Multi-functional pretreatment refining agent

A refining agent, multi-functional technology, applied in fiber processing, textiles and papermaking, etc., can solve problems such as environmental pollution, achieve the effect of easy biodegradation, promote enzyme activity, and reduce COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: a kind of multifunctional pretreatment refining agent, by weight, comprises following component 30 parts of natural nonionic surfactants, 10 parts of nonionic mixtures, 20 parts of acrylic acid-hydroxyethyl acrylate copolymers, 10 parts of clay , the non-ionic mixture includes sorbic acid ester and citric acid, the ratio of sorbic acid ester and citric acid is 1:1, the natural non-ionic surfactant is tea saponin, and the clay is bentonite, which is distributed in the form of fine particle powder before the multifunctional In treating the refining agent, the above-mentioned components are weighed in parts by weight and then mixed and compounded.

[0030] Acrylic acid-hydroxyethyl acrylate copolymer, it is prepared by following method:

[0031] Step S1, taking acrylic acid and hydroxyethyl acrylate, adding water at 55-60°C, and mixing;

[0032] Step S2, taking ammonium persulfate, adding water at 25-30°C, and mixing;

[0033] Step S3, taking water, ethanol...

Embodiment 2

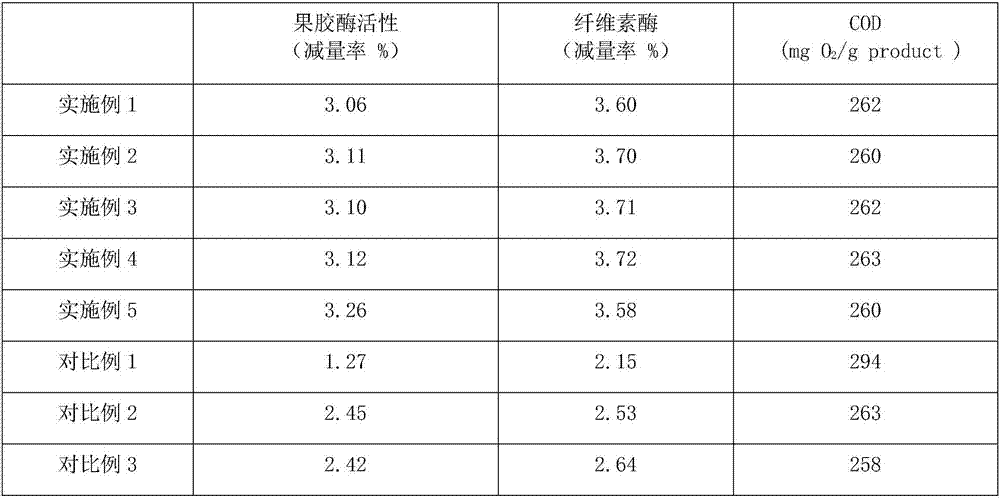

[0040] Embodiment 2: A kind of multifunctional pretreatment refining agent, the difference with embodiment 1 is that in the pectinase activity test, the concentration of the multifunctional pretreatment refining agent is 30%, and in the cellulose activity test, the multifunctional pretreatment refining agent is 30%. The concentration of the agent is 30%. And measure COD, list test result in Table 1.

Embodiment 3

[0041] Embodiment 3: a kind of multifunctional pretreatment refining agent, the difference with embodiment 2 is that multifunctional pretreatment refining agent component comprises 40 parts of natural nonionic surfactants, 20 parts of nonionic mixtures, 30 parts of acrylic acid - Hydroxyethyl acrylate copolymer, 20 parts clay. And carry out pectinase activity test, cellulase activity test, measure COD, list test result in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com