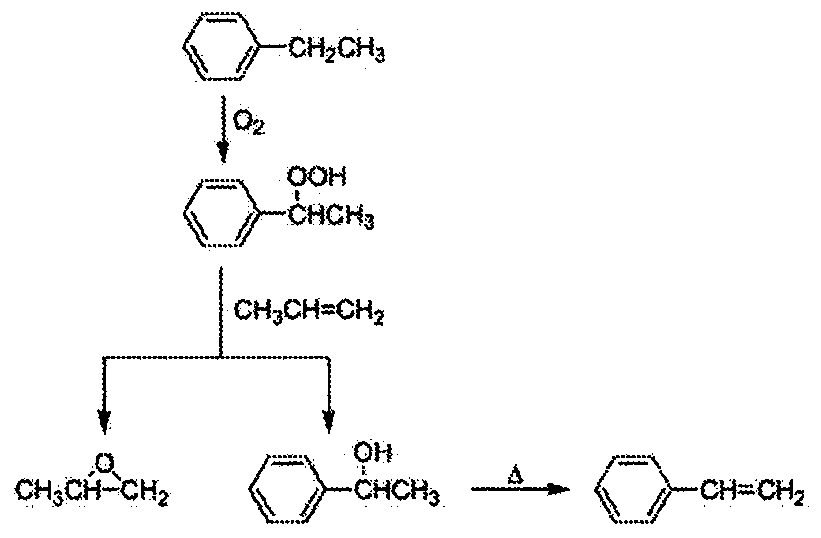

Method for preparing ethylbenzene hydroperoxide by liquid-phase peroxidation of ethylbenzene and preparation method of propylene oxide

A technology of ethylbenzene hydroperoxide and liquid-phase peroxidation of ethylbenzene, which is applied in the direction of preparation of peroxygen compounds, preparation of organic compounds, chemical instruments and methods, etc., can solve the loss of EBHP, increase the risk of PMA emulsification, and destabilize sexual issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

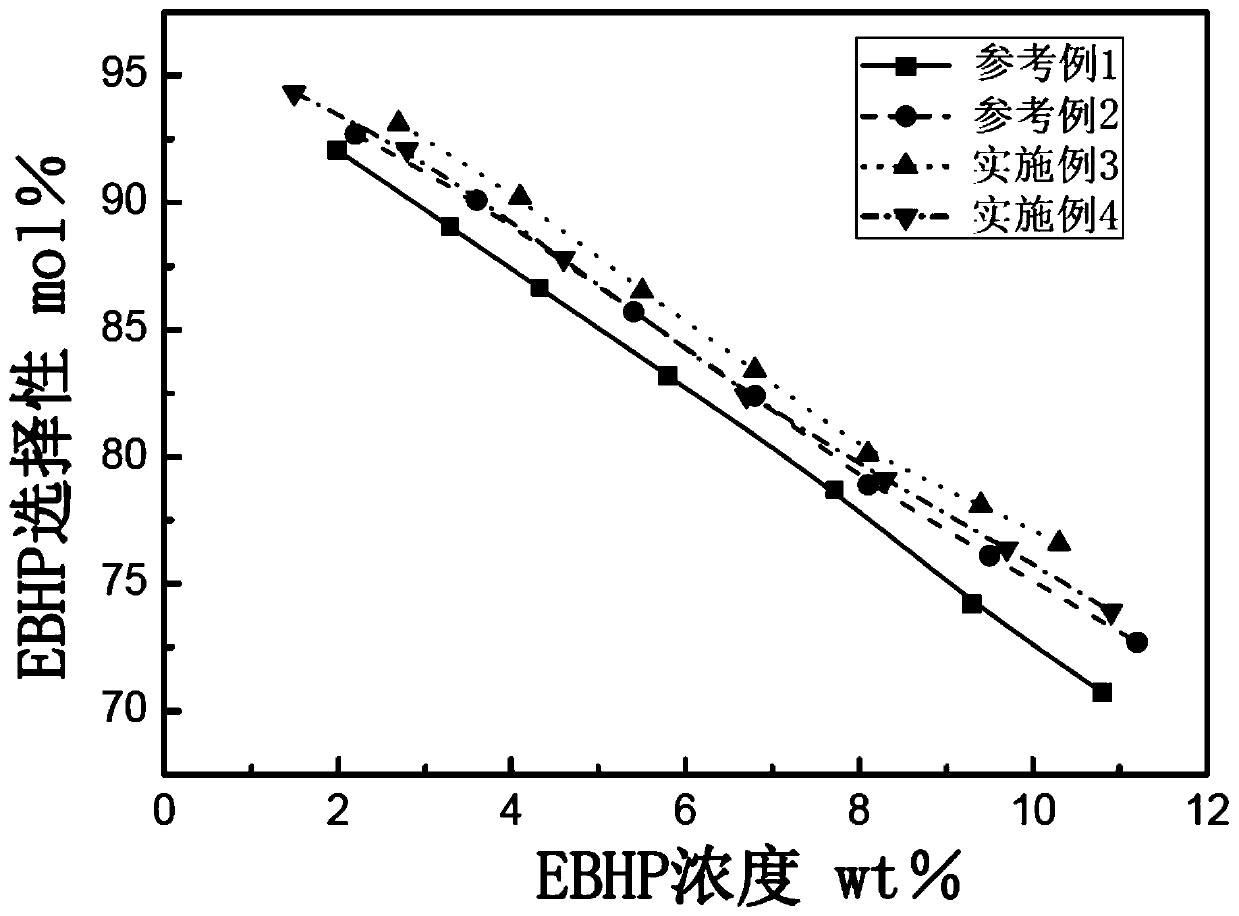

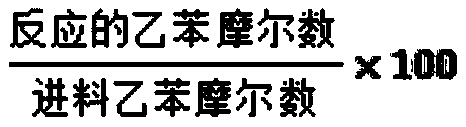

[0045] Measure 250ml of ethylbenzene into the reaction kettle and seal it. The air in the reactor was replaced by introducing nitrogen several times, and the pressure was increased to about 1 barG, the reactor inlet was closed, and the back pressure valve of the reactor tail gas outlet was adjusted to a tightly closed state. Turn on the reactor's mechanical stirring, electric heating, and tail gas condenser pipe circulating water, turn on the computer temperature control program and set the temperature in the reactor to 150°C, and the stirring speed to 800r / min. When the temperature in the reactor reaches the set value, open the air inlet valve, start the reaction and record the time, and at the same time take a sample to obtain the first sample. Thereafter, samples were taken every 5-20 minutes, solvent and nitrogen purge were required before and after each sampling, and the total reaction time was 3.5 hours. Data during the experiment (temperature in the kettle, air flow, O...

reference example 2

[0048] Measure 250ml of ethylbenzene, add 10ppm (based on the mass of ethylbenzene) sodium hydroxide to make a solution, put the above solution into the reaction kettle and seal it. Other experimental procedures are the same as in Example 1. According to the analysis results, the selectivity of EBHP under different EBHP concentrations can be obtained, and the results are shown in the following table:

[0049]

Embodiment 3

[0051] Measure 250ml of ethylbenzene, add 10ppm (based on the quality of ethylbenzene) of guanidine carbonate and configure it into a solution, add the above solution into the reaction kettle and seal it. Other experimental procedures are the same as in Example 1. According to the analysis results, the selectivity of EBHP under different EBHP concentrations can be obtained, and the results are shown in the following table:

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com