Gas dechlorination agent and preparation method thereof

A dechlorination agent and gas technology, which is applied in the field of gas dechlorination agent and its preparation, can solve the problems of equipment corrosion, application limitation and complicated operation of the regeneration circuit, and achieves high-pressure crushing strength, increased specific surface area, and increased pore volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The preparation method of the gas dechlorination agent provided by the present invention comprises mixing alkaline earth metal oxides or their precursors, alumina or its precursors, and bentonite as raw materials, and then adding a pore-enlarging agent and mixing evenly. Baking at 700°C.

[0017] The alkaline earth metal oxide described in the above method is preferably calcium oxide, and the precursor of the alkaline earth metal oxide is preferably calcium hydroxide, calcium carbonate or calcium bicarbonate. The precursor of alumina is preferably pseudoboehmite or alumina sol.

[0018] The pore-enlarging agent is preferably methyl cellulose or ammonium bicarbonate, and the amount of the pore-enlarging agent added is 0.5-15% by mass of the total amount of raw materials, preferably 1.0-10% by mass.

[0019] In the preparation method of the dechlorination agent, after mixing the raw materials and adding the pore-enlarging agent, it is preferable to add the extrusion aid....

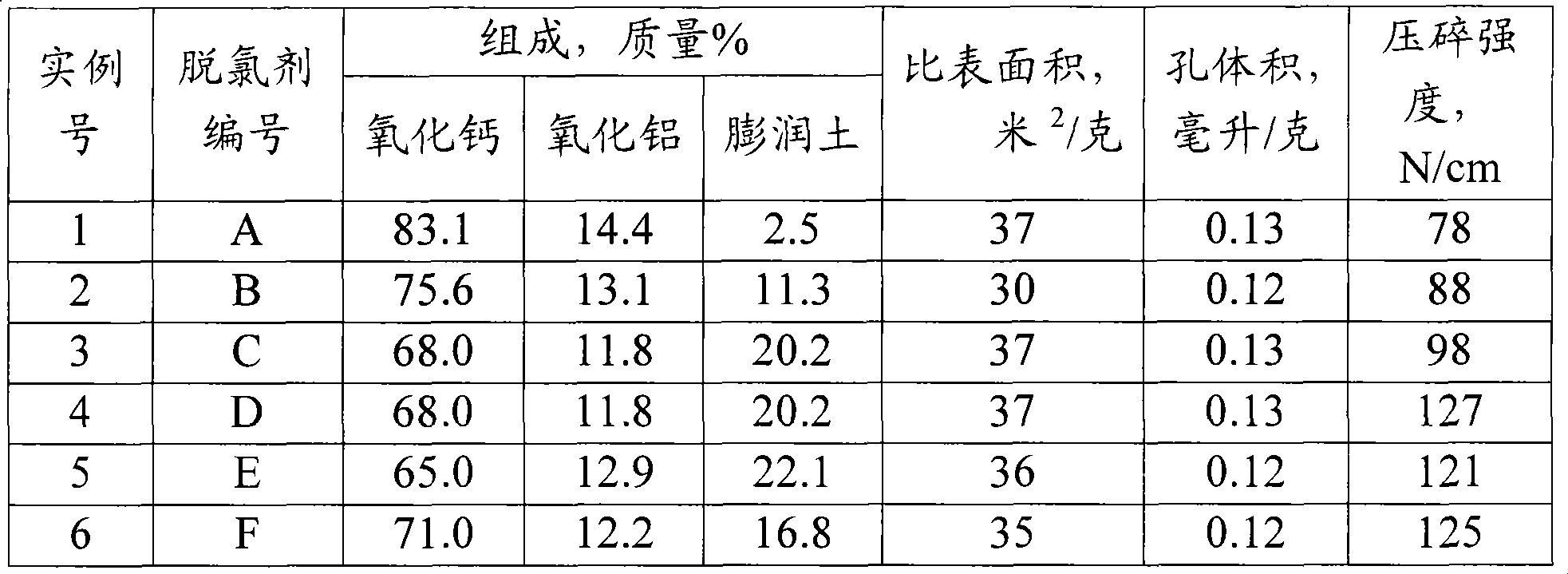

example 1

[0022] (1) Preparation of dechlorination agent

[0023] Get 15 grams of pseudo-boehmite (aluminum oxide content is 70 mass %, the PURAL that Germany Sasol company produces SB), 2 grams of calcium-based bentonite (dry base solid content is 90 mass %, Henan Xinyang Daye Bentonite Co., Ltd.) and 80 grams of calcium hydroxide are mixed to make raw materials, add 2 grams of methylcellulose (Shandong Ruitai Chemical Co., Ltd. Production) and 2 gram of Squatia powder mix homogeneously, then add 15ml concentration and be that the nitric acid of 33 mass % and 45ml deionized water mix and knead evenly, extrusion molding, 120 ℃ of drying 2 hours, 650 ℃ of roasting 4 hours, obtain dechlorination agent A , and its composition and physical properties are listed in Table 1.

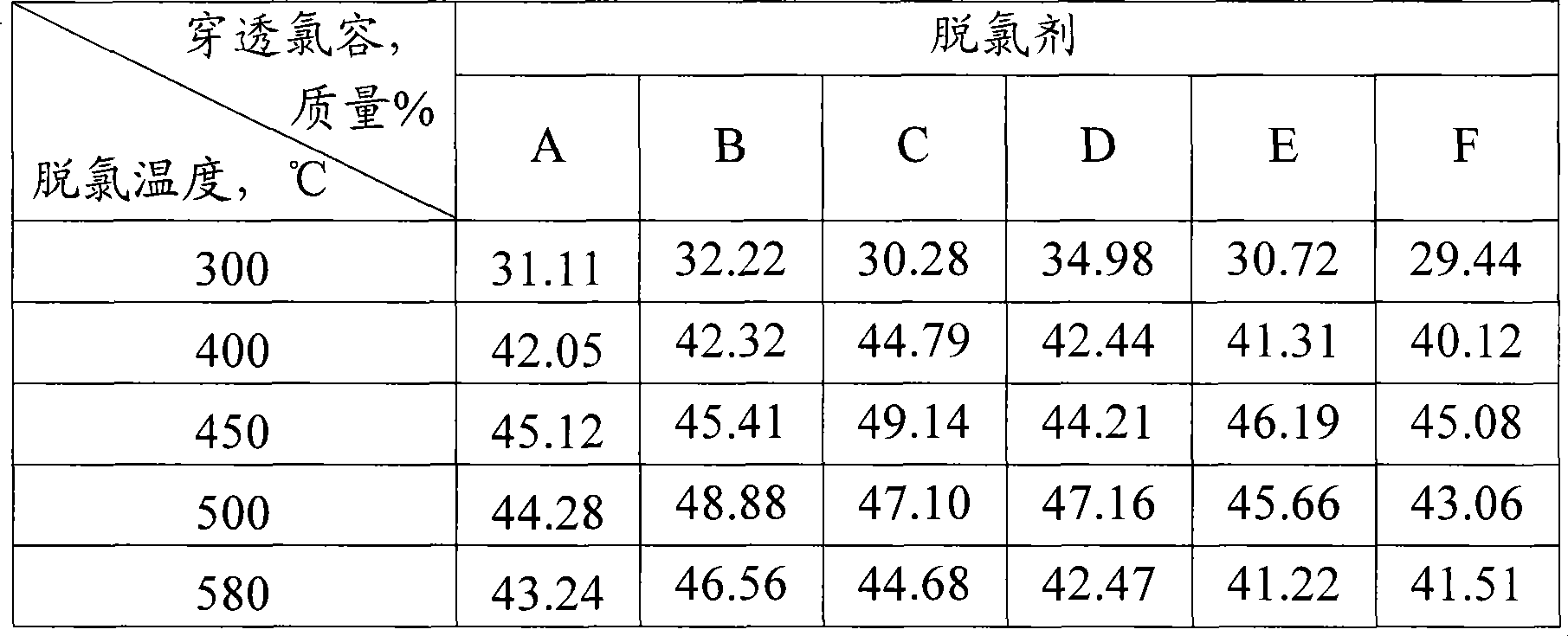

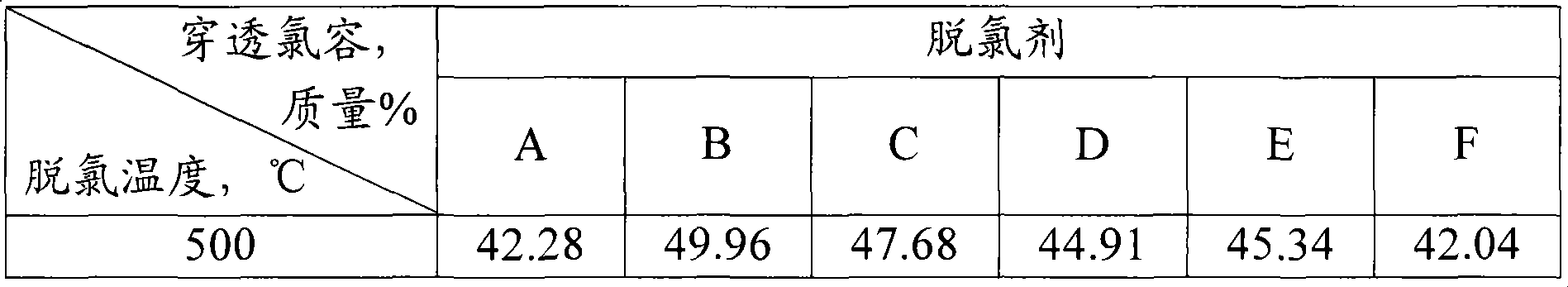

[0024] (2) Evaluation of dechlorination agent performance

[0025] Grind the dechlorination agent finely, take 150-420 micron particles and put them into a quartz glass tube with an inner diameter of 6 mm, and use th...

example 2

[0028] Prepare dechlorination agent by the method of example 1 (1) step, and difference is that the addition of bentonite is 10 grams, and the composition and physical property of the dechlorination agent B that makes are shown in Table 1.

[0029] The dechlorination performance of dechlorination agent B is evaluated by the method of example 1 (2) step, and the penetration chlorine capacity of dechlorination agent B at each adsorption temperature is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Crushing strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com