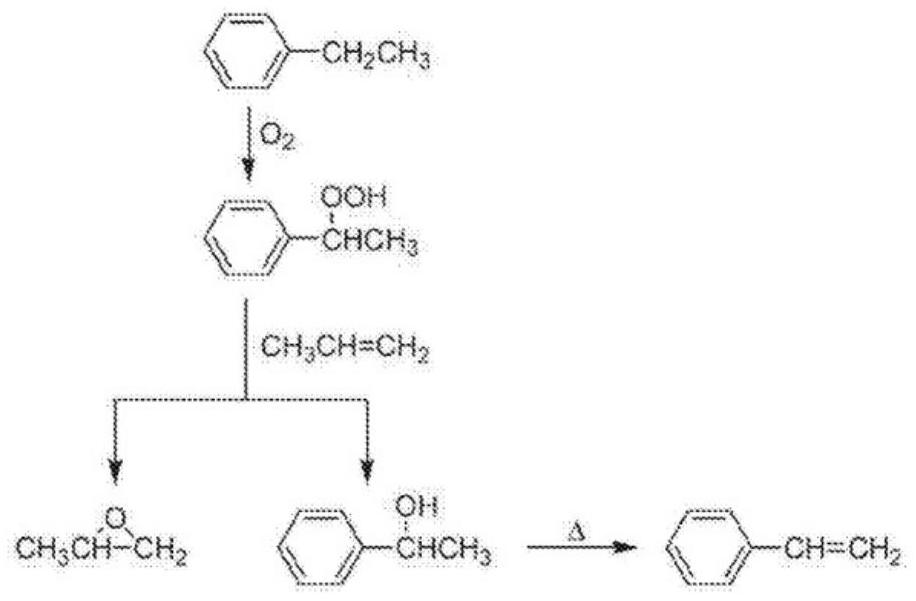

A technology of ethylbenzene hydroperoxide and bubbling reactor, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problem of decreased production capacity of equipment, insufficient contact between gas and liquid, and return of liquid phase. mixed problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

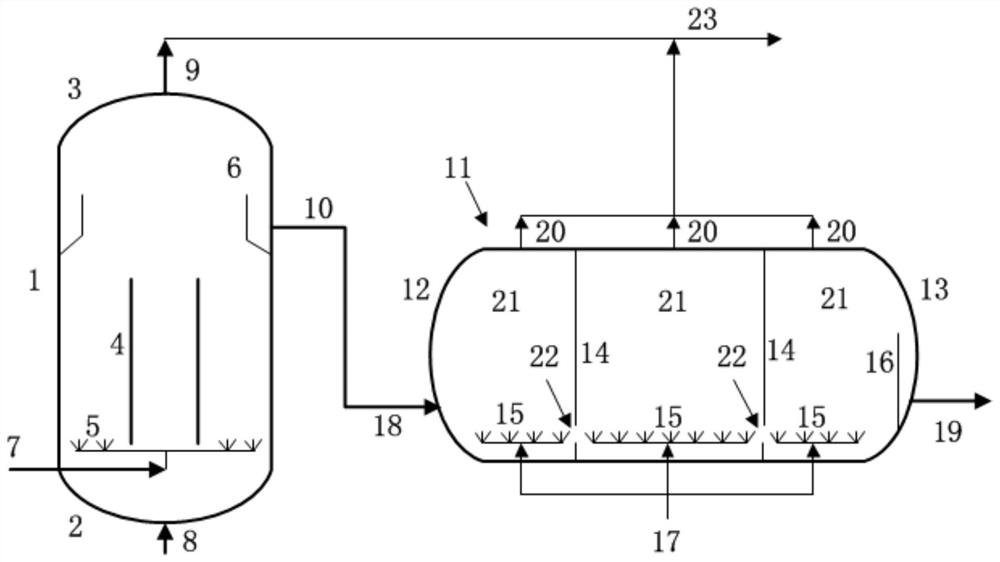

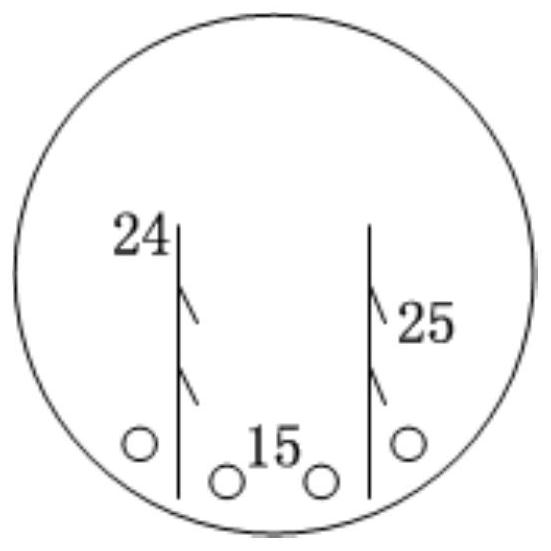

[0061] use as figure 1 In the shown device, the diameter of the vertical bubbling reactor 1 is about 0.8 meters, and the total height is about 3 meters. The diameter of the guide tube 4 is 0.3 meters, and the height is 1.2 meters. Arranged between the guide tube and the inner wall of the reactor, the opening diameter is 2mm, and the opening ratio is 0.02%. The horizontal bubble reactor 11 has a diameter of about 1.6 meters and a length of about 3.66 meters. The reactor was divided into four reaction compartments 21 by using three partitions 14, and a liquid flow channel 22 with a diameter of 110 mm was left at the bottom of the partitions 14. Each compartment 21 contains 4 gas distribution porous tubes, the gas distribution porous tubes are evenly and symmetrically distributed along the arc of the lower part of the reactor, the opening diameter is 2mm, and the opening ratio is 0.05%. Such as figure 2 As shown, two symmetrical vertical baffles are arranged on the inside of t...

Embodiment 2

[0065] Change the diameter of the guide tube 4 in Example 1 to 0.5 meters, and the height of the guide tube to 1.0 meters, change the opening ratio of the gas distributor in the horizontal bubbling reactor to 10%, repeat the experiment in Example 1, and control the vertical The temperature of the horizontal bubble reactor is 138°C, the reaction temperature of the second compartment of the horizontal bubble reactor is 136°C, the reaction temperature of the third compartment is 135°C, the reaction temperature of the fourth compartment is 134°C, and the gas phase pressure of the reactor is about 3.5barG .

[0066] Adopt above-mentioned conditions to carry out experiment, the reaction liquid mixture that the outlet of reactor liquid phase can obtain ethylbenzene hydroperoxide content is about 7.3wt%, and vertical bubbling reactor outlet ethylbenzene hydroperoxide concentration is 1.33%, ethylbenzene Hydroperoxide selectivity is about 88.4%.

Embodiment 3

[0076] Using the same reactor structure as in Example 1, in this example the liquid phase flowing out from the vertical reactor directly enters the first compartment of the horizontal reactor, and then flows through the second, third and fourth compartments in sequence. In this example, the total residence time remains the same as Example 1 by adjusting the reactor liquid level. Other reaction conditions are all identical with embodiment 1, repeat the experiment of embodiment 1.

[0077] Under above-mentioned conditions, can obtain the reaction liquid mixture that ethylbenzene hydroperoxide content is about 7.2wt% at reactor liquid phase outlet, and vertical bubble reactor outlet ethylbenzene hydroperoxide concentration is about 1.21%, ethylbenzene The overall selectivity to hydroperoxides is about 88.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com