Preparation method of porous silicon coated zero-valent iron material for in-situ remediation of groundwater pollution

A technology for groundwater pollution and in-situ remediation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

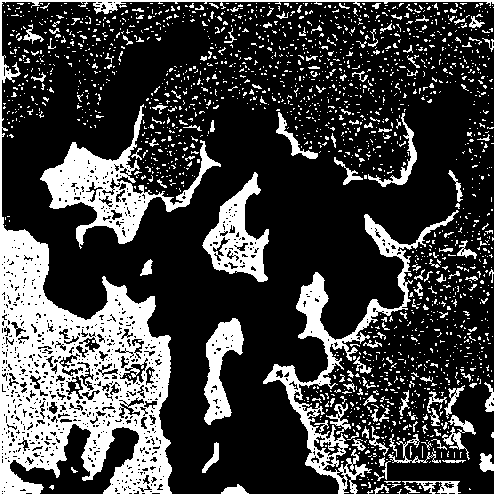

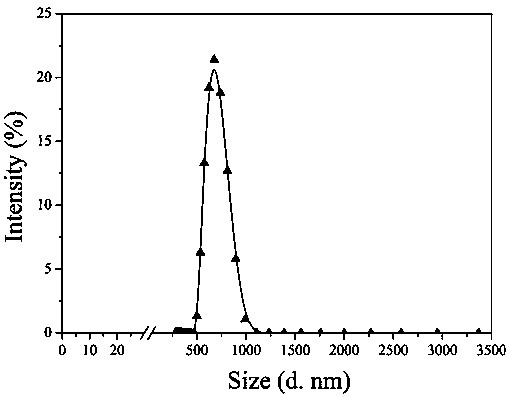

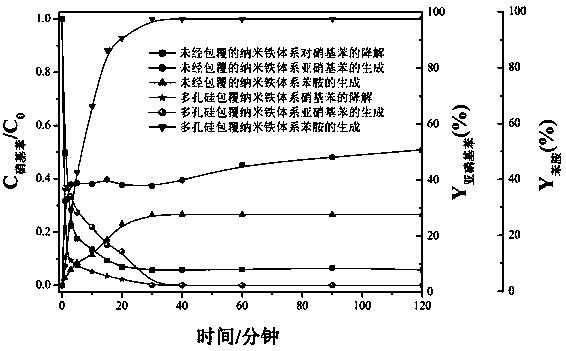

[0033] see Figure 1 to Figure 5 As shown in the present invention, the preparation method of the porous silicon-coated zero-valent iron material for in-situ remediation of groundwater pollution is to add ferric chloride to a mixed solution of ethanol, water and ethyl orthosilicate, and then add dropwise after mixing evenly. The mixed solution of potassium borohydride or sodium borohydride and sodium hydroxide is magnetically separated, washed and dried in vacuum after the reaction. The preparation process is carried out under the protection of inert gas. The prepared porous silicon-coated zero-valent iron material has a large specific surface area and an actual particle size of 0.5–0.8 μm, which is within the optimal size range for colloidal particles to migrate through the porous medium of the aquifer, compared with uncoated zero-valent iron. , its activity and migration ability in the porous media of aquifers have been greatly improved, which overcomes the disadvantage tha...

Embodiment 2

[0037] A preparation of a porous silicon-coated zero-valent iron material that can be used for in-situ remediation of groundwater pollution, the preparation process specifically includes the following steps:

[0038] (1) Add 0.5 mL of ethyl orthosilicate to 150 mL of a mixed solution of water and anhydrous ethanol (volume ratio is 1:3), stir evenly, then add 0.17 g of anhydrous ferric chloride, and continue to stir 10 minutes;

[0039] (2) Preparation of BH 4 - 20 mL of potassium borohydride or a mixed solution of sodium borohydride and sodium hydroxide with a concentration of 0.56 mol / L and a concentration of sodium hydroxide of 2.5 mol / L was added dropwise to step (1) at a rate of 6 mL / min. ) in the solution prepared by adding dropwise while stirring (the stirring speed is 1000 r / min), and continuing to stir for 1 h after the dropwise addition. Unreacted ethyl orthosilicate and excess borohydride were washed away with a mixed solution of ethanol and water, and finally vac...

Embodiment 3

[0041] A preparation of a porous silicon-coated zero-valent iron material that can be used for in-situ remediation of groundwater pollution, the preparation process specifically includes the following steps:

[0042] (1) Add 0.45 mL of ethyl orthosilicate to 120 mL of a mixed solution of water and anhydrous ethanol (volume ratio is 1:2.3), stir evenly, then add 0.17 g of anhydrous ferric chloride, continue stirring 10 minutes;

[0043] (2) Preparation of BH 4 - 20 mL of potassium borohydride or a mixed solution of sodium borohydride and sodium hydroxide with a concentration of 0.56 mol / L and a concentration of sodium hydroxide of 5 mol / L was added dropwise to step (1) at a rate of 5 mL / min. ) in the solution prepared by adding dropwise while stirring, and continued stirring for 1 h after the dropwise addition. The entire reaction process was carried out under the protection of inert gas, and the obtained black solid was separated by magnetic separation, and then washed with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electric potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com