Preparation method of three dimensional graded porous activated carbon material

A technology of hierarchical porous and activated carbon, which is applied in the field of preparation of three-dimensional hierarchical porous activated carbon, which can solve the problems of harsh preparation conditions, long preparation cycle, and many steps, and achieve the effect of low operating cost, ingenious design of ideas, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for preparing a three-dimensional hierarchical porous activated carbon material, comprising the steps of:

[0043] 1) Dissolve 50mgKOH in 50mL of water and sonicate for 0.5min in a water bath ultrasonicator with a power set at 50W to obtain a KOH aqueous solution with a concentration of 0.001g / mL;

[0044] 2) Add 25mg of Resol-type phenolic resin to the above KOH aqueous solution, and stir for 5 minutes with magnetic force at a speed of 100 rpm;

[0045] 3) Put the mixture obtained in step 2) into a quartz tube furnace, pass through nitrogen protection, and carbonize at 400°C for 10 hours;

[0046] 4) After the product obtained by carbonization was cooled to room temperature, it was washed several times with dilute hydrochloric acid and water in sequence, and then dried at room temperature for 48 hours.

[0047] Analysis by scanning electron microscopy, nitrogen adsorption and desorption, and mercury intrusion method shows that the activated carbon material ob...

Embodiment 2

[0049] A method for preparing a three-dimensional hierarchical porous activated carbon material, comprising the steps of:

[0050] 1) Dissolve 1gKOH in 1mL water, and sonicate for 5min in a water bath ultrasonicator with power set at 150W to obtain a KOH aqueous solution with a concentration of 1g / mL;

[0051] 2) Add 0.4g of Resol type phenolic resin to the above KOH aqueous solution, stir for 15min with magnetic force, and the rotation speed is 200rpm;

[0052] 3) Put the mixture obtained in step 2) into a quartz tube furnace, pass through nitrogen protection, and carbonize at 700 ° C for 120 min;

[0053] 4) After the carbonized product was cooled to room temperature, it was washed several times with dilute hydrochloric acid and water in sequence, and then dried at 100°C for 12 hours.

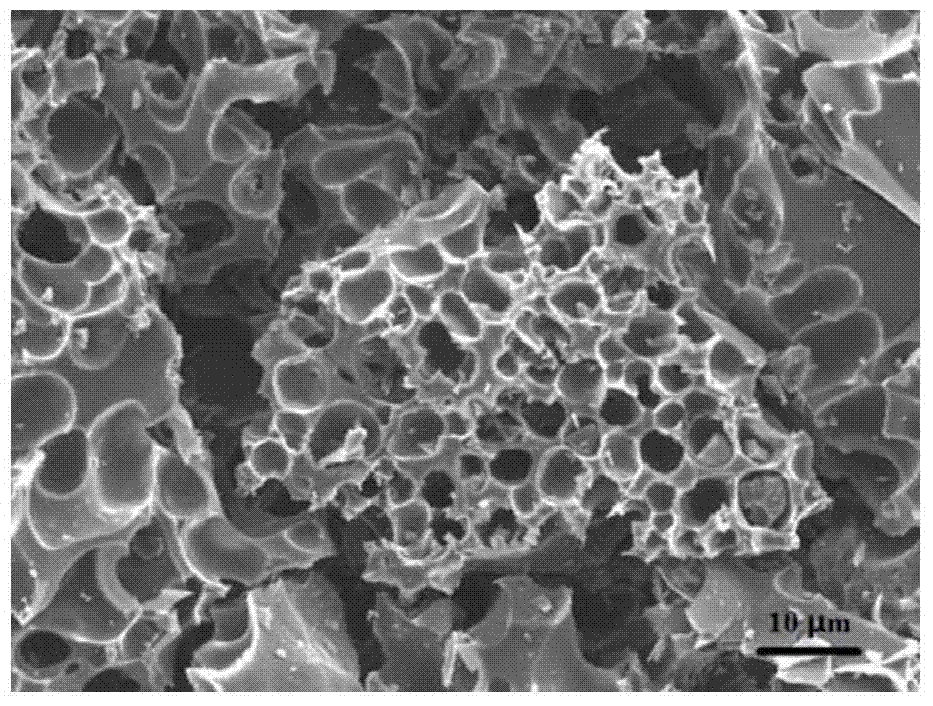

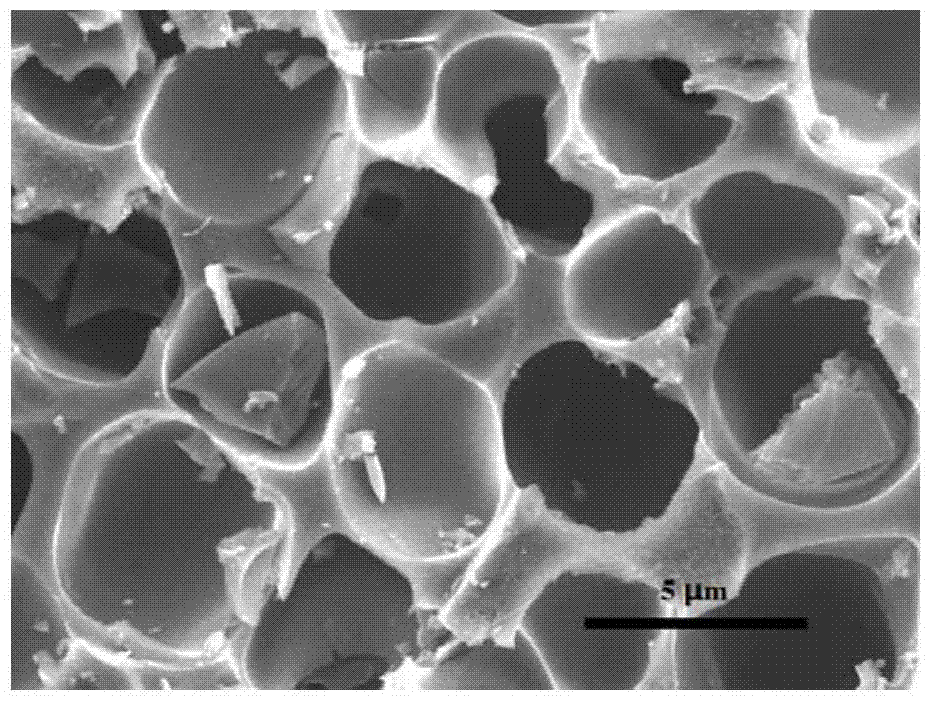

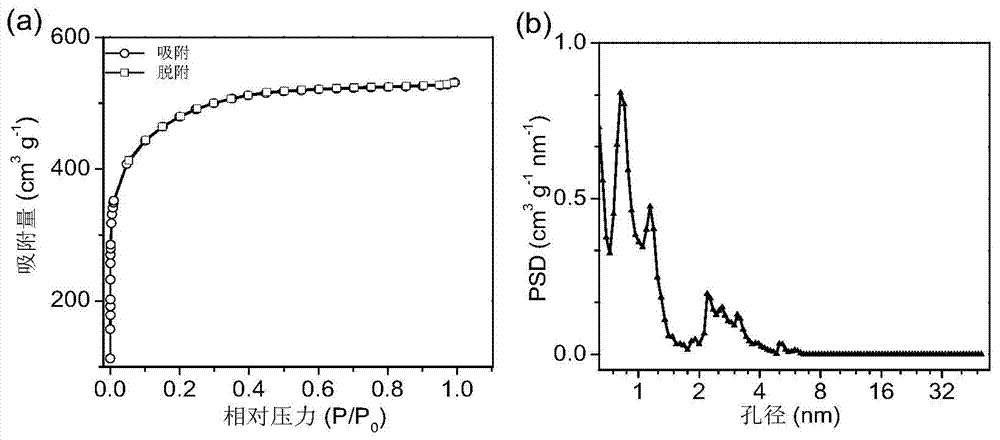

[0054] figure 1 It is a scanning electron microscope picture of the three-dimensional hierarchical porous carbon material obtained in this embodiment; figure 2 for figure 1 Partial magni...

Embodiment 3

[0057] A method for preparing a three-dimensional hierarchical porous activated carbon material, comprising the steps of:

[0058] 1) Add 10gKOH into 1mL water, stir for 30min with magnetic force at 250rpm, and obtain a KOH / water mixture with a concentration of 10g / mL;

[0059] 2) Add 0.5g Resol type phenolic resin to the above KOH / water mixture, stir for 60min with magnetic force, and the speed is 300 rpm;

[0060] 3) Put the mixture obtained in step 2) into a quartz tube furnace, pass through argon protection, and carbonize at 1500°C for 0.01h;

[0061] 4) After the carbonized product was cooled to room temperature, it was washed several times with dilute hydrochloric acid and water in sequence, and then dried at 150°C for 12 hours.

[0062] Analysis by scanning electron microscopy, nitrogen adsorption and desorption, and mercury porosimetry shows that the activated carbon material obtained in this example has a three-dimensional hierarchical porous structure, with a macrop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Large hole diameter | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com